In recent years, it is widely accepted that based on an ideal amino acid profile, a moderate reduction of dietary crude protein (CP), 20 to 30 g/kg, will not compromise broiler chicken performance.

These reduced CP levels are usually achieved by increasing feed grains such as wheat inclusion at the expense of soybean meal, relatively more starch replacing fat as the non-protein energy source. It is reported that increased non-starch polysaccharides (NSP) presented in wheat will enhance faecal bile acids loss, resulting in either increased bile acids pool or bile acids deficiency.

Traditionally bile acids are considered to be bio-surfactants, assisting intestinal digestion and absorption of lipids and fatty soluble vitamins such as Vitamin A, D, E and K, and thereby improving nutrient utilization. Recently it has been shown that bile acids act as regulators of gut microbiome and play a key role as signalling molecules by modulating cell proliferation, gene expression, lipid and glucose metabolism. To evaluate if the reduced CP diet could affect fat digestibility, the University of Sydney conducted a broiler chicken trial by adding the exogenous bile acids to both normal CP and reduced CP diets.

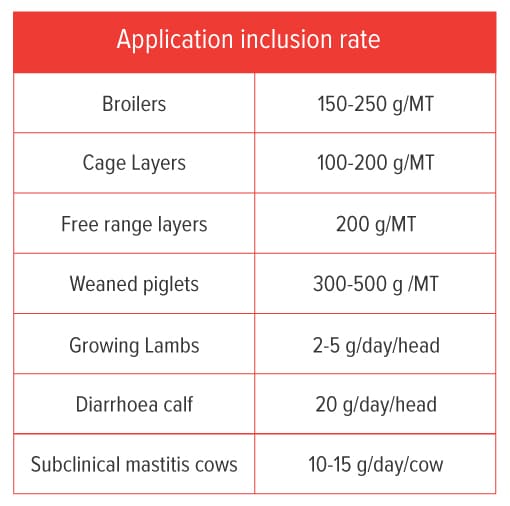

Standard, normal protein (SC) diets were formulated to meet or exceed the 2019 Aviagen Ross 308 nutrition specifications and reduced protein (RC) diets were formulated with a 3 g/kg CP reduction in the starter (0-14 d), grower (15-28) and finisher (29-42) phases. Another two treatments consisted of the SC and RC supplemented with the exogenous bile acids 200 mg/kg, respectively. All diets contained 1000 FTU phytase and 4000 U Xylanase.

Surprisingly, reducing 30 g/kg CP significantly depressed body weight gain and feed intake by 4.8 % and 2.8%, respectively (P < 0.01) although chicken performance fed on RP diets exceeded the Ross 2022 male performance objectives by 4.31% for weight gain (3361versus 3222 g) and was superior by 2.76% in FCR (1.475 versus 1.517). Figure 1 clearly showed that the current ideal amino acids profile resulted in significant lower plasma Valine, Isoleucine, Arginine, Leucine, tryptophan and histidine concentrations in RP diets, indicating that the current ideal amino acids profile could not support 30 g/kg CP reduction although it might achieve commercially satisfied performance.

Figure 1. Plasma AA concentrations in response to normal and reduced CP diets (log µg/ml)

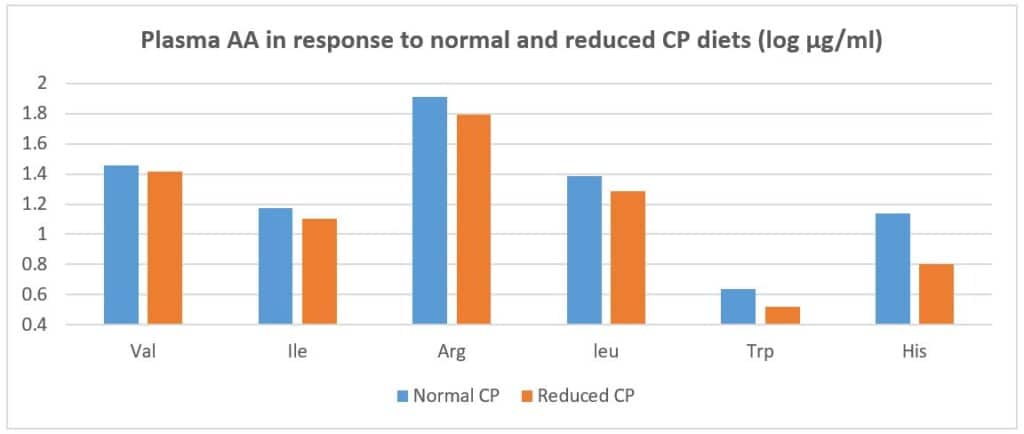

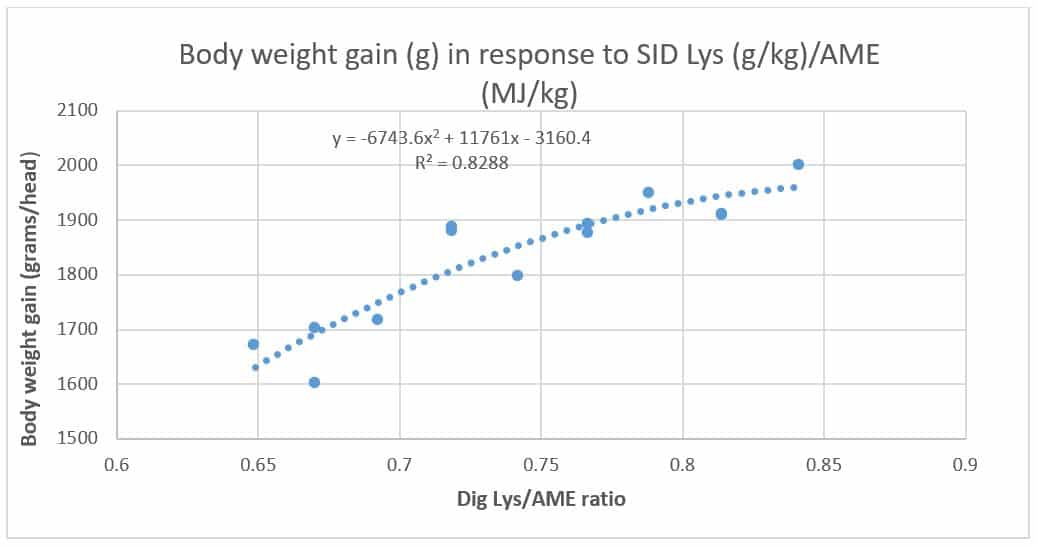

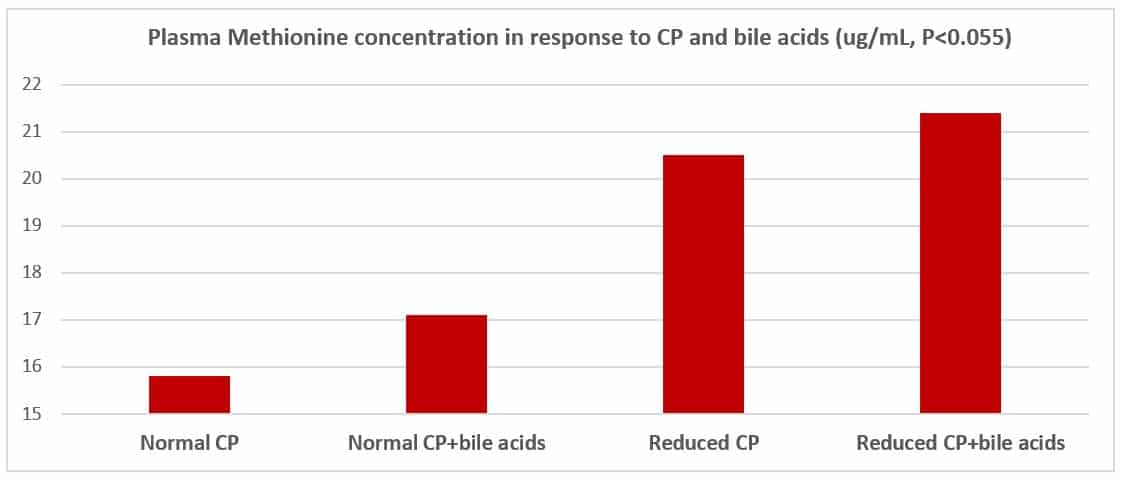

Interestingly, the addition of the exogenous bile acids had no effect on crude fat digestibility but significantly improved crude protein and dry matter digestibility (Table 1) possibly due to reduced endogenous bile taurine loss. In Table 1, it is also shown that adding bile acids to the RP diet, significantly reduced mortality rate (P < 0.003).

