Protein supplements are gaining immense popularity worldwide, not just among professional athletes but also among a broader range of consumers who recognize their incredible benefits for sports nutrition, muscle building, and overall health. However, the traditional animal and plant-based protein options have limitations, necessitating the search for innovative alternatives. One such exciting product is yeast protein.

Protein has been shown to have numerous positive effects, including:

- Weight management,

- muscle building,

- tissue recovery,

- strength gains, and

- improved body composition.

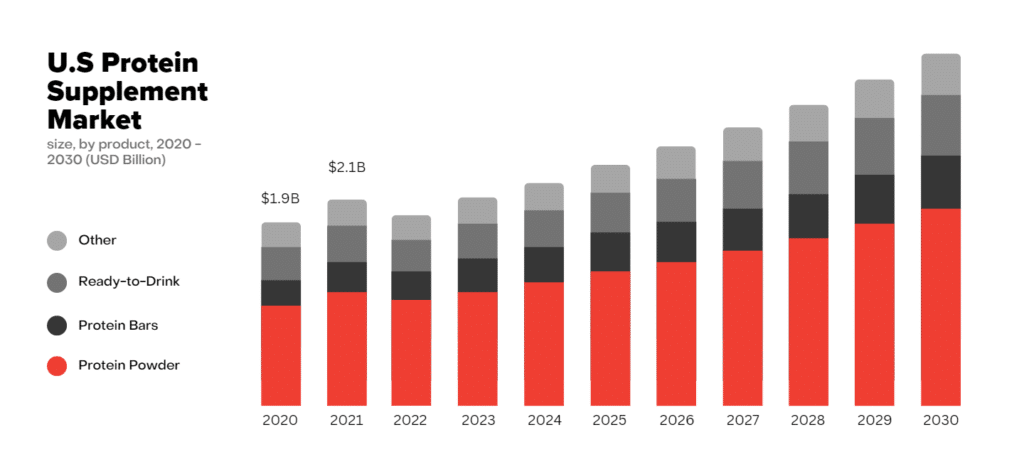

These benefits have propelled the supplement market to a staggering value of $6.3 billion in 2021, with further growth projected in the coming years.

The global protein supplements market was valued at USD 6.26 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 8.0% from 2022 to 2030. The market is gaining momentum owing to the increasing number of health-conscious consumers and fitness centres around the globe.

The need for new protein sources

Our planet is facing a significant challenge in meeting the growing global demand for protein. Over the past two decades, protein consumption has been on the rise, and this trend is expected to continue as the population grows and economies thrive. However, relying solely on traditional animal agriculture to meet this demand poses a problem. In light of this concern, both companies and consumers are now turning their attention to yeast protein as a promising and sustainable solution.

Protein supplements come from various sources such as whey, casein, beef, fish, egg, soy, pea, hemp, and rice. Animal proteins, like whey, are often considered superior to plant-based options due to their rich content of essential amino acids. Moreover, plant-based proteins may not be as easily digested in the gut and can negatively affect metabolism and immune response.

Whey protein, derived from milk during cheese production, has long been regarded as the gold standard. It is a complete protein that is quickly digested and contains high levels of branched-chain amino acids (BCAAs) and leucine, which are crucial for muscle growth and recovery.

However, using animal sources in whey protein presents a significant barrier for many consumers. Environmental concerns, animal welfare issues, and contamination fears have prompted a global shift towards reducing animal product consumption. For instance, nearly half of the population in Singapore has already reduced or eliminated animal products from their diets. Similar trends are observed in other Asian countries, where many individuals opt for meat reduction. As a result, there is a growing demand for alternatives.

Challenges with plant-based proteins

Plant-based proteins have gained popularity as an alternative but still have limitations. They often lack the same amino acid content, digestibility, and protein synthesis capacity as animal proteins. Additionally, large-scale cultivation of plant-based protein sources, such as wheat, soy, and peas, requires substantial land resources and can be impacted by weather conditions. Concerns about heavy metals, pesticide residues, and genetically modified organisms further dampen consumer enthusiasm.

The Rise of the Alternative: Yeast Protein

Yeast proteins are an exciting and promising alternative. Nutritional yeast, commonly available in the market, is often known for its immune-boosting and gut health benefits. However, it is also a rich microbial protein source with high BCAA content.

While yeast protein has been studied for its nutritional value in animal agriculture for several decades, research on its impact on humans has been limited.

The properties and composition of AngeoPro

AngeoPro, derived from Saccharomyces cerevisiae, commonly known as brewer’s or baker’s yeast, contains over 70% high-quality protein and has a digestibility value similar to whey protein. It boasts a leucine content comparable to whey protein and even higher levels of total BCAAs. Acting as a “slow protein,” AngeoPro provides a steady and continuous supply of amino acids.

AngeoPro closely resembles animal proteins, outperforming low-quality plant proteins regarding nutritional value. Additionally, AngeoPro, as a fermentation product, offers advantages such as a reliable supply chain and reduced land requirements. The wastewater generated during AngeoPro production is repurposed as organic fertilizer for yeast cultivation, creating a more sustainable production process.

How Can Redox Help?

When it comes to meeting the surging demand for sustainable and high-quality protein, look no further than Redox as your trusted partner.

With yeast protein emerging as a revolutionary solution, Angel Yeast stands at the forefront of research and development, ensuring a future of protein supplementation that resonates with consumer preferences.

Contact us today to explore how Redox can be the essential catalyst in your sourcing strategy, providing you with unmatched expertise and top-notch solutions.

We at Redox are excited to share that we have renewed our Chemical Educational Foundation’s Presidents Club membership. This is our way of supporting the CEF team’s efforts to promote chemistry education and raise awareness among students in grades K-8.

CEF’s You Be The Chemist programs uniquely connect business and education in local communities to reach students early in life and ignite a passion for chemistry and science-related careers.

Companies and individuals in the science and chemistry industries have invested in You Be The Chemist since 1989, to inspire young students into a lifelong passion for these fields. Programs are implemented in partnership with schools and education programs so activities align with local workforce and learning needs.

Nick Osmo, General Manager, North America, said, “I believe fostering curiosity into STEM at an early age is essential. We want our youth’s innate curiosity to overcome any intimidating aspects that otherwise might deter them so that these powerful subjects become enduring areas of interest, study and eventually a career and passion.”

In today’s world, where science, technology, engineering, and mathematics (STEM) are crucial for the future workforce, high school and post-secondary students often receive the most attention in terms of preparation.

However, it is essential to realise that igniting a passion for science at a young age, even as early as five years old, significantly enhances the likelihood of engaging students in learning and ultimately pursuing careers in STEM fields.

CEF’s outstanding program, You Be the Chemist, is dedicated to this cause. It offers educators many educational resources, including activity guides and workshops. Additionally, the program hosts an annual academic competition at the local, state, and national levels, inviting students in grades 5-8 to compete for scholarships and prizes.

