Today is World Water Day, focusing on expediting efforts to address the global water and sanitation crisis. Since water is a fundamental need for everyone, it is essential that each one of us takes responsibility and takes action towards this cause.

In 2021 Redox commenced support for Médecins Sans Frontières (MSF) to aid their critical global efforts. Our donations help enable the teams at MSF to respond promptly to emergencies and deliver superior medical care to those in dire need-no more important than clean, accessible water.

MSF operates in countries where access to water can mean the difference between life and death. Inadequate water results in crop failure and suffering, while excess water leads to natural calamities like floods, landslides, and epidemics. Clean water is crucial in preventing waterborne illnesses.

Sera James, a resident of Akello village, shares a laugh with her friends as she draws water from a pump MSF teams have just installed to improve the community’s access to clean water during the dry season. Pibor country, South Sudan, March 2022.

NJIIRI KARAGO/MSF

During times of crisis and disaster, the most vulnerable, such as children, pregnant women, the elderly, and displaced individuals, are usually the first to bear the brunt. In Afghanistan and Syria, people are cut off from water supplies. In contrast, the Sahel region’s lack of food and water exacerbates existing inequalities. Eastern Africa experiences relentless storms and cyclones, causing widespread destruction.

Humanitarian medical needs continue to grow in these regions, and climate crises are emerging as a new area of concern for aid organizations. Drought in Madagascar is leading to increased malnutrition, while frequent extreme weather events are destroying livelihoods in countries such as Malawi. Persistent flooding in South Sudan has resulted in a rise in malaria cases.

These crises are often intertwined, with water being the common denominator.

MSF teams try out a water pump as part of a bid to provide clean water and latrines to displaced people in Rho camp—Democratic Republic of Congo, December 2021.

ALEXIS HUGUET

Despite the challenges facing the world’s freshwater resources, there is still hope for a sustainable future. By taking action to conserve and manage our water resources, we can help ensure a future where clean and safe water is available to everyone. We can make a difference by adopting sustainable water practices in our daily lives, such as reducing water usage, fixing leaks, and using water-efficient appliances. Organizations and governments can also play a significant role by implementing policies and initiatives that promote sustainable water management. Let us take inspiration from World Water Day to work together towards a future where access to fresh water is a reality for all.

Join us in supporting the critical work of Médecins Sans Frontières by clicking here to donate. Your contribution will help MSF continue providing lifesaving care in emergencies and beyond, ensuring that vulnerable communities receive the help they need even after the headlines have faded.

One of the most powerful solutions to ensure a safe mine environment is fire retardant anti-static (FRAS) materials, which protects against all kinds of hazardous situations like fuel fires or explosions caused by heat build-up, static sparks, and other combustible substances that could seriously compromise your mine’s safety.

Materials such as rubber, polyurethane, PVC, polyethylene, polypropylene and polyester are often used to make base materials that are then manufactured into products for underground coal mining. Fibre-reinforced resin materials such as fibreglass and carbon fibre composite are also used.

The products manufactured include ventilation sheeting (brattice) and ventilation stoppings, ventilation ducting (rigid and flexible), dust curtains, venturi blowers, air fans, pipes, conveyor belting and conveyor accessories.

Recommendations on FRAS materials

Mine operators of underground coal mines must ensure that control measures are implemented for products subject to the accumulation of static charge. The control measures should include the following:

- Procedures to verify the products are installed per the manufacturer’s directions for static discharge.

- Appropriate measures are implemented to ensure that the properties of FRAS materials are maintained over time.

Manufacturers of FRAS-rated materials must ensure that testing is undertaken in accordance with the relevant requirements of MDG 3608 by an independent testing facility for:

- All FRAS material intended for use in an underground coal mine

- Any change of material composition or manufacturing technique for a FRAS-rated material, including changes of colour, to verify the suitability of the material.

Manufacturers and suppliers of products incorporating FRAS materials as components must ensure that:

- The product’s design incorporates suitable controls to prevent the accumulation of a static charge on the FRAS components.

- Instructions for the safe use of the product include mounting or suspension requirements to prevent the accumulation of a static charge on the FRAS components.

- Any change of material composition or change to the product design, including changes of colour, size or placement of eyelets, rivets or mountings, are tested in accordance with the relevant requirements of MDG 3608

- The product is suitably marked to indicate compliance with MDG 3608.