Table 1. The effect of dietary treatments on the mortality and digestibility of fat, CP and dry matter (%)

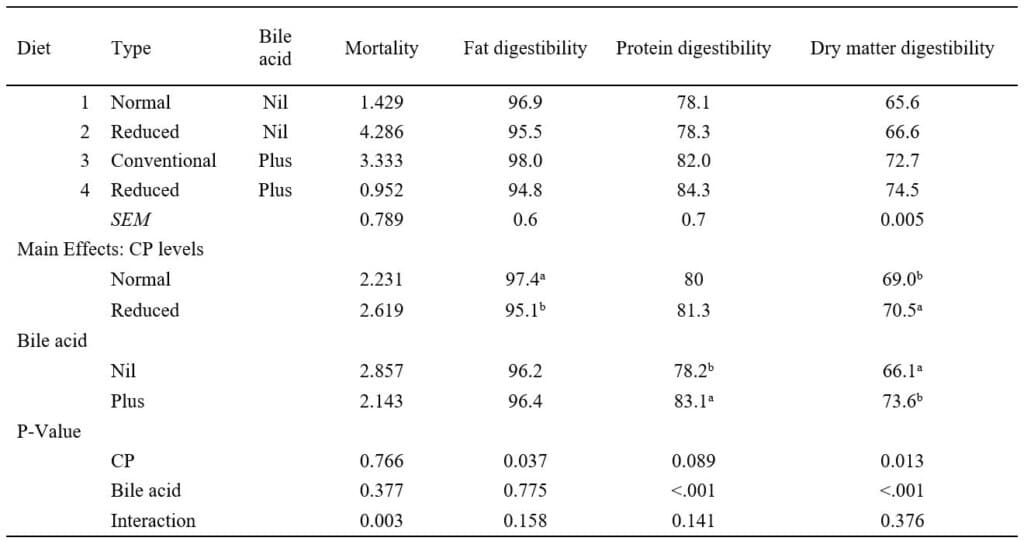

In RP diets, due to other amino acids such as valine, isoleucine and arginine limitation, dietary methionine becomes more surplus but adding bile acids significantly increased plasma methionine concentration (Figure 2). Therefore, the efficacy of bile acids may be related to dietary methionine concentration which could convert to taurine. In general, in grower period (15-28), adding the exogenous bile acids to a RP diet achieved the best chicken performance and FCR was improved by 5 points (Table 2).

Figure 2. Plasma Methionine concentration in response to dietary protein and bile acids addition (µg/mL)

Table 2. The effect of dietary protein levels and bile acids on growth performance (15-28 days)

A study compiled by our Redox Animal Nutritionists.

In recent years, the poultry and pig industry has been successfully developing reduced crude protein (CP) diets to reduce Nitrogen pollution and improve the litter quality. It is reported that 2.5%-unit crude protein reduction in poultry or pig diets will reduce ammonia by 25%. Considering 1 MT ammonia is equivalent to 2.11 MT carbon dioxide, this trend will have a tremendous impact on climate change. However, nutritionists need to do more to deal with reduced protein diets.

1. Reduced protein diets and limiting amino acids (AA)

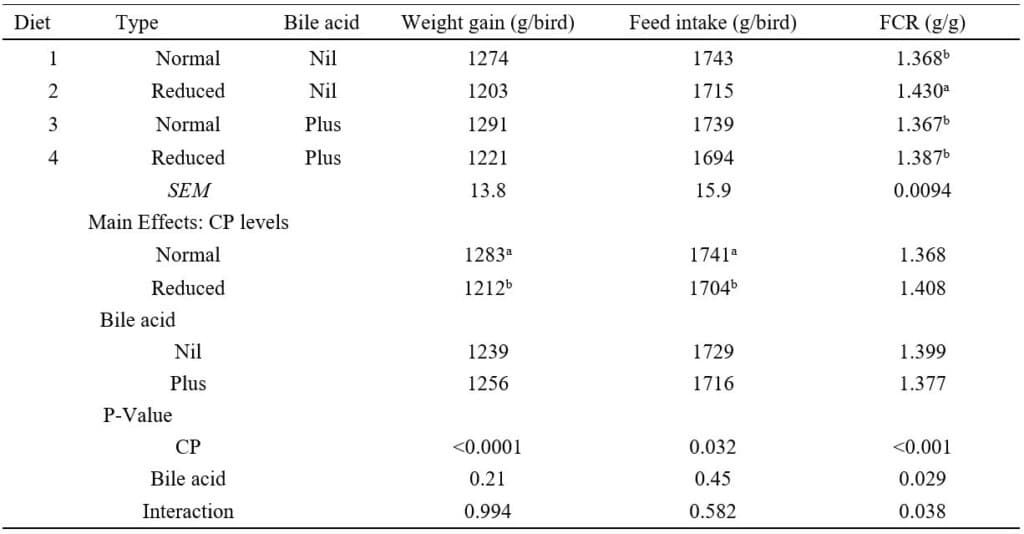

Traditionally, in wheat-soybean meal-based poultry diets, unbound crystalline L-methionine, L-Lysine and L-Threonine have been routinely added to meet chicken growth requirements. It is clear now that by further adding L-Valine, L-Isoleucine and L-Arginine, the crude protein level could be reduced by 1.5 to 2% unit but not compromise chicken performance. It is noticed that in reduced protein diets, dietary valine or arginine deficiency will result in plasma Lysine, Methionine and Threonine accumulation; Dietary isoleucine deficiency will result in plasma methionine and threonine surplus, indicating that in reduced protein diets, if L-Valine, L-isoleucine and L-Arginine were not added, dietary lysine, methionine and threonine cannot be fully utilized by chickens to contribute to muscle growth. In particular, dietary Arginine deficiency resulted in a considerable surplus of threonine, affecting mucus secretion. (Figure 1).