The impact of CEF’s You Be the Chemist program is evident in the remarkable outcomes it has achieved.

The You Be the Chemist program continues to serve as a bridge between businesses, educational institutions, and young students, demonstrating the immense potential of chemistry to create a better world.

Epoxy resins are incredibly versatile and functional, making them essential in various industries. They are used in adhesives, coatings and are critical in many applications. Let’s quickly look into the world of epoxy resins and explore their significant impact on diverse sectors.

Epoxy resins, commonly used in various applications, are typically produced through a chemical reaction between epichlorohydrin (ECH) and bisphenol-A (BPA). This reaction results in speciality resins in either liquid or solid form. The production processes for liquid and solid epoxy resins are similar. Initially, ECH and BPA are combined in a reactor, and a solution containing 20-40% caustic soda is added as the mixture is heated to its boiling point.

After the unreacted ECH evaporates, the resulting mixture is separated into two phases by introducing an inert solvent like Methyl isobutyl ketone (MIBK). Subsequently, the resin is washed with water, and the solvent is removed through vacuum distillation.

Producers incorporate certain additives tailored to the intended application to impart specific properties such as flexibility, viscosity, colour, adhesiveness, and faster curing to the resin.

To transform epoxy resins into a hard, infusible, and rigid material, they must be cured with a hardener. The curing process can occur at a wide range of temperatures, typically between 5 and 150 degrees Celsius, depending on the choice of curing agent. Primary and secondary amines are commonly utilised as curing agents for epoxy resins.

How is it used

Epoxy resins are incredibly versatile and find extensive use across many industries.

- In the adhesive industry, epoxy resins provide exceptional bonding properties, making them indispensable for various applications.

- They also play a crucial role in the coatings industry, where epoxy-based coatings offer superior protection, durability, and corrosion resistance, meeting the stringent requirements of sectors such as automotive, aerospace, and construction.

- In the electronics sector, epoxy resins are employed for encapsulating electronic components, circuit boards, and insulating materials.

- Within the construction field, epoxy resins are utilised for flooring, waterproofing, and concrete repair due to their remarkable strength and chemical resistance.

The aerospace industry uses epoxy resin in many innovative ways, including spacecraft hardware fabrication, space suit reinforcement, and improving flame retardancy. This thermosetting polymer’s combined adaptivity and flexibility make it ideal for use in many space travel solutions. They are also used in spacecraft for staking, sealing, coating, encapsulating, potting, and bonding various structural, electronic, and mechanical components.

They also play a vital role in water resistance and structural integrity in the marine industry. At the same time, the automotive and aerospace sectors rely on them for lightweight composites, adhesives, and coatings that enhance performance and safety.

These are just a few examples of how it contribute to various industries, showcasing their versatility and exceptional properties.

How can Redox help

Redox sells and stores epoxy resin products in various countries, including Australia, the United States, New Zealand, and Malaysia.

Discover how Redox can empower your organisation and unlock the full potential of your sourcing capabilities. Contact us now and experience the advantage that Redox brings.

Tannins are polyphenolic commands and the secondary metabolites of higher plants. Tannins are generally classified as condensed tannins, hydrolysed tannins and phlorotannins. Condensed tannins consist of flavan-3-ol subunit linked together to form oligomers and polymers, whereas hydrolysed tannins are easters of gallic or ellagic acid linked to polyol core.

Phlorotannins are structurally less complexed and occur only in marine brown algae. Because secondary metabolites serve as a part of plant chemical defence system against invasion by pathogens and attack by insects, tannins have shown antimicrobial, anti-parasitic, antioxidant, anti-inflammatory and anti-virus properties. Recently it was reported that condensed tannins significantly reduced methane emission, but hydrolysed tannins failed to affect methane reduction. However, both condensed tannins and hydrolysed tannins reduced Nitrous Oxide emission.

Feedlot and pasture frothy bloat is a serious and often fatal digestive disorder that develops in cattle or sheep when gas produced during fermentation of feeds is trapped within the rumen in the stable form and prevent eructation. Moderate levels of condensed tannins (<50 g/kg DM) reduce protein degradation in the rumen without depressing rumen fibre digestion or DM feed intake. It is generally believed that condensed tannins may bind protein in the rumen and reduce foam stability by avoiding microbial degradation and be absorbed in the small intestine.

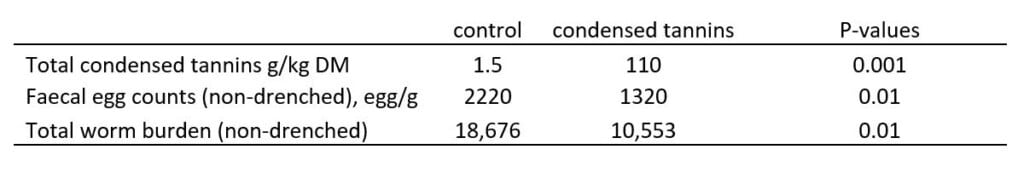

Tannins exert their anti-parasitic effect by decreasing the viability of larvae, thus interfering with egg hatching, and improving the immunity (Table 1). Some tree bark is rich in plant second metabolites, especially condensed tannins.

Recently it was demonstrated that the tree bark-stripping behaviour is primarily for ruminants to acquire condensed tannins to repel gastrointestinal parasites.

Table 1 Effect of grazing condensed tannins forages and control forages on parasite state.

A study compiled by our Redox Animal Nutritionists.

Redox are proud distributors of a range of products from United Initiators including CAROAT®.

CAROAT® is the preferred option to solve problems which are caused by super chlorination when using common pool & spa sanitizers, such as chlorine, bromine and other non-halogenated alternatives.

CAROAT® is characterized by the following:

- odourless

- fast dissolving

- a powerful oxidizer (high oxidation potential)

- oxygen-based, doesn’t contain chlorine

- unaffected by UV degradation

- compatible with sanitizers based on chlorine, bromine and other non-halogen based alternatives

CAROAT® is a non-chlorine oxidizer used for shock treatment applications. It has all the positive functionality of a chlorine oxidizer while avoiding the negative side effects.

CAROAT® is the preferred option to solve problems which are caused by super chlorination when using common pool & spa sanitizers

Download the United Initiators Pool & Spa technical bulletin here and if you have any questions you may refer them to our dedicated Watercare Technical Manager.

This versatile material can also be used in a range of other applications such as –

Denture cleaners: Effective main ingredient in cleaning tablets for dentures.

- Bleaching agent: CAROAT® has a bleaching effect comparable to that of organic peracids; in the TAED/perborate system it is particularly effective at low temperatures.

- Biocidal effect: Suitable as an additive to acidic cleaning agents with bleaching and disinfectant effect.

- Effluent treatment: Oxidative treatment of problematic effluents; sulfide oxidation, nitrite oxidation and cyanide detoxification.

- Plaster additive: Addition of CAROAT® leads to generation of oxygen and improved product characteristics (e.g. thermal insulation, water absorbency, mechanical properties).