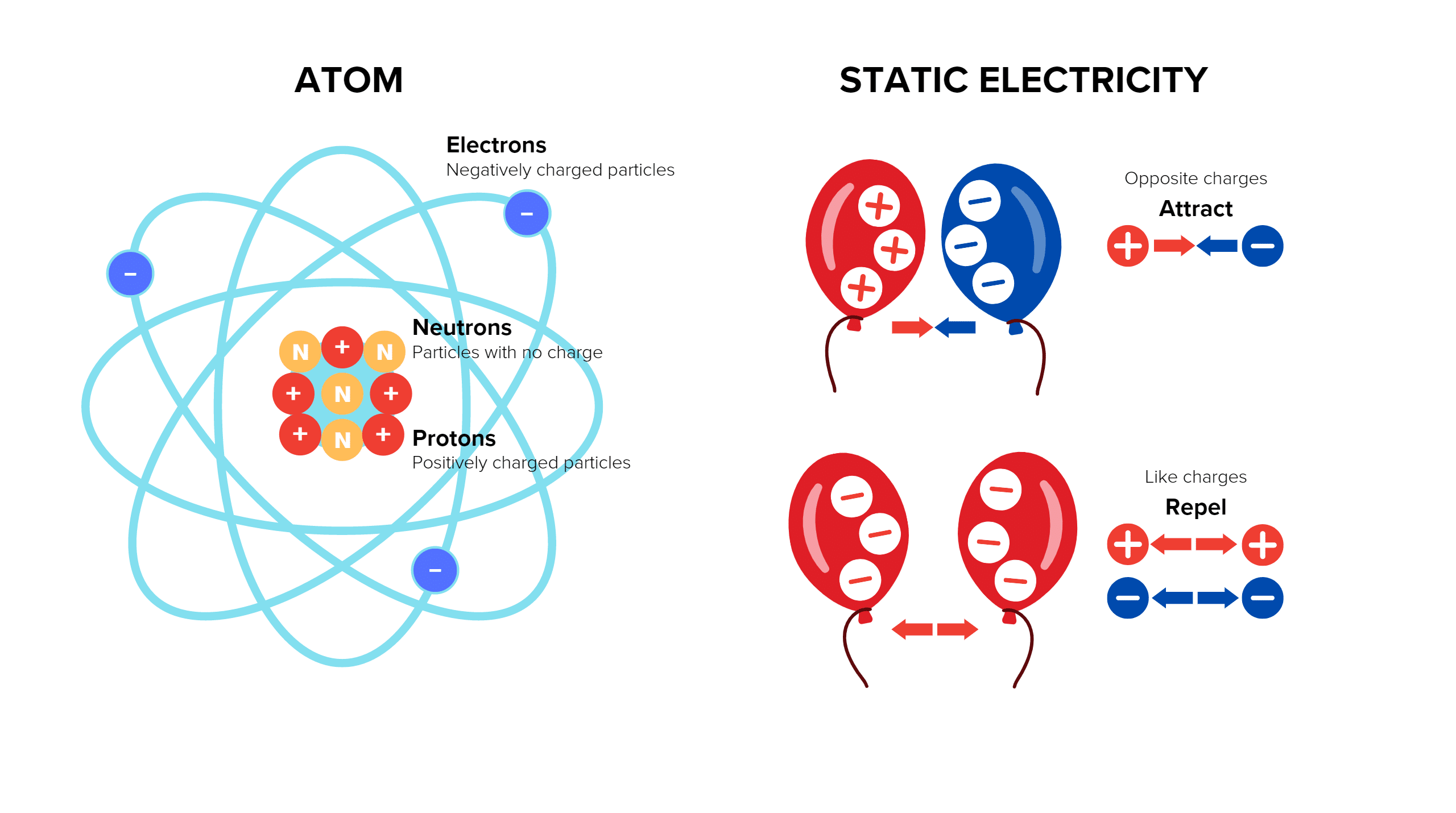

Every object is made of atoms that are typically electrically neutral. They contain an equal number of protons (positive charge) within their nucleus and electrons (negative charge) surrounding the nucleus. Static electricity occurs when there is a separation of positive and negative charges within or on the surface of a material or between materials. Electrons may move from one object to another, leaving one object with a negative charge and the other with a positive. When the objects are separated they retain the charge imbalance.

How can we help?

To minimise risks, improve occupational health and safety hazards, and, importantly, minimise underground ignitions, fire retardant anti-static (FRAS) materials are now required in all NSW underground mines, monitored by the NSW resources regulator.

Redox offers many polymer/composite options for differing FRAS application solutions.

Contact our Plastics division today if you would like to learn more about material solutions supported by our many international principal partners.