Figure 1. Plasma AA concentrations in response to dietary AA deficiency

2. Optimal SID Lysine (g/kg) to AME (MJ/kg) ratio in reduced protein diets

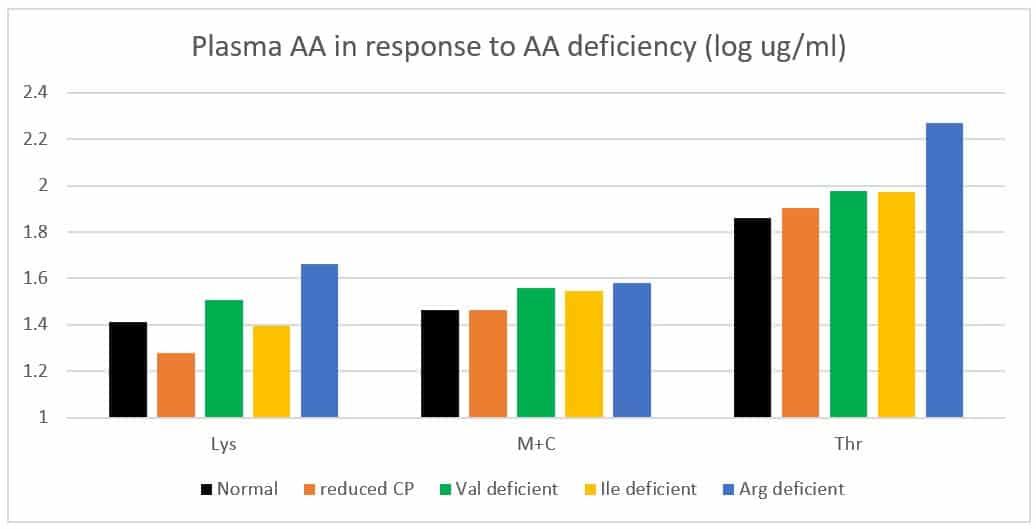

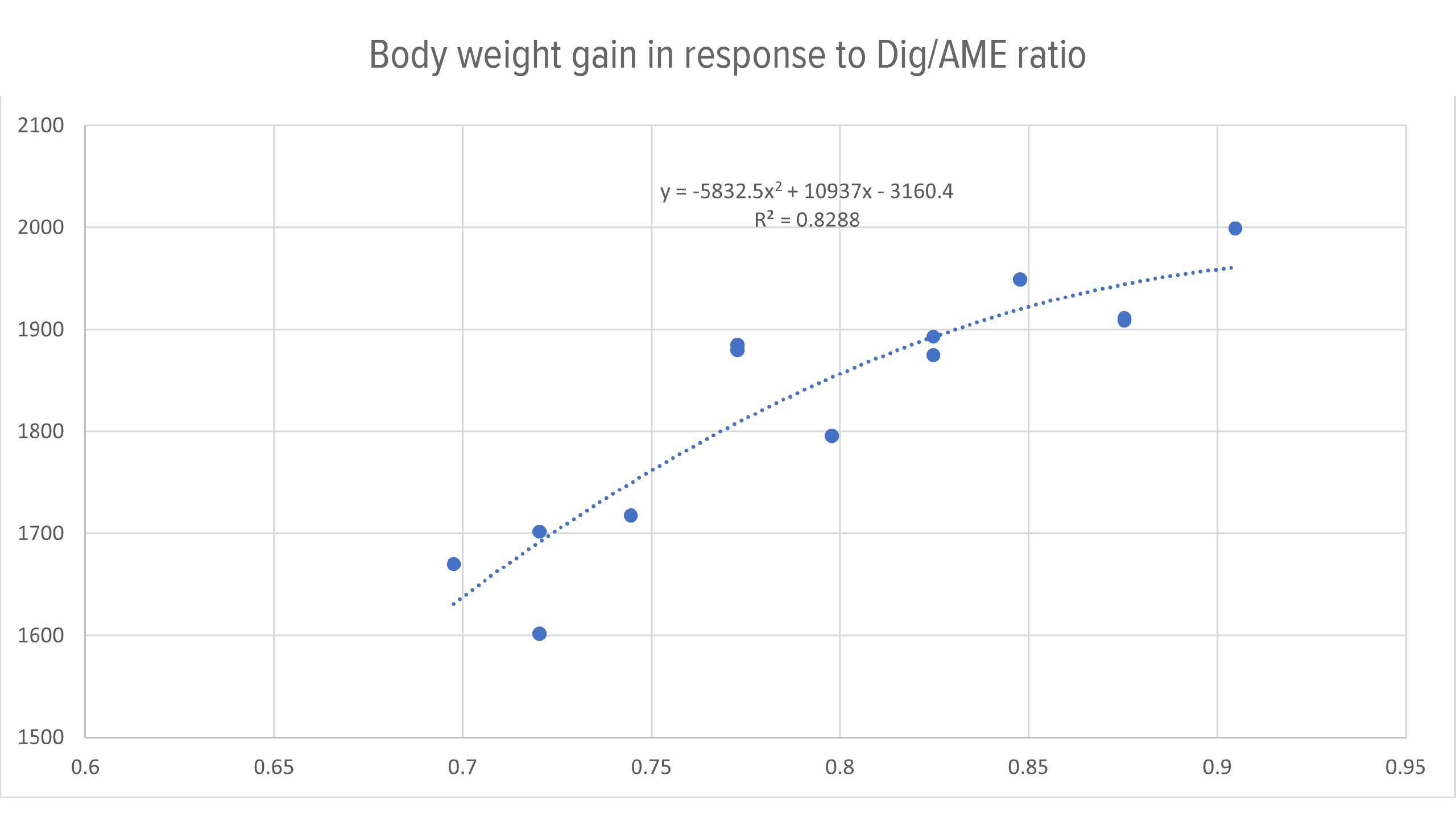

While formulating a reduced protein diet, nutritionists will usually use more grains and reduce oil or fat contents. Considering the higher energy efficiency of oil or fat, it is not clear yet if we need to increase apparent metabolizable energy (AME) requirement in reduced protein diets. However, in 2018, the University of New England (UNE) published a broiler chicken trial paper to show that AME requirement might mainly depend on dietary lysine concentration. In grower period, the optimal SID lysine (g/kg) to AME (MJ/kg) was determined to be 0.88 (Figure 2).

Figure 2 Body weight gain in response to SID Lys/AME ratio on 14-35 days

3. Endogenous loss of taurine in reduced protein diets

It is noticed that in reduced protein diets, more starch will replace fat as the dietary non-protein energy source, leading to more faecal bile acids loss. Recently, the research in Massey University demonstrated that the major endogenous amino acid loss in broiler chicken bile would be taurine. Considering taurine is an important anti-oxidant to regulate immune system health, in stress situation, the reduced protein diet might result in disease infection. It is widely known that taurine is produced by cysteine in chicken body and dietary methionine can convert to cysteine. In a recent broiler chicken trial conducted in the University of Sydney, adding exogenous bile acids to the reduced protein diets significantly reduced mortality rate due probably to increased plasma methionine concentration (Figure 3).

Figure 3. Plasma methionine concentration in response to bile acids addition

4. Reduced protein diets by exogenous protease supplements

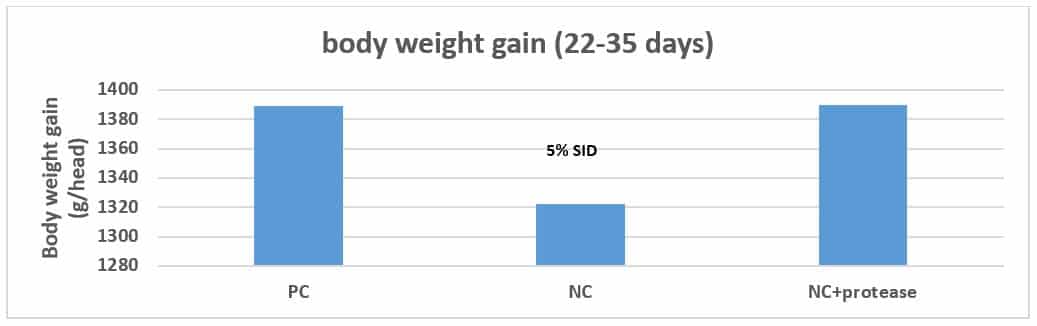

To some degree, in reduced protein diets, dietary protein levels are determined by dietary standard ileal digestible (SID) lysine concentrations because other SID essential amino acids to SID lysine ratios are used in ideal amino acids profile. It is estimated that 5% SID lysine reduction will reduce dietary crude protein by 1% unit. In practice, the efficacy of protease is mainly determined by undigested protein concentration in feed ingredients. Usually when SID lysine (%) to undigested protein (%) ratio is lower than 0.3, dietary SID lysine and other essential amino acids could be reduced by 5% (Figure 4).

Figure 4. Bodyweight gain in male Ross 308 broilers from 22-35 days post-hatch (P = 0.061).

5. Phosphorus and phytase in reduced protein diets

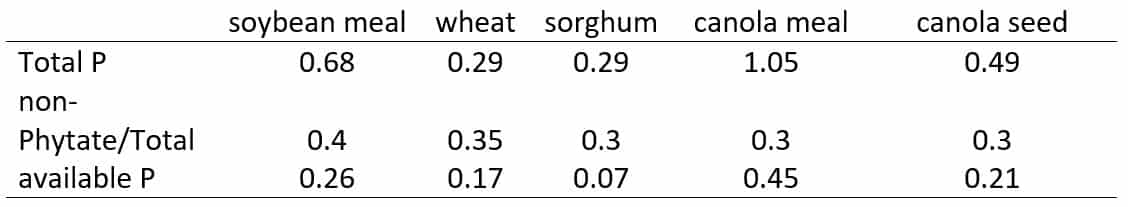

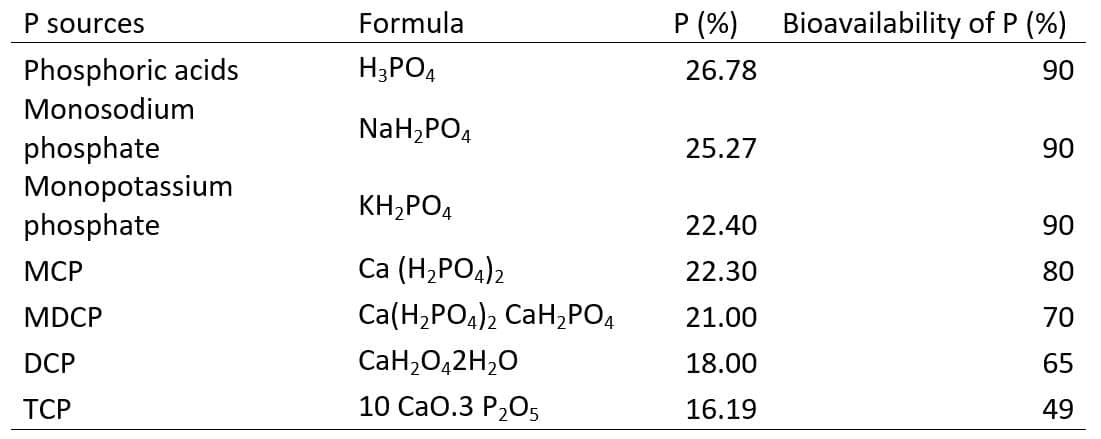

In reduced protein diets, soybean meal and other protein ingredients will be partially replaced by grains and crystalline amino acids. Phytate phosphorus and available phosphorus variation in feed ingredients (Table 1) may increase inorganic phosphorus usage. We also need to reconsider phosphorus matrix value in phytase and absorption rate in inorganic phosphorus (Table 2). In table 1, it is clearly show that in sorghum-based diets, the matrix value of phosphorus in phytase may be higher than that in wheat-based diets, but it will be lower in reduced protein diets because of lower inclusion levels of soybean meal. In table 2, it is shown that when formulating reduced protein diets, both inorganic phosphorus contents and their bioavailability should be considered. In general, inorganic phosphorus bioavailability is strongly related to citric acid solubility and current DCP and MDCP practical bioavailability could be predicted by citric acid solubility.