- Metal treatment: Microetchant: Use for etching printed circuit boards.

- Textile finishing (shrink proofing of wool)

- Chemical synthesis (production of dioxirane)

- Paper manufacture (repulping, particularly of wet-strength paper).

About United Initiators

United Initiators is a global and leading producer of peroxide-based initiators, Hydrogen Peroxide and specialty chemicals. The company offers a broad range of organic peroxides, persulfates, Hydrogen Peroxide and selected specialty chemicals. Organic peroxides are used in a large variety of polymerization processes and polymer processing applications.

The use of persulfates ranges from aqueous polymerization processes, over electronics, disinfection, cosmetics, metal etching, paper treatment, Oil & Gas exploration to a broad field of bleaching processes. Hydrogen Peroxide is used in consumer goods, disinfection applications and is an enable for the world’s digital economy.

United initiators has several production facilities in Europe, North America, Asia-Pacific, Turkey and India. UI’s mission is to be the best serving peroxide producer for a growing world.

How Can Redox Help?

With Redox, rest assured that our unwavering commitment to excellence will empower your business.

Contact us today to discover how we can be an essential partner in your sourcing strategy, or click here to view the product page.

ICIS Chemical Business Magazine has released their annual Top 100 Chemical Distributors for 2023 and Redox has been ranked as the largest Australian distributor, 12th largest in APAC and the 34th globally.

This list includes 340 of the world’s leading chemical distributors with rankings based upon revenue achieved during Calendar Year 2022.

Of note Redox has climbed 30 places in North America as the company grows it’s presence in the US and Mexican markets, with new locations opened recently in Houston, Dallas and Seattle.

This result is an endorsement of the value that Redox has been able to deliver for clients and our suppliers through the good work of our dedicated team.

Click here to read the full report.

You might not notice it when you look around, but titanium dioxide (TiO2) is everywhere. From the paint on your walls to the sunscreen you apply before heading out, TiO2 is an essential mineral that plays a significant role in various industries.

What is Titanium Dioxide?

First isolated and named by William Gregor in 1791, titanium dioxide is a naturally occurring, chemically stable, non-toxic, and odourless mineral. Its outstanding light-scattering properties make it valuable in multiple applications, such as cosmetics, sunscreens, paints, coatings, plastics, and even food products.

But that’s not all. TiO2 is also a photocatalyst in environmental applications, such as air and water purification, and is a critical component in electronics and solar cells. Its versatility and diversity make it one of the world’s most widely produced and consumed materials.

How is Titanium Dioxide Used?

TiO2 is a versatile mineral that is widely employed across a multitude of industries. It serves as a light-scattering agent in surface coatings and road markings, contributing to a brilliant and reflective finish. In the world of plastics, paper, inks, and rubber, TiO2 functions as a whitening agent, providing increased opacity and visual appeal to these materials.

Moreover, TiO2 is an indispensable ingredient in the production of cosmetic products and sunscreens, owing to its remarkable capacity to protect against harmful ultraviolet (UV) radiation. Additionally, in the food industry, it is used to brighten and whiten various products.

Despite its multifaceted applications, the most significant demand for TiO2 comes from the surface coatings and plastics industries, which account for nearly 80% of its global consumption.

Titanium Dioxide functions as a light-scattering catalyst in surface coatings and road markings, enhancing the creation of a dazzling and reflective surface.

What Influences the Pricing of Titanium Dioxide?

The price of titanium dioxide is subject to various factors, including shipping costs, raw materials such as ilmenite, and the production process. Depending on production location, i.e., China is the world’s second largest TiO2 producer and has a higher percentage of manufacturing via the sulphate process compared to the USA, where chloride TiO2 production is more dominant. There are two primary methods for producing titanium dioxide: sulphate and chloride. Sulphate production is more prevalent, while chloride production is generally considered higher quality, albeit at a higher cost.

These factors all play a role in determining the final price of titanium dioxide, a vital mineral used in a wide range of applications.

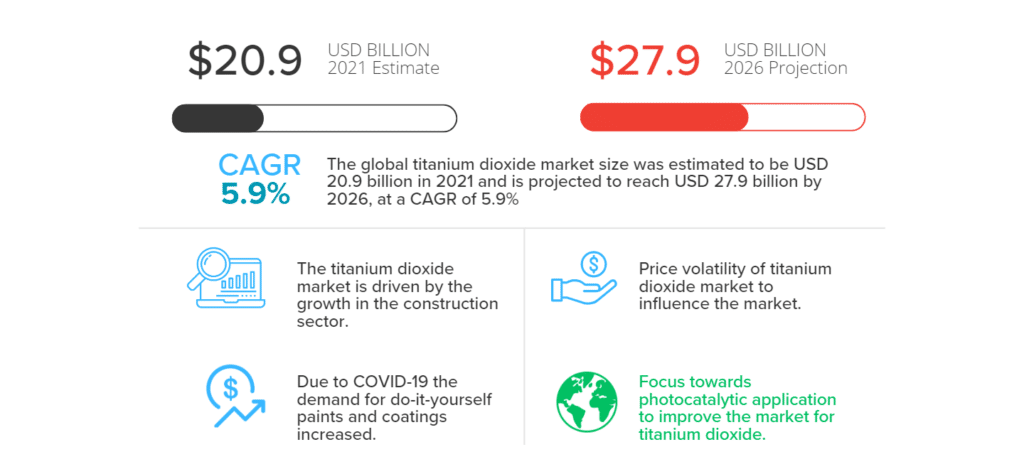

The global titanium dioxide market was valued at USD 20.9 billion in 2021. It is projected to reach USD 27.9 billion by 2026, growing at a cagr 5.9% from 2021 to 2026. It is driven by paints & coatings application in construction, automotive and industries during the forecast period. APAC is dominating the region in paint & coating applications with an increase in demand from China and India.

How Can Redox Help?

We offer Titanium Dioxide in various packaging sizes, ranging from 25kg bags to 500kg and 1000kg bulker bags. The product is available in multiple grades, including Anatase and Rutile, produced through sulphate and chloride production processes. Customers can choose from various options to suit their specific needs.

Trust Redox to deliver the best results for your business. Contact us today to discover how we can be an essential partner in your sourcing strategy.

In recent years, it is widely accepted that based on an ideal amino acid profile, a moderate reduction of dietary crude protein (CP), 20 to 30 g/kg, will not compromise broiler chicken performance.

These reduced CP levels are usually achieved by increasing feed grains such as wheat inclusion at the expense of soybean meal, relatively more starch replacing fat as the non-protein energy source. It is reported that increased non-starch polysaccharides (NSP) presented in wheat will enhance faecal bile acids loss, resulting in either increased bile acids pool or bile acids deficiency.

Traditionally bile acids are considered to be bio-surfactants, assisting intestinal digestion and absorption of lipids and fatty soluble vitamins such as Vitamin A, D, E and K, and thereby improving nutrient utilization. Recently it has been shown that bile acids act as regulators of gut microbiome and play a key role as signalling molecules by modulating cell proliferation, gene expression, lipid and glucose metabolism. To evaluate if the reduced CP diet could affect fat digestibility, the University of Sydney conducted a broiler chicken trial by adding the exogenous bile acids to both normal CP and reduced CP diets.

Standard, normal protein (SC) diets were formulated to meet or exceed the 2019 Aviagen Ross 308 nutrition specifications and reduced protein (RC) diets were formulated with a 3 g/kg CP reduction in the starter (0-14 d), grower (15-28) and finisher (29-42) phases. Another two treatments consisted of the SC and RC supplemented with the exogenous bile acids 200 mg/kg, respectively. All diets contained 1000 FTU phytase and 4000 U Xylanase.

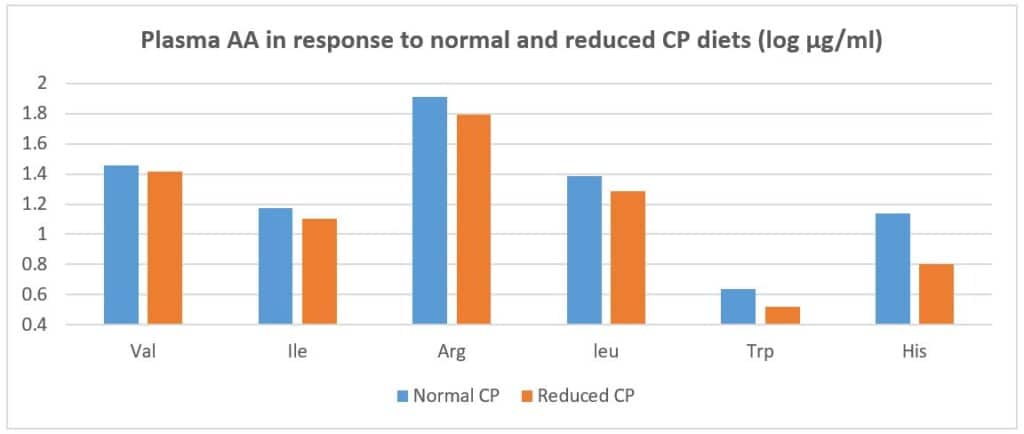

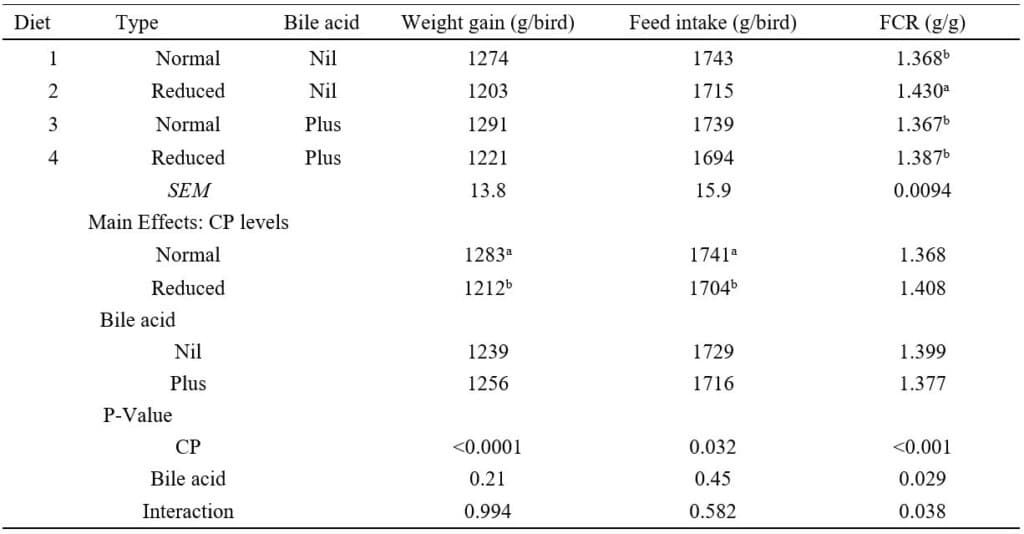

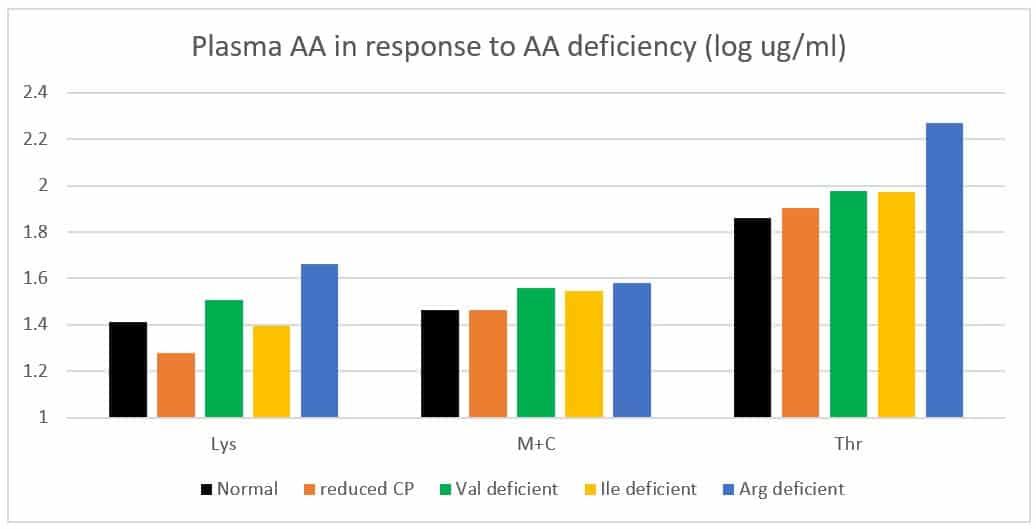

Surprisingly, reducing 30 g/kg CP significantly depressed body weight gain and feed intake by 4.8 % and 2.8%, respectively (P < 0.01) although chicken performance fed on RP diets exceeded the Ross 2022 male performance objectives by 4.31% for weight gain (3361versus 3222 g) and was superior by 2.76% in FCR (1.475 versus 1.517). Figure 1 clearly showed that the current ideal amino acids profile resulted in significant lower plasma Valine, Isoleucine, Arginine, Leucine, tryptophan and histidine concentrations in RP diets, indicating that the current ideal amino acids profile could not support 30 g/kg CP reduction although it might achieve commercially satisfied performance.