Table 1. Total P and available P in feed ingredients (%)

Table 2. Phosphorus bioavailability from different sources

6. Nucleotide supplements in reduced protein diets

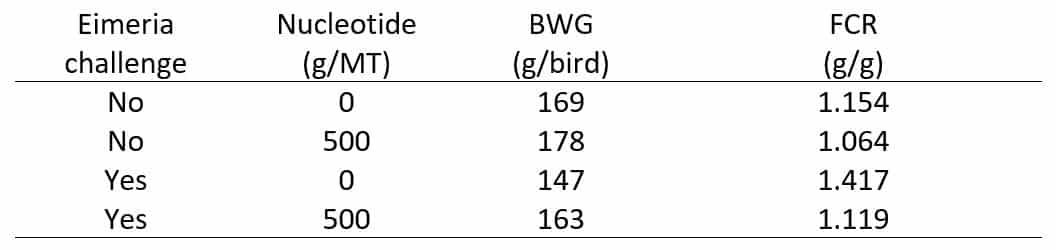

In reduced protein diets, almost all essential amino acids requirements could be met by adding crystalline amino acids. The reduced protein contents mainly come from non-essential amino acids concentration including glutamine and aspartic acids, which are precursors to produce nucleotides in the chicken body. In cocci vaccination and high-stock density stress situation, this exogenous production of nucleotides might not be sufficient to support a healthy immune system. Table 3 clearly shows that in Eimeria challenging situation, adding Nucleotides (IMP) significantly alleviate the challenging impact on chicken body weight gain (BWG) and feed conversion ratio (FCR)

Table 3. Effect of Nucleotides on chicken performance at d 11-15 after challenging

7. Gut health concern in reduced protein diets

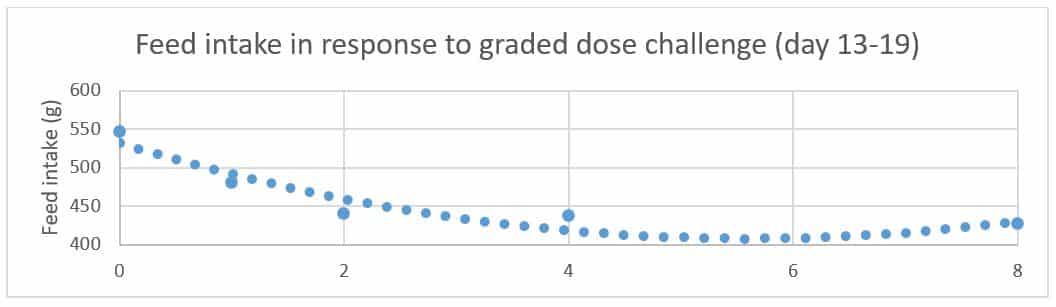

In Australia and USA, coccidiostats are considered as antibiotics and are banned in antibiotics free production. Currently in breeder and claimed antibiotics free chicken production, Eimeria vaccination has been widely practiced controlling cocci infection. However, broiler chicken feed intake is sufficiently reduced by the vaccination challenging dose and each double dose will worsen FCR by 9 points (Figure 5). Some new gut health related feed additives are necessary in reduced protein diets for young animals to fight against disease challenging.

Figure 5. Feed intake in response to graded dose Eimeria vaccination challenging

- Mannanase: Β-Mannan in soybean meal is one of the main antinational factors to decrease the efficiency of nutrient use. Supplementation of the exogenous mannanase has been demonstrated to increase chicken feed intake, significantly reduce coccidial lesion sores and increase breast production. Dietary AME can be saved by 50 kcal/kg due to reduced immune response sensitivity. The efficacy of Mannanase addition is strongly related to soybean meal inclusion levels and optimal crude fiber (%) to SID Lysine ratio is about 1.45 for Mannase response.

- Glucose oxidase: Cell-mediated immunity is thought to be important in the resistance of chickens to infection by coccidia. It has been demonstrated that sporozoites of Eimeria tenella are very sensitive to superoxide ions. Adding exogenous glucose oxidase to reduced protein diets could consume surplus oxygen and increase the shelf life of diets. More importantly, it can endogenously produce hydrogen peroxide to directly kill Eimeria and improve gut health. The heat tolerable glucose oxidase is commercially available now.

- Antimicrobial peptide: Previously it targets Gram negative bacteria such as E coli and Salmonella. Right now, new product is available to protect from Gram positive and negative bacteria infection including colostrum perfringens. Usually, Gram positive bacteria are acids resistance and organic acids are useless in Gram positive bacterial infection.

- Postbiotics: different from traditional probiotics, this postbiotics also includes metabolites from probiotics such as peptides, lipoprotein and bacteriocins, more widely building up the first defense line

- Tri-butyrin: it will promote the overall gut health by facilitating tight junction assembly.

8. Other concerns regarding to reduced protein diets

In reduced protein diets, feed grains such as wheat inclusions will usually increase at the expense of soybean meal. The current supplemental dosage of xylanase needs to be increased to completely degrade soluble Xylan in wheat and reduced viscosity.

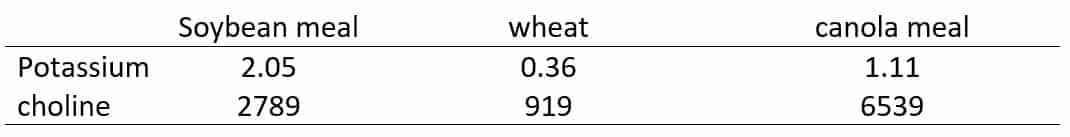

In addition, compared with wheat, soybean meal contains more potassium and choline (Table 4). Therefore, extra potassium bicarbonate or potassium chloride and choline chloride may be increased in reduced protein diets.

Table 4. Potassium and choline concentration in feed ingredients (%)

A study compiled by Redox Animal Nutritionists.

Not long after, French chemist Nicolas Leblanc produced sodium carbonate in 1791; pharmacist Valentin Rose the Younger discovered Sodium Bicarbonate in 1801. Neither Leblanc nor Younger could have imagined their discoveries’ impact on future generations.

How is it made, or where do we find it?

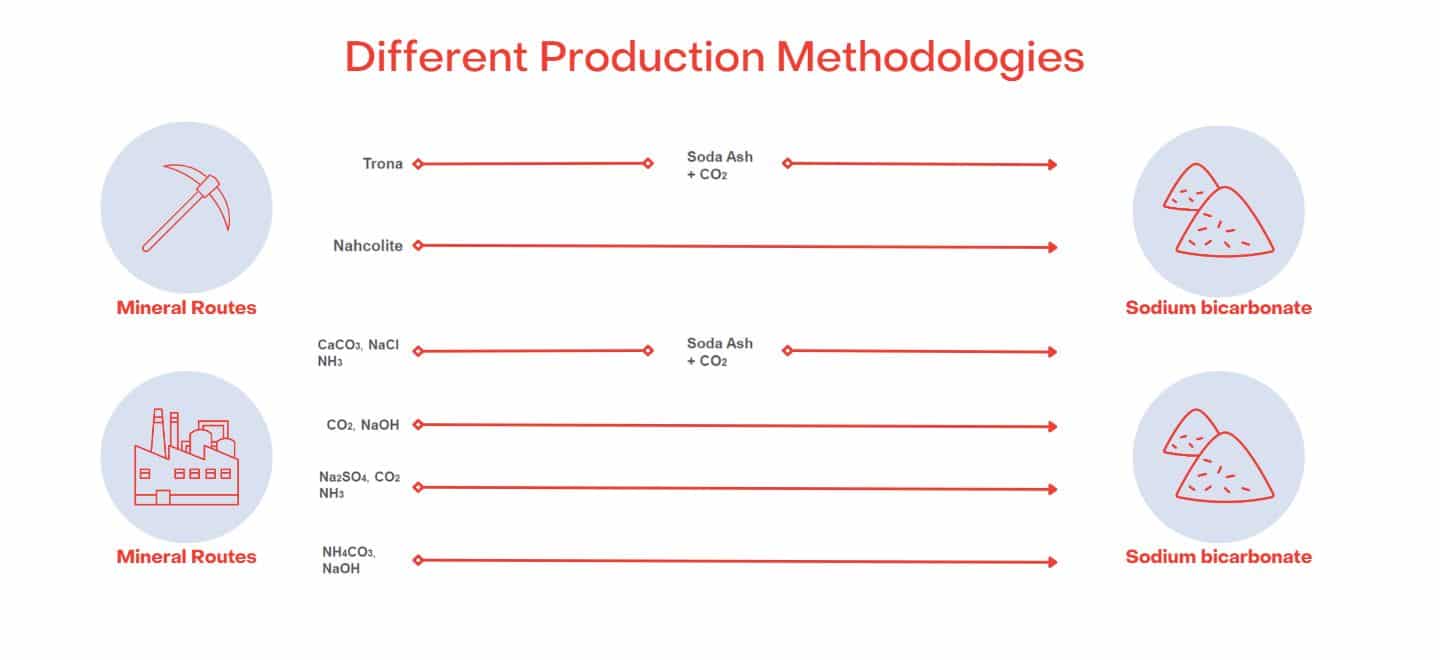

Sodium Bicarbonate is generally synthetically manufactured using the Solvay or the Trona Process.