Figure 1. Plasma AA concentrations in response to normal and reduced CP diets (log µg/ml)

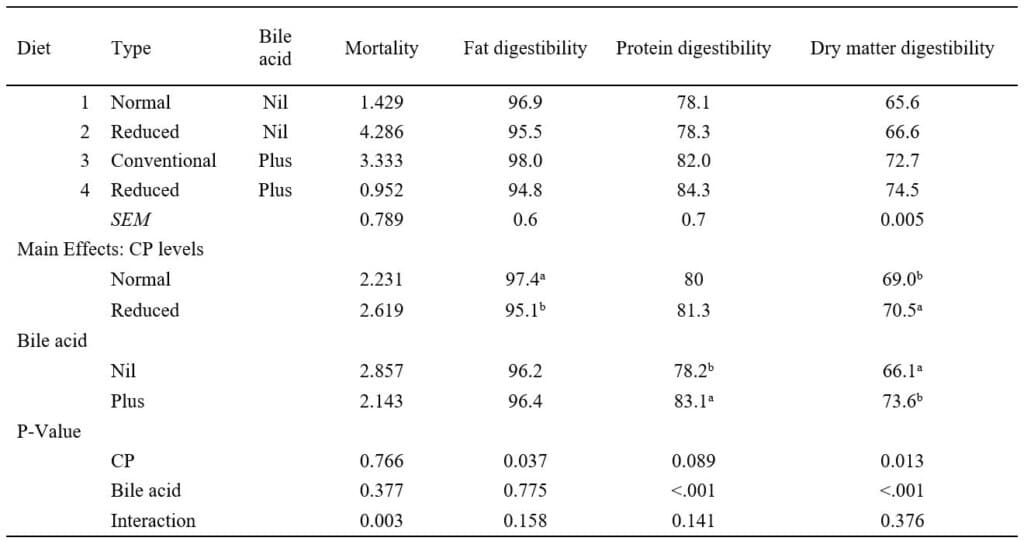

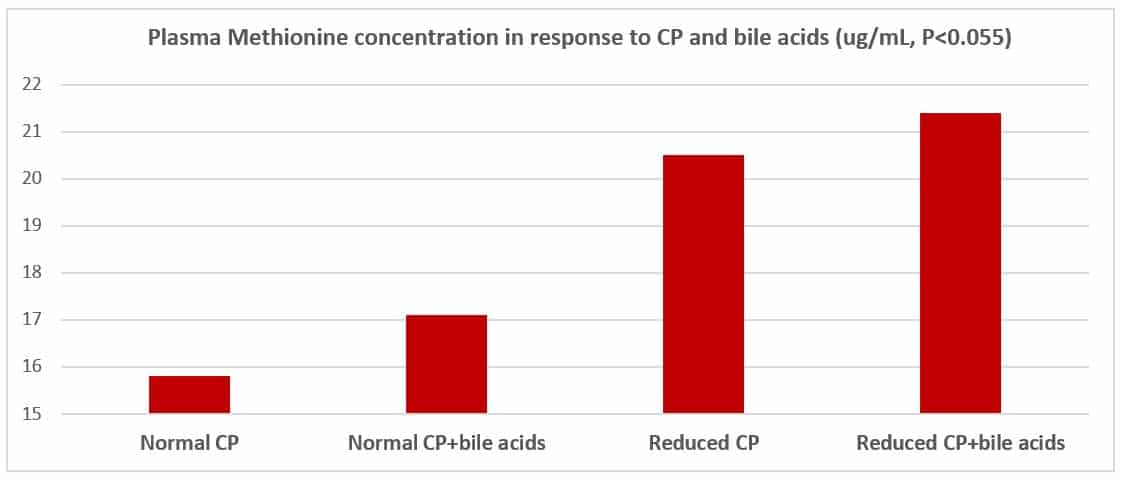

Interestingly, the addition of the exogenous bile acids had no effect on crude fat digestibility but significantly improved crude protein and dry matter digestibility (Table 1) possibly due to reduced endogenous bile taurine loss. In Table 1, it is also shown that adding bile acids to the RP diet, significantly reduced mortality rate (P < 0.003).

Table 1. The effect of dietary treatments on the mortality and digestibility of fat, CP and dry matter (%)

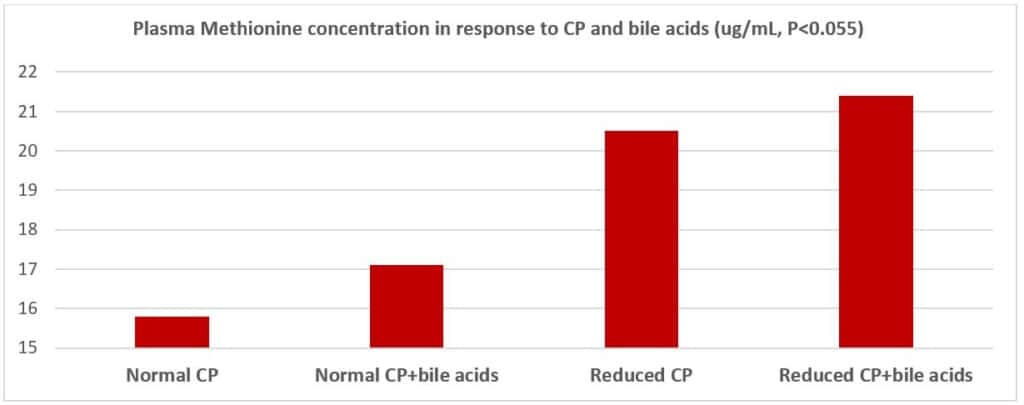

In RP diets, due to other amino acids such as valine, isoleucine and arginine limitation, dietary methionine becomes more surplus but adding bile acids significantly increased plasma methionine concentration (Figure 2). Therefore, the efficacy of bile acids may be related to dietary methionine concentration which could convert to taurine. In general, in grower period (15-28), adding the exogenous bile acids to a RP diet achieved the best chicken performance and FCR was improved by 5 points (Table 2).

Figure 2. Plasma Methionine concentration in response to dietary protein and bile acids addition (µg/mL)

Table 2. The effect of dietary protein levels and bile acids on growth performance (15-28 days)

A study compiled by our Redox Animal Nutritionists.

In recent years, the poultry and pig industry has been successfully developing reduced crude protein (CP) diets to reduce Nitrogen pollution and improve the litter quality. It is reported that 2.5%-unit crude protein reduction in poultry or pig diets will reduce ammonia by 25%. Considering 1 MT ammonia is equivalent to 2.11 MT carbon dioxide, this trend will have a tremendous impact on climate change. However, nutritionists need to do more to deal with reduced protein diets.

1. Reduced protein diets and limiting amino acids (AA)

Traditionally, in wheat-soybean meal-based poultry diets, unbound crystalline L-methionine, L-Lysine and L-Threonine have been routinely added to meet chicken growth requirements. It is clear now that by further adding L-Valine, L-Isoleucine and L-Arginine, the crude protein level could be reduced by 1.5 to 2% unit but not compromise chicken performance. It is noticed that in reduced protein diets, dietary valine or arginine deficiency will result in plasma Lysine, Methionine and Threonine accumulation; Dietary isoleucine deficiency will result in plasma methionine and threonine surplus, indicating that in reduced protein diets, if L-Valine, L-isoleucine and L-Arginine were not added, dietary lysine, methionine and threonine cannot be fully utilized by chickens to contribute to muscle growth. In particular, dietary Arginine deficiency resulted in a considerable surplus of threonine, affecting mucus secretion. (Figure 1).

Figure 1. Plasma AA concentrations in response to dietary AA deficiency

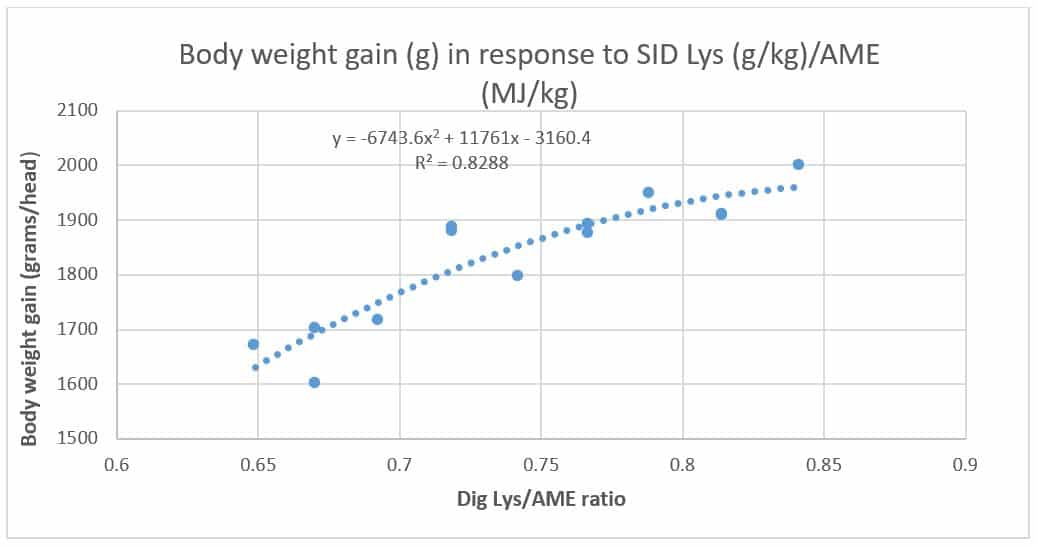

2. Optimal SID Lysine (g/kg) to AME (MJ/kg) ratio in reduced protein diets

While formulating a reduced protein diet, nutritionists will usually use more grains and reduce oil or fat contents. Considering the higher energy efficiency of oil or fat, it is not clear yet if we need to increase apparent metabolizable energy (AME) requirement in reduced protein diets. However, in 2018, the University of New England (UNE) published a broiler chicken trial paper to show that AME requirement might mainly depend on dietary lysine concentration. In grower period, the optimal SID lysine (g/kg) to AME (MJ/kg) was determined to be 0.88 (Figure 2).

Figure 2 Body weight gain in response to SID Lys/AME ratio on 14-35 days

3. Endogenous loss of taurine in reduced protein diets

It is noticed that in reduced protein diets, more starch will replace fat as the dietary non-protein energy source, leading to more faecal bile acids loss. Recently, the research in Massey University demonstrated that the major endogenous amino acid loss in broiler chicken bile would be taurine. Considering taurine is an important anti-oxidant to regulate immune system health, in stress situation, the reduced protein diet might result in disease infection. It is widely known that taurine is produced by cysteine in chicken body and dietary methionine can convert to cysteine. In a recent broiler chicken trial conducted in the University of Sydney, adding exogenous bile acids to the reduced protein diets significantly reduced mortality rate due probably to increased plasma methionine concentration (Figure 3).

Figure 3. Plasma methionine concentration in response to bile acids addition

4. Reduced protein diets by exogenous protease supplements

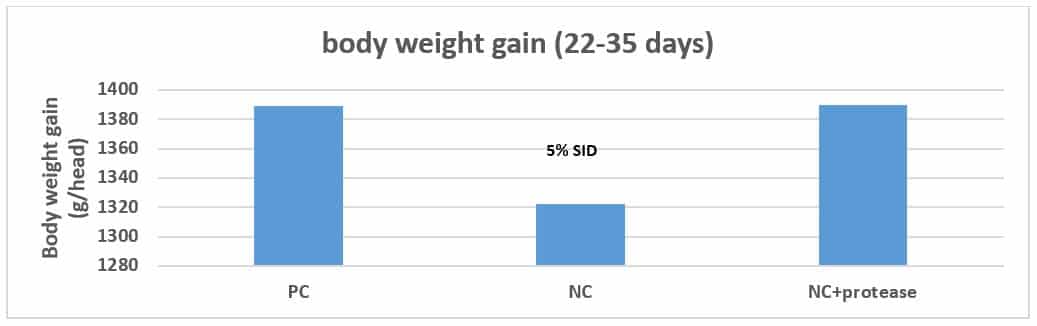

To some degree, in reduced protein diets, dietary protein levels are determined by dietary standard ileal digestible (SID) lysine concentrations because other SID essential amino acids to SID lysine ratios are used in ideal amino acids profile. It is estimated that 5% SID lysine reduction will reduce dietary crude protein by 1% unit. In practice, the efficacy of protease is mainly determined by undigested protein concentration in feed ingredients. Usually when SID lysine (%) to undigested protein (%) ratio is lower than 0.3, dietary SID lysine and other essential amino acids could be reduced by 5% (Figure 4).

Figure 4. Bodyweight gain in male Ross 308 broilers from 22-35 days post-hatch (P = 0.061).