The Solvay process is an industrial method used to produce Sodium Bicarbonate, commonly known as baking soda. The Solvay process is the reaction of Sodium Chloride, ammonia, and carbon dioxide in water.

Alternatively, the Trona process converts naturally formed/mined soda ash into bicarb.

However, it can also be found naturally occurring in evaporated lake basins worldwide. The largest commercially viable source is Natural Soda in Colorado, USA, which has full organic certification.

Different uses of Sodium Bicarbonate in the food & beverage industry

The flexibility of Sodium Bicarbonate is an undeniable asset for many industries, none more so than the food and beverage industry.

In baked goods, it acts as a leavening agent that produces carbon dioxide when combined with an acidic ingredient such as vinegar or lemon juice. This causes the dough to rise, creating lighter and fluffier baked goods like cakes and muffins. Not only that, Sodium Bicarbonate can also be used to make carbonated beverages like sodas and sparkling waters by dissolving it into water.

The dissolved sodium bicarbonate can then be added to other ingredients like flavourings, syrups, and colourings to create a refreshingly fizzy drink.

Lastly, Sodium Bicarbonate can also be used to tenderise meats for marinades or sauces, as its alkaline nature helps break down tough fibres in the meat’s muscles.

Sodium Bicarbonate or bicarbonate of soda, is a popular baking ingredient. It gives foods like bread, cakes, muffins, and cookies a light, fluffy texture.

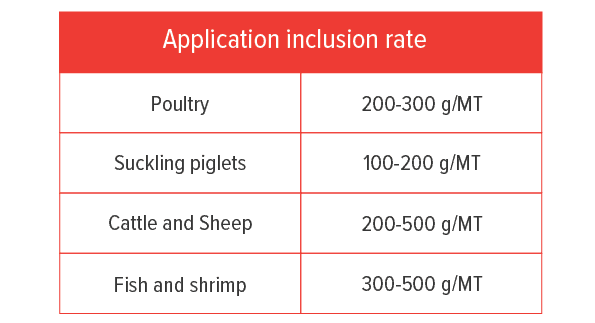

Sodium Bicarbonate’s application in animal feed

Sodium bicarbonate is a vital ingredient in animal feed due to its numerous benefits.

It serves as an excellent source of electrolytes essential for healthy bodily functions. It also helps to maintain proper pH levels in the body, which improves digestion and increases nutrient uptake.

In addition, Sodium Bicarbonate can help reduce the build-up of lactic acid in the muscles, allowing animals to perform better during strenuous activity. Besides that, it can also act as a buffer against digestive upsets such as acidosis and scours and protect against microbial toxins.

All these benefits make Sodium Bicarbonate an essential ingredient in animal feed for optimum health and performance.

But its utility goes beyond the Food and Feed industries. For example:

- It’s commonly used in water treatment and swimming pools for pH adjustment.

- Being an alkali, it assists in removing stains in cleaning and is used in laundry and dish detergents.

- Bicarb is hygroscopic, meaning it absorbs moisture and hence odours.

- Finely powdered bicarb is injected into industrial exhaust stacks to de-sulphurise flue gas before it can escape into the atmosphere.

- Mix it with a bit of water to make a paste, and it relieves insect bites on your skin.

- Calms indigestion and heartburn.

- It’s the abrasive in toothpaste (also helps to remove odours in your breath).

How can we help you?

In 2022, despite the unprecedented supply chain hurdles of a global pandemic, Redox successfully distributed Sodium Bicarbonate across Australia and New Zealand to meet growing demands in both countries and Malaysia.

Redox’s Sodium Bicarbonate is available in various packing sizes, including 25kg bags and bulker bags, coming in a range of food, feed and industrial grades and conforming to FAMI-QS and Food Safety Regulation.

Contact one of our experts to discover how Redox can be essential to your sourcing strategy.

In September of this year, Redox achieved certification with FAMI-QS after being certified by DNV Business Assurance Australia Pty Limited.

What is FAMI-QS?

The ultimate goal of this Code of Practice is to ensure feed safety by minimising unsafe practices and the risk of hazardous ingredients entering the food chain. Animal feed is considered unsafe for its intended use if it is likely to pose a risk to (has adverse effect on) human or animal health, or if the food derived from food-producing animals is unsafe for human consumption.

The FAMI-QS code of practice provides requirements for implementing measures necessary to ensure animal feed safety and quality of products manufactured by processes, as defined by FAMI-QS. The code covers requirements on good manufacturing practices, on the HACCP programme and suggestions on continuous improvements to the design, management of operations and risks with a goal of maintaining feed safety and quality.

The scope of FAMI-QS is specialty feed ingredients. A specialty feed ingredient is defined as any intentionally added ingredient, not normally consumed as feed by itself, whether or not it has nutritional value, which affects the characteristics of feed or animals/animal products and animal performance.

The Feed Chain Activities covered by FAMI-QS are Production – The processes and methods used to transform tangible inputs (raw materials, semi-finished goods) and intangible inputs (information, data) into goods and Trade – The action of buying, handling, storage, transporting and selling goods and services.

For more information on production processes covered by FAMI-QS certification, please read more here.

Could reduced crude protein (CP) diets reduce NH3 emission by 25% in chicken or pig farms? In today’s Animal Nutrition Insights, Redox’s Animal Nutritionist Dr Yumin Bao shares his research on amino acids and feed enzymes supplementation that could help to reduce the environmental impacts of poultry and pig production.

Poultry and swine farming has a significant environmental impact on climate change and air or water pollution. In the past decade, phytase, a feed grade enzyme, has been widely used in poultry and swine production to reduce inorganic phosphorus usage and pollution significantly.

In recent years, the poultry and pig industry has successfully developed reduced crude protein (CP) diets by supplementing unbound crystalline L-Lysine, L-Methionine, L-Threonine, L-tryptophan, L-Valine, L-Isoleucine and L-Arginine, but not compromising chicken and pig performance. It is estimated that each 10 g/kg CP reduction in pig farms could reduce NH3 by 10%, and in poultry, each 15 g/kg CP reduction might reduce NH3 by 16% (Cappelaere et al., 2021).

Based on recent broiler chicken studies at the University of Sydney, apart from L-Lysine, L-Methionine and Threonine, L-Valine, L-Isoleucine, and L-Arginine are added to broiler chicken diets could further reduce CP by 15g/kg.

However, it is noticed that in the current CP reduction strategy, feed formulation was conducted by digestible lysine concentration and then balanced with other digestible amino acids, and undigested CP was not considered in the feed formulation.

It is well-known that adding exogenous feed enzymes in poultry and swine diets could overcome the adverse effects of antinutritional factors and improve the digestion of dietary nutrients.

While Xylanase is becoming a norm in Australian wheat-based diets to reduce digesta viscosity in chicken or pig gut, adding Protease and Mannase has recently been demonstrated to improve dietary amino acids digestibility by 3% and increase chicken body weight gain by 5%, respectively.

Body weight gain in response to Dig AME ratio

Therefore, under the current commercial conditions, adding protease and mannase could reduce Digestible Lysine concentration from 1.1% to 1.0% in the finisher period, roughly another 10-15 g/kg CP reduction.

In conclusion, in the current poultry and swine diets with supplementation of L-Lysine, L-methionine and L-Threonine, further adding L-Valine, L-isoleucine, L-Arginine, protease, and mannase could reduce at least 25 g/kg CP and accordingly reducing NH3 emission by 25% in chicken or pig farms.

Contact us today and ask us how we can assist with specialist advice from one of our nutritionists and offer the best price and service on any of the below products:

- L-Lysine, L-Methionine,

- L-Threonine,

- L-tryptophan,

- L-Valine,

- L-Isoleucine,

- L-Arginine,

- Xylanase,

- Protease,

- Mannase

Magnesium sulphate, often known as Epsom salt, is a versatile chemical utilised in various markets. With its long history, its use cases are as extensive as they are varied.

In 1618, a villager named Henry Wicker at Epsom in England tried to provide his cattle water from a well. They refused to drink it because of the bitter flavour of the water. However, the farmer discovered that the water healed wounds and rashes. The fame of Epsom salts grew over time.

Eventually, it was recognised to be magnesium sulphate, MgSO4.

How is magnesium sulphate used?

Primarily used as a foliar and irrigated fertiliser in the agriculture sector where it improves soil fertility, creating an environment conducive to growth.

Another industry it is commonly used in is the animal nutrition industry, where it is used in animal feed (feed grade) to aid the metabolism of carbohydrates, lipids (fats) and proteins and for nerve activity and muscle contraction.

More recently, magnesium sulphate has experienced increased use in the pharmaceutical and health sectors with applications such as bath salts and isolation tanks.

It is even used as an active ingredient in pain-relieving lotions, creams and oils within the personal care industry.

Yet, there are instances of it being used in sectors as diverse as:

- Food preparation where Magnesium sulphate is used as a brewing salt in beer production and is used as a coagulant for making tofu.

- Construction, where it can be found being used to prepare specific types of cement by the reaction between magnesium oxide and magnesium sulphate solution.

Magnesium Sulphate is primarily used as a foliar and irrigated fertiliser in the agriculture sector where it improves soil fertility, creating an environment conducive to growth.

The Redox advantage

Redox’s magnesium sulphate is available in various packing sizes, including 25kg bags and bulker bags, coming in a range of forms (heptahydrate, anhydrous, trihydrate, monohydrate) and conforming to many monographs (FCC, BP/USP, OMRI)

At Redox, we take the time to understand our markets and employ a team of skilled specialists to help guide and advise our clients. Our scale efficiency allows us to keep expenses low. At the same time, our broad selection provides clients with a “one-stop-shop” alternative for services in many sectors.

Contact one of our experts to discover how Redox can be an essential element of your sourcing strategy.

Lysine was first isolated from milk protein by the German biological chemist Ferdinand Drechsel in 1889 and subsequently manufactured by German chemists Emil Fischer and Fritz Weigert some 12 years later.

It was a significant advancement since, unlike other amino acids, the human body cannot produce Lysine and therefore must be ingested via food. Meat, fish, dairy, eggs, and some plants such as soy are all excellent sources.

Plant-based diets generally contain low levels of Lysine, methionine, threonine, and other essential amino acids. Adding feed grade amino acids to diets can significantly improve animal performance and development.

Amino Acids in Animal Nutrition

Lysine is used across various industries, including pharmaceuticals, nutritional supplements, and the cosmetics sectors; however, it is also an essential dietary supplement widely utilised to feed poultry, pigs, and other livestock.

Farm animals, in particular, chickens and pigs, are usually fed plant-based diets that generally contain low levels of Lysine, methionine, threonine, and other essential amino acids.

Deficiencies of these amino acids impede animal performance and development while impairing immunological function. As a result, in the 1960s, crystalline L-Lysine HCL crystals were produced commercially and made available for piglet diets to correct this issue.

Lysine is the most abundant essential amino acid in pigs’ and chickens’ skeletal muscle protein. Deficiencies in Lysine will limit muscle growth and divert Lysine away from immunological purposes, increasing mortality.

In typical wheat-barley-soybean based diets, Lysine is the first limiting amino acid for pigs and the second limiting amino acid for chickens. Any gap between the dietary lysine concentration and animal requirements needs to be fulfilled by adding crystalline L-Lysine or more soybean meal.

Adding more soybean meal will raise feed costs and other amino acid concentrations, resulting in protein loss as waste.

Lysine in the Market

Although currently it is produced from a corn starch base, genetic engineering research is actively pursuing bacterial strains to improve production efficiency and allow it to be made from other substrates.

Lysine fermentation by Corynebacterium glutamicum was developed in 1958 by Kyowa Hakko Kogyo Co. Ltd. and is the second oldest amino acid fermentation process after glutamate fermentation. The fundamental mechanism of lysine production, discovered in the early stages of the process’s history, gave birth to the concept known as “metabolic regulatory fermentation,” which is now widely applied to metabolite production.

BESTAMINO L-lysine is produced by the advanced fermentation process using raw materials such as corn and sugar cane, thus combining sustainability and efficiency in animal nutrition.

Lysine production for animal feed is a primary global industry; according to Trygve Brautaset, who published his findings in All About Feed in 2010, Lysine output for animal feed is approximately 700,000 tons and has an estimated market value of over €1.22 billion.

By 2020 Lysine fermentation production was estimated to underpin a demand of more than 2.5 million metric tons per year.

We can help

Working with a reliable supplier is essential. Our exclusive partnership with Cheil Jedang Bio gives Redox exclusive access to Bestamino Lysine via their manufacturing facilities located across the world in China, Indonesia, Brazil, and the United States. We currently stock and supply our customers within Australia and New Zealand and are well-positioned to meet and exceed your needs.

To assure our customers get the best products at the best price, we can source Lysine in a variety of packing sizes across the entire range of L-Form Amino Acids, including:

- L-lysine

- L-methionine

- L-tryptophan

- L-threonine

- L-valine

- L-arginine

- L-arginine

- L-histidine

- L-isoleucine

Contact one of our industry specialists today and ask us what we can do for you for the best price and service on Lysine.

There is considerable interest in the development of reduced protein diets balanced with supplemental crystalline amino acids for broiler chickens due to economic, environmental and bird welfare advantages (Moss et al., 2018).

However, reduced protein diets may result in dietary amino acids being redistributed away from growth and production processes, toward intestinal cells involved in immune and inflammatory responses (Le Floc’h etal., 2004). In addition, an unbalanced supply of amino acids (AA) in the diet can be deleterious to the immune system (Li et al., 2007).

Thus, an ideal balance of AA is crucial for broiler chicken production in particular if birds are reared without antibiotics. All of the crystalline AA supplemented in commercial poultry production are in their natural form (L-form) except methionine (Met) (Esteve-Garcia and Khan, 2018). In poultry diets, Met is the first limiting amino acid and the dietary supplemental Met sources include L-Methionine (L-Met; 99% purity), its synthetic forms DL-methionine (DL-Met, 99% purity) and liquid DL-2-hytroxy-4-methylthio butanoic acid (DL-HMTBA, containing 88% of active substance).

All three sources of methionine are currently supplemented in poultry diets to meet birds total sulfur amino acids (TSAA) requirements.

Met Metabolism and Function

Met is an essential AA involved in multiple fundamental biological processes, including protein synthesis, transmethylation and the synthesis of homocysteine. Apart from protein synthesis, Met is the major donor of the methyl group to affect DNA and protein methylation in cells including creatine production (Wu, 2013).

High dietary arginine has been recently demonstrated to improve chicken gut health (Bao, 2019) and creatine concentration in chicken breast meat (Chamruspollert et al, 2002) but possible depressed chicken performance might be due to increased dietary Met requirement (Chamruspollert et al., 2002).

Homocysteine is a key substrates in three additional essential reactions: (1) the recycling of intracellular folic acids;(2) the catabolism of choline and betaine; and (3) the transsulfuration pathways to produce cysteine (Cys) (Finkelstein, 1998).Consequently, the minimal daily requirement for Met varies as a function of the availability of cysteine, choline or betaine, Vitamin B12 and folic acid but cannot be replaced by choline or betaine in producing immune responses.

Because a portion of dietary Met is normally converted to Cys, it suggests that dietary Cys can spare, reduce, or replace a portion of the requirement for Met by as much as 50%-80% in birds (Shoveller et al., 2005). However, The Met portion used for Cys biosynthesis is only 81% on a dietary concentration basis, indicating the magnitude of response to Met supplementation when Cys is also deficient is less than that when Met is singly deficient (Baker, 2009).

Cys is the precursor of glutathione (GSH) and hydrogen sulfide (H₂S) (a signalling molecule) in animal cells, positively correlated with glutathione concentrations in the liver, spleen and muscle, playing an important role in regulating cellular signalling pathways in response to immunological challenges (Li et al., 2007). Cys preferably participates in the synthesis of keratin in feathers comparing to nutrient deposition in the breast muscle (Bonato, 2011). Glutathione is essential for normal intestinal function and the deficiency of glutathione will increase the susceptibility to carcinogenesis, oxidative injury.

It is noteworthy that taurine is an end product of TSAA with various physiological roles including conjugation with bile acids, stabilization of the cellular plasma membrane and a major antioxidant to regulate the cellular redox state (Hagiware et al., 2014). However, in some circumstances, taurine cannot be sufficiently synthesized in the liver although plasma Met and Cys concentrations are high. Recently it was found that supplementation of branched chain amino acids (BCAA) may improve taurine biosynthesis in the liver. Thus, the higher dietary BCAA levels may help TSAA to fully play their functional roles.