5. Phosphorus and phytase in reduced protein diets

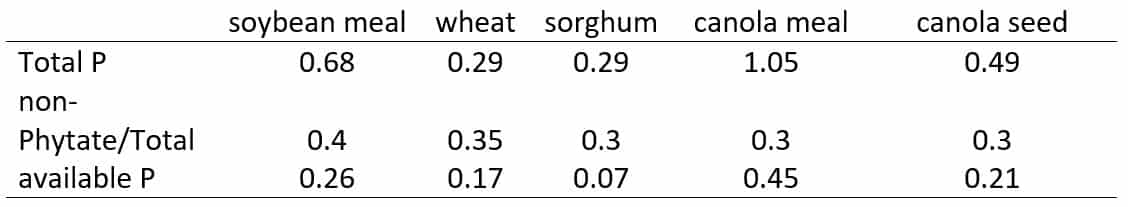

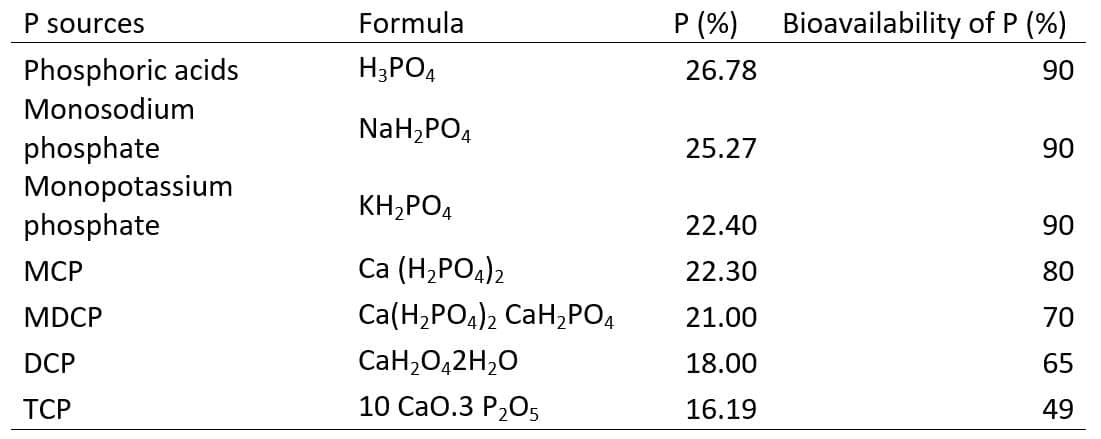

In reduced protein diets, soybean meal and other protein ingredients will be partially replaced by grains and crystalline amino acids. Phytate phosphorus and available phosphorus variation in feed ingredients (Table 1) may increase inorganic phosphorus usage. We also need to reconsider phosphorus matrix value in phytase and absorption rate in inorganic phosphorus (Table 2). In table 1, it is clearly show that in sorghum-based diets, the matrix value of phosphorus in phytase may be higher than that in wheat-based diets, but it will be lower in reduced protein diets because of lower inclusion levels of soybean meal. In table 2, it is shown that when formulating reduced protein diets, both inorganic phosphorus contents and their bioavailability should be considered. In general, inorganic phosphorus bioavailability is strongly related to citric acid solubility and current DCP and MDCP practical bioavailability could be predicted by citric acid solubility.

Table 1. Total P and available P in feed ingredients (%)

Table 2. Phosphorus bioavailability from different sources

6. Nucleotide supplements in reduced protein diets

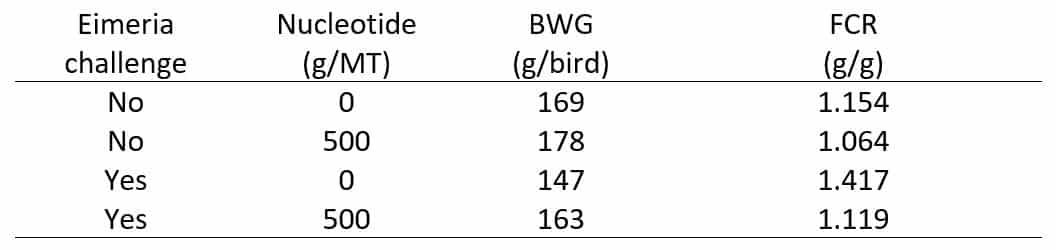

In reduced protein diets, almost all essential amino acids requirements could be met by adding crystalline amino acids. The reduced protein contents mainly come from non-essential amino acids concentration including glutamine and aspartic acids, which are precursors to produce nucleotides in the chicken body. In cocci vaccination and high-stock density stress situation, this exogenous production of nucleotides might not be sufficient to support a healthy immune system. Table 3 clearly shows that in Eimeria challenging situation, adding Nucleotides (IMP) significantly alleviate the challenging impact on chicken body weight gain (BWG) and feed conversion ratio (FCR)

Table 3. Effect of Nucleotides on chicken performance at d 11-15 after challenging

7. Gut health concern in reduced protein diets

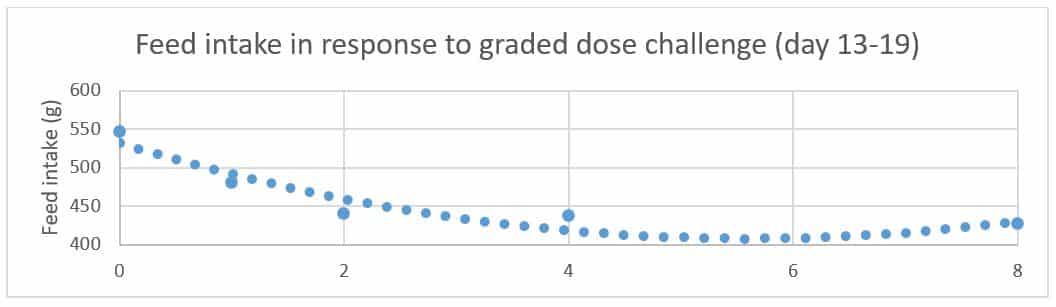

In Australia and USA, coccidiostats are considered as antibiotics and are banned in antibiotics free production. Currently in breeder and claimed antibiotics free chicken production, Eimeria vaccination has been widely practiced controlling cocci infection. However, broiler chicken feed intake is sufficiently reduced by the vaccination challenging dose and each double dose will worsen FCR by 9 points (Figure 5). Some new gut health related feed additives are necessary in reduced protein diets for young animals to fight against disease challenging.

Figure 5. Feed intake in response to graded dose Eimeria vaccination challenging

- Mannanase: Β-Mannan in soybean meal is one of the main antinational factors to decrease the efficiency of nutrient use. Supplementation of the exogenous mannanase has been demonstrated to increase chicken feed intake, significantly reduce coccidial lesion sores and increase breast production. Dietary AME can be saved by 50 kcal/kg due to reduced immune response sensitivity. The efficacy of Mannanase addition is strongly related to soybean meal inclusion levels and optimal crude fiber (%) to SID Lysine ratio is about 1.45 for Mannase response.

- Glucose oxidase: Cell-mediated immunity is thought to be important in the resistance of chickens to infection by coccidia. It has been demonstrated that sporozoites of Eimeria tenella are very sensitive to superoxide ions. Adding exogenous glucose oxidase to reduced protein diets could consume surplus oxygen and increase the shelf life of diets. More importantly, it can endogenously produce hydrogen peroxide to directly kill Eimeria and improve gut health. The heat tolerable glucose oxidase is commercially available now.

- Antimicrobial peptide: Previously it targets Gram negative bacteria such as E coli and Salmonella. Right now, new product is available to protect from Gram positive and negative bacteria infection including colostrum perfringens. Usually, Gram positive bacteria are acids resistance and organic acids are useless in Gram positive bacterial infection.

- Postbiotics: different from traditional probiotics, this postbiotics also includes metabolites from probiotics such as peptides, lipoprotein and bacteriocins, more widely building up the first defense line

- Tri-butyrin: it will promote the overall gut health by facilitating tight junction assembly.

8. Other concerns regarding to reduced protein diets

In reduced protein diets, feed grains such as wheat inclusions will usually increase at the expense of soybean meal. The current supplemental dosage of xylanase needs to be increased to completely degrade soluble Xylan in wheat and reduced viscosity.

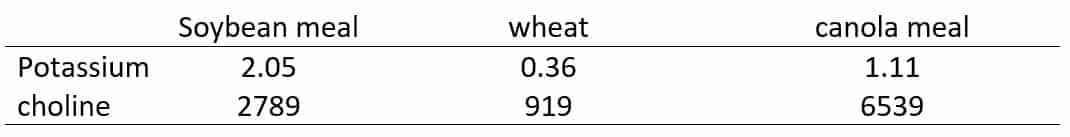

In addition, compared with wheat, soybean meal contains more potassium and choline (Table 4). Therefore, extra potassium bicarbonate or potassium chloride and choline chloride may be increased in reduced protein diets.

Table 4. Potassium and choline concentration in feed ingredients (%)

A study compiled by Redox Animal Nutritionists.

A surfactant, also known as a surface-active agent, is a substance that lowers the surface tension between two substances. It is a molecule that contains both hydrophilic (water-loving) and hydrophobic (water-hating) parts, allowing it to interact with water and oil.

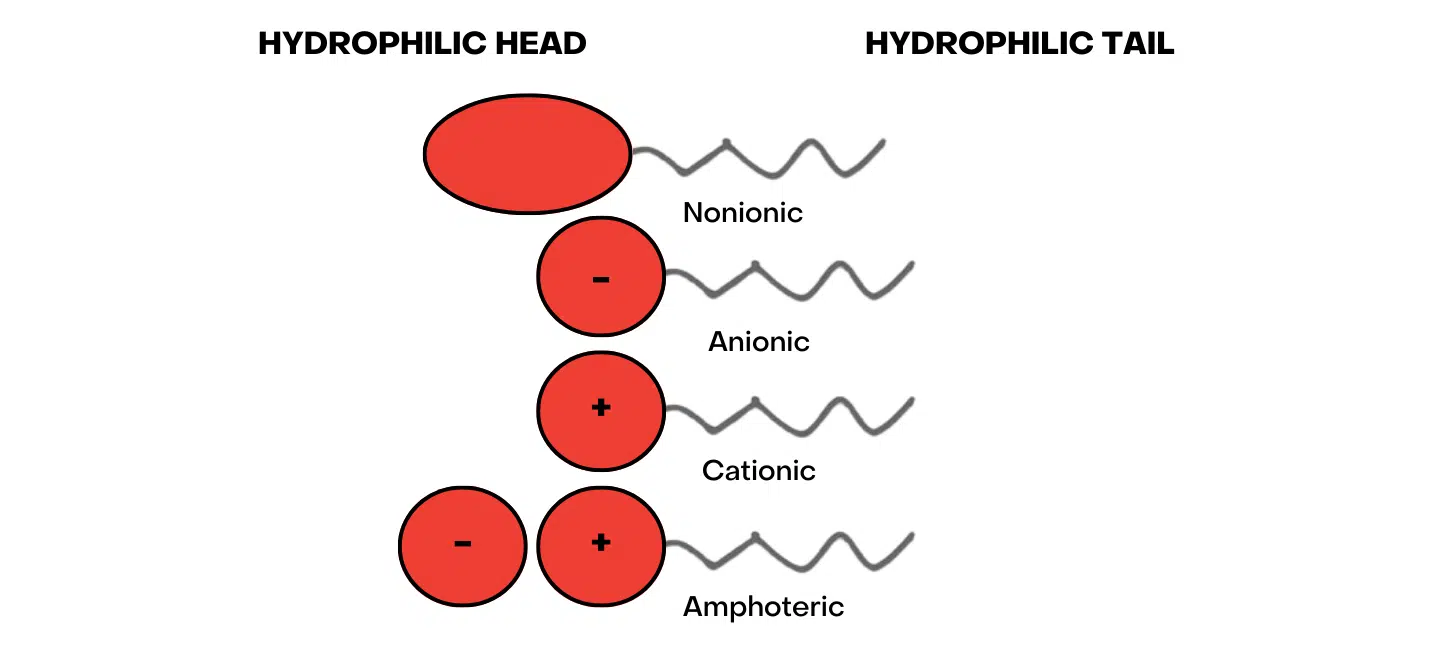

Surfactants are a wide spectrum of products but are broadly classified as Anionic, Nonionic, Cationic or Amphoteric depending on whether the electrical charge is positive, negative or neutral on the hydrophilic head.

Surfactants are commonly used in cleaning products such as detergents, soaps, and shampoos. They can break down oils and dirt and help them mix with water for easier removal. They are also used in industrial processes such as oil recovery and in medical applications such as lung surfactants, which help maintain the structure of the lungs and prevent collapse.

Examples of surfactants include sodium lauryl sulphate, commonly found in household cleaning products and personal care items, and polysorbate 80, used in food, cosmetics, and pharmaceuticals.

Surfactants are used in a wide variety of products, including:

- Detergents and cleaning products: Laundry detergents, dishwashing liquids, all-purpose cleaners, and bathroom cleaners all contain surfactants that help to remove dirt, oil, and grease from surfaces.

- Personal care products: Shampoos, body washes, hand soaps, and toothpaste all contain surfactants that help to clean and remove oils from the skin and hair.

- Cosmetics: Makeup removers, facial cleansers, and body wash contain surfactants that help break down and remove makeup and other impurities.

- Food and beverages: Emulsifiers and stabilizers are surfactants used in food and beverage products to help mix ingredients that would not usually mix well, such as oil and water.

- Agriculture: Surfactants are used in agricultural products, such as herbicides and pesticides, to help them stick to plants and improve their effectiveness.

- Petroleum: Surfactants are used in the petroleum industry to improve oil and gas flow through pipelines and help recover oil from underground reservoirs.

- Lubricants: By adding surfactants to car engine lubricants, it becomes possible to prevent particles from adhering to engine parts, enabling the parts to move smoothly and maintain the proper functioning of the car.

Surfactants have several unique qualities that make them useful in a wide range of applications:

- Surface tension reduction: Surfactants have the ability to reduce the surface tension between two substances, such as water and oil. This allows the substances to mix more easily and enhances the ability of the surfactant to clean, emulsify, or disperse.

- Amphiphilic nature: This unique structure allows surfactants to interact with water and oil hydrophilic (water-loving) and hydrophobic (water-hating), essential for their cleaning use and emulsifying.

- Self-assembly: Surfactants can self-assemble into organized structures, such as micelles or bilayers, in certain conditions. This allows them to form stable emulsions, which are essential in creating many products such as lotions, creams, and paints.

- Interfacial activity: Surfactants are active at interfaces, such as the boundary between two liquids or a liquid and a solid. They can adsorb to the surface of a substance, which can change its surface properties, such as its wetting or adhesion behaviour.

Overall, these unique properties make surfactants extraordinarily versatile and valuable in a wide range of applications, from cleaning products and personal care items to industrial processes and medical applications.

Our Partnering Manufacturers