Commercially available L-Met is produced by bacteria fermentation and can be directly used to synthesize protein, provide methyl group or degrade through pathways to produce Cys. For DL-Met, it contains 50% D-Met and 50% LMet. In the chicken body, its D-Met is oxidatively deaminated to the α-keto analogue of L-Met, 2-keto-4 methylthio butanoic acid (KMB) by D-amino acid oxidase. It is assumed to be 100% efficacy, but it has been traditionally accepted that DL-Met is 95% efficacy relative to L_met due to equal dietary contributions of the D-and L-isomers (Baker, 2006).

Then KMB is converted to L-Met by transaminase (Brachet and Puigserver, 1992). For DL-HMTBA, it contains 50% L-HMTBA and 50% D-HMTBA. Its D-HMTBA is oxidized to KMB by L-2-hydroxy acid oxidase and D-HMTBA is dehydronised to KMB by D-2-hydroxy acid dehydrogenase. Then KMB is converted to L-Met by transaminase (Dibner and Knight, 1984). The key enzyme, D-amino acid oxidase exists only in the liver or the kidney and D-Met is not utilized directly by the cells of the gastrointestinal tract (Shen et al., 2015).

Relative Bioavailability Values of Met From Different Sources.

The evaluation of relative bioavailability values (RBV) of Met sources in broiler chickens has remained controversy for more than 50 years differences in experimental designs, methionine requirements, supplemental methionine levels, dietary factors such as dietary lysine, arginine, cysteine and branched chain amino acids concentrations, dietary energy levels, response criteria, the age of broiler chickens and statistical models. Based on a dose-response trial, the slope-ratio and non-linear multiple regression models have been widely used in those RBV evaluation studies (Little et al., 1997).

For three sources of Met, in the slope-ratio multiple regression model, the following multilinear regression was applied:

Y = a + (b1X1 + b2X2 + b3X3)

In which y = growth performance ( body weight gain and FCR, a = intercept (growth performance achieved with the negative control), b1 =the slope of DL-Met line, b2 =the slope of L-Met line and b3 =the slope of liquid HMTBA line, X1 = intake of supplemental DL-Met (g/day/bird), X2 = intake of supplemental L-Met (g/day/bird) and X3 = intake of supplemental liquid HMTBA (g/day/bird). RBV of L-Met and liquid HMTBA to DL-Met were given by the ratio of slope coefficients, b2 : b1 and b3 : b1 , respectively.

For three sources of Met, in the non-linear multiple regression model with common plateau, the following non-linear regression was applied:

Y = a + b (1 ̶ e(c1X1 + c2X2 + c3X3))

In which y = growth performance ( body weight gain and FCR), a = intercept (growth performance achieved with the negative control), a + b = asymtote, c1 =the steepness coefficient for DL-Met , c2 =the steepness coefficient for L-Met and c3 =the steepness coeficient of liquid MHA line, X1 = intake of supplemental DL-Met (g/day/bird), X2 = intake of supplemental L-Met (g/day/bird) and X3 = intake of supplemental liquid HMTBA (g/day/bird). RBV of L-Met and liquid HMTBA to DL-Met were given by the ratio of steepness coefficients, c2 : c1 and c3 : c1 , respectively.

Based on the slope-ratio analysis, in broiler chickens (21 to 42 d ) exposed heat stress, the RBV of liquid HMTBA ranged from 67% (FCR) to 83% (weight gain) relative to DL-Met (Rostagno and Barbosa, 1995). Following the non-linear regression model, Lemme et al., (2002) reported 72% weight gain and 51% FCR (1 to 42 days) of liquid DL-HMTBA RBV compared to DL-Met.

However, based on predominantly not accessible or published data in non-peer-reviewed journals, Vázquez-Añón et al., (2006) argued that DL-Met and DL-HMTBA did not fit the same dose response profile, concluding that at lower or deficient dietary TSAA levels, DL-HMTBIA responses were lower than those of DL-Met, whereas at the commercial or above requiremental levels, DL-HMTBA outperformed those for DL-Met.

In these studies, the highest supplemental level of Met was 0.4%. On the basis of 1.13% and 1.02% digestible lysine in the starter (d1-d10) and grower (d 11-d 28) periods, respectively, an experiment was conducted to consist of a basal diet without Met addition, and 4 increasing Met doses for DL-HMBTA and DLMet resulting in TSAA/Lysine ratios from 0.62 to 0.73 in the starter phase and 0.59 to 0.82 in the grower phase. For the starter period, growth performance were not improved from 0.66 to 0.73 TSAA/Lysine ratio. For the grower period, performance parameters responded quadratically to either DL-Met or DL-HMTBA supplementation, showing better efficacy for HMTBA than DL-Met at higher TSAA levels (Agostini et al., 2016).

In this study, although separate plateau models were used as suggested by Kratzer and Little (2006), Hoehler (2006) insisted that it was correct to use either slope-ratio (linear response) or nonlinear models with common plateau depending on the data structure of the respective dose-response trial.

Based on a control diet containing digestible TSAA 0.56%, adding 0.095%, 0.190% and 0.285% of either L-Met or DL-Met resulted in TSAA/Lysine ratios from 0.44 to 0.67 (Shen et al., 2015). In this study, experimental data (1 to 21 d) were analysed by the slope-ratio multiple regression model. The RBV of L-Met ranged from 138% (weight gain) to 141% (FCR) relative to DL-Met. Surprisingly, adding 0.190% L-Met to the control diet (TSAA/Lysine ratio is 0.59) had reached the growth plateau and it was much lower than 0.78 suggested by Dozier and Mercier (2013). In this control diet, digestible Threonine/Lysine ,Isoleucine/Lysine and digestible Valine/Lysine is 0.63, 0.63 and 0.71, respectively. They were also much lower than Ross nutrient recommendation. Considering that maximal chicken body weight gain at 21 days of age was only 762 grams , other dietary factors might limit Met supplementation responses.

In a 37 days broiler chicken trial, on the basis of control diets containing digestible TSAA 0.54%, 0.52% and 0.50% in starter, grower and finisher periods, respectively, adding 0.05%, 0.10%, 0.15% and 0.20% of either L-Met or DL-Met resulted in TSAA/Lysine ratios from 0.44 to 0.61in starter period, 0.50 to 0.69 in grower period and 0.51 to 0.71 in finisher period, respectively (Esteve-Garcia and Khan, 2018). In this study, when experimental data in 37 days were analyzed by non-linear models with common plateau, the RBV of L-Met ranged from 112% (weight gain) to 130% (FCR) relative to DL-Met.

Interestingly, for broiler chickens fed purified diets, L-Met was more efficiently utilized than DL-Met and DL-Met in turn was superior to equimolar amounts of DL-HMTBA. However, in semi-purified diets continuing high proportion of natural L-Met provided by soy bean meal, this trend lost sensitivity (Smith, 1965). It is noticed that in this semi-purified, soybean meal provided 75% of dietary total methionine concentration, leaving a very small proportion of the methionine requirements to be provided by supplemental methionine sources.

Therefore, the higher dietary supplemental methionine levels or the control diet containing much lower natural L-Methionine are crucial for methionine RBV evaluation. Recently a dose-response trial was conducted in an Australian University to compare RBV of L-Met and DL-HMTBA relative to DL-Met. On the basis of the control diet containing 0.637% digestible TSAA, adding equimolar 0.138%, 0.276% and 0.414% either DL-Met, L-Met or DL-HMTBA led to digestible TSAA/Lysine ratio from 0.50 to 0.80.

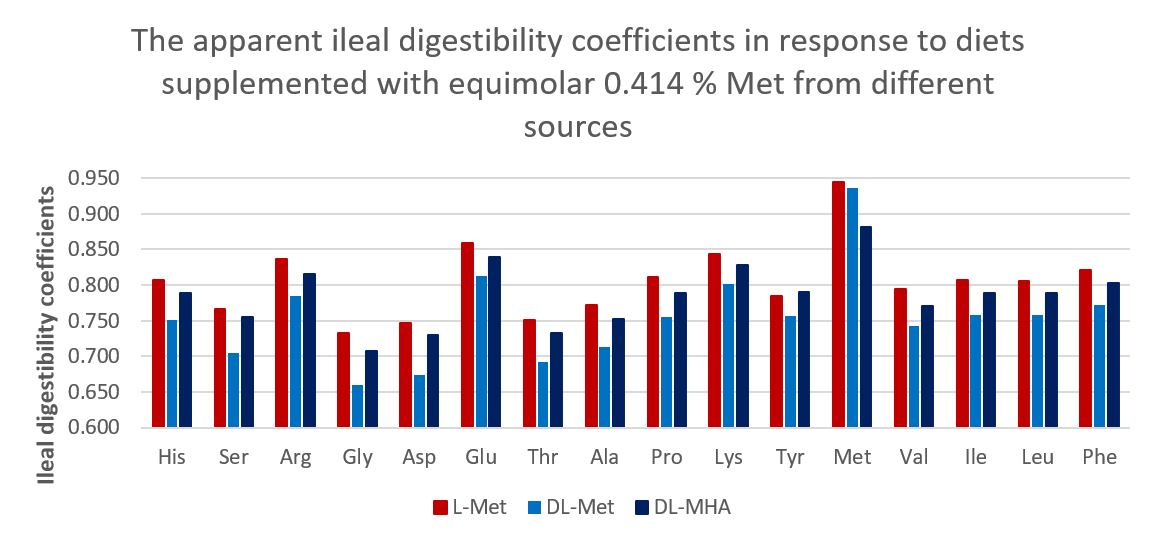

Surprisingly, even adding equimolar 0.414% either DL-Met or DL-HMTBA did not reached the response plateaus. However, for L-Met, when TSAA:Lys ratio equalled to 74.9% and 74.2%, the optimal body weight gain and FCR were reached, respectively, confirming that L-Met has the highest bioavailability. It is noticed that in this trial, the highest supplemental Methionine concentration achieved 56% of the dietary total methionine requirement, resulting in the highest ileal digestibility of Met and other amino acids (Figure 1), indicating that supplementation of l-Methionine significantly reduced N excretion.

It is noteworthy that TSAA: Lys ratio of 74 to 75 is the current practice in broiler chicken production. The fact that supplementation of either DL-Met or DL-MHA did not reach the body weight gain response plateau, strongly suggests in practice, L-Met supplementation may at least improve FCR by two points.

Figure 1. The apparent ileal digestibility coefficients in response to diets supplemented with equimolar 0.414% Met from different sources.

Study compiled by Dr Yumin Bao, Redox Animal Nutritionist.

For comprehensive animal nutrition, it is well known that the use of in-feed antibiotics has until now, been the main strategy for controlling Clostridium perfringens- associated necrotic enteritis in poultry production. Recently, due to the fear of development of antibiotic resistant microbes, there is a strong trend to totally ban the inclusion of non-therapeutic antibiotics in poultry and swine feed.

Although various alternatives to antibiotics including probiotics, organic acids, enzymes, yeast peptide, prebiotics, essential oils and vaccination have been developed, no single satisfactory non-antibiotics measure against C. perfringens has been identified.

Probiotics have been defined as the live microbial feed supplement which beneficially affect the host animal by improving its intestinal balance and overall animal nutrition.

Probiotics where originally derived from lactic acid bacteria (LAB) fermented dairy products and the faecal microbiome. Traditionally probiotics was thought to produce short chain fatty acids, optimise IgA production, modulate homeostatic bile acids production, and increase the integrity of intestinal epithelial layers.

In recent years, new technology and new fermentation method have been developed to select more specific super bacteriostatic strain for the new generation of probiotics (Clostide).

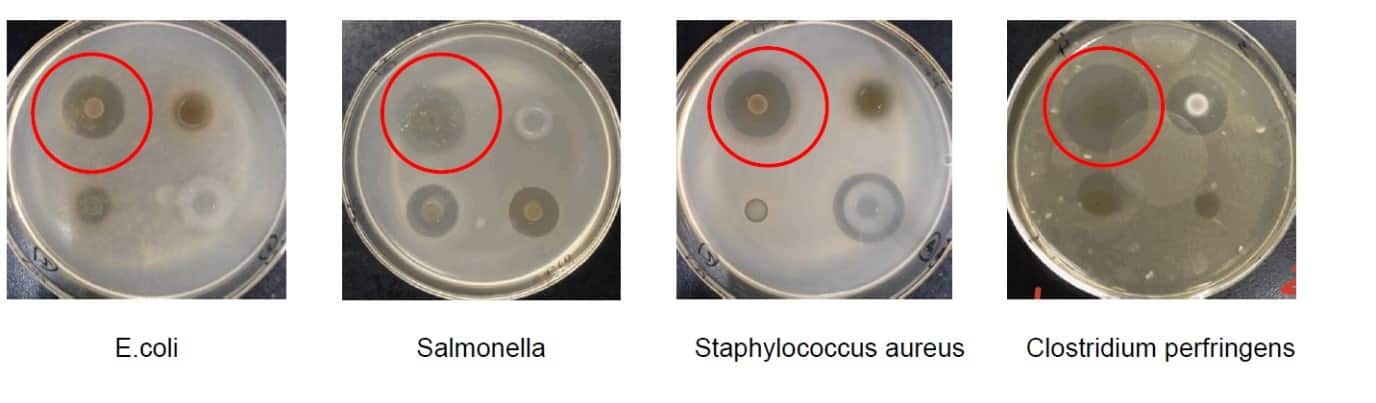

In the Figure 1, it is clearly shown that the antibacterial ability of Bacillus Licheniformis HJ135 developed by Vega group is 20 times than that of normal stain.

Animal nutrition in other animals

- In broiler chickens challenged with perfringens, adding 300 grams/MT Clostide significantly reduced incidence of Necrotic enteritis; FCR was improved by 7 points.

- In laying chicken hens, adding 300 grams/Mt Clostide improved egg production by 4.8% and significantly mortality rate.

- In sows, adding 500 grams/ MT Clostide at 90 days after gestation significantly improved piglet weaning liveability and average daily weight gain was improved by 11.6%.

- For weaned piglets, the addition of 500 grams /MT Clostide increased body weight gain by 4.15%; Diarrhea rate was reduced from 10.65% to 2.65%.

Want to know more? contact one of our industry specialists and ask them today

In today’s Animal Nutrition Insights, Redox’s Animal Nutritionist Dr Yumin Bao shares information on Yeast Peptides and how their inclusion in animal feed can improve several conditions that often affect animal health.

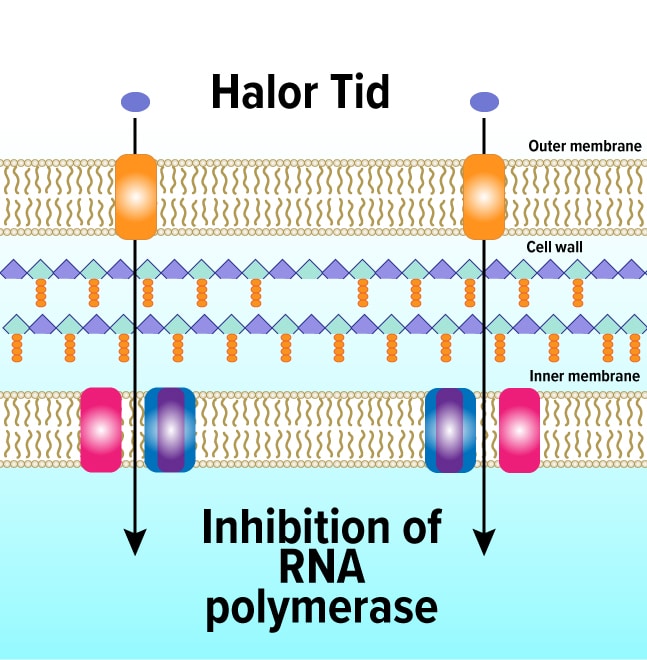

Yeast peptide is a naturally occurring molecule with 19 unique amino acids, long lasso structure antimicrobial peptide from the bacteria Citrobacter braakii.

Usually, this peptide has been referred to as the host defence peptide to directly kill bacteria, yeasts, fungi and virus. Because this peptide exhibits a net positive charge and a high ratio of hydrophobic amino acids, it can selectively bind to negatively charged bacterial membranes and is able to cross the membrane to inhibit RNA synthesis, resulting in lysis of the targeted pathogens such as E.coli and Semolina.

Therefore, different from antibiotics, it is difficult for pathogens to develop the resistance to this peptide since it would require drastic changes in the composition of membranes in targeted bacteria.

It has been demonstrated that the addition of this yeast peptide can improve several conditions in the below animals:

Weaning piglets with an average body weight at 7.98 kg for 28 days –

- significantly reduced diarrhoea incidence from 12.4% to 6.74%

- increase daily body weight gain by 7.1%

- feed conversion ratio by 8%.

Laying hens –

- increased egg production by 3.8%

- significantly reduced broken eggs and mortality rate.

In broiler chickens, compared with the antibiotic treatment, the combination of this yeast peptide and the acidifier significantly reduced the mortality rate and improved body weight gain by 8.4%. As well in ruminants such as lambs, this yeast peptide has the significant effect on the prevention of urethral calculus.

In a field trial study conducted in China, the incidence rate of urethral calculus in three farms were 5.56%, 4.55% and 1.45%, respectively, one week after using the yeast peptide, the incidence of urinary stone dropped to zero due probably to the fact that the yeast peptide reduces pathogens infections.

Want to know more? Contact one of our industry specialists and ask them today.

Our Partnering Manufacturers