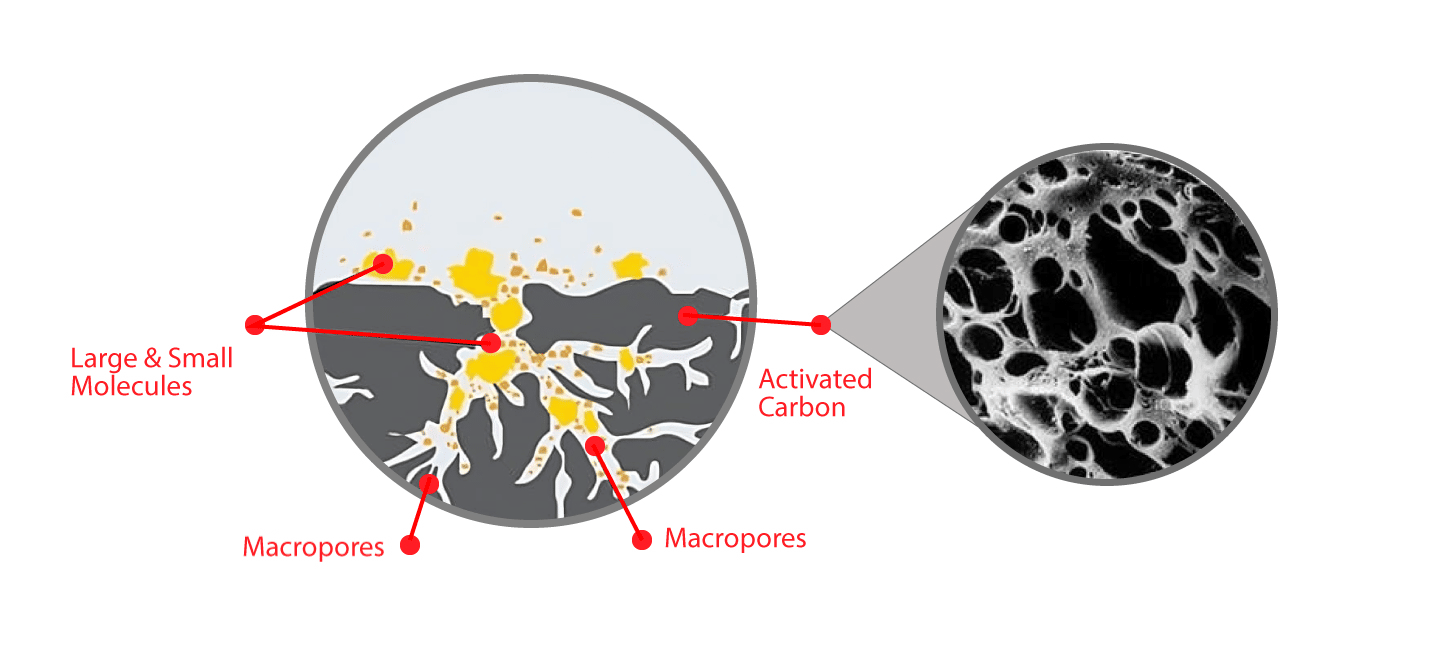

Produced from carbon-rich organic materials, activated carbon’s superior performance as an adsorbent lends itself to a growing list of applications as environmental regulations continue to become more stringent.

Activated carbon is a game-changing adsorbent, revolutionising how industries tackle contaminants and unwanted particles in liquids or gases. Pollution control efforts are particularly taking advantage of its capabilities, with reports pointing towards an optimistic future – all thanks to the growing call for environmental solutions globally.

How is Activated Carbon being used in industry?

Activated carbon is an incredibly versatile compound that serves a range of diverse functions.

- From the granular medium traditionally used to trap pollutants from liquids and gases to

- pellets designed explicitly for tackling volatile organic compounds (VOCs) and Hydrogen Sulfide (H2S) in gas filtration,

- it even comes in powder form – which can be added directly into liquid or soil to absorb toxins easily.

Its remarkable properties have enabled some incredible advancements across multiple industries.

While Activated carbon has become a powerful ally in multiple industries, from purifying potable and wastewater to cleaning out toxic gases from the air we breathe, it also plays an essential role in soil remediation by removing dangerous pollutants like PFAS and other organic compounds.

Even beverages can benefit– with Activated carbon able to strip wine and juices of their unwanted colour or toxins, such as patulin found commonly in apple juice!

Natures renewable resource

Customers are increasingly turning to sustainable solutions – unlike other forms of activated carbon, coconut shells and wood are renewable resources, each with unique properties when it comes to removing impurities.

In particular coconut shells are an incredibly sustainable solution to global raw material needs. Renewable and accessible within six months, coconuts outshine common alternative materials such as coal or wood that can take millions of years and decades to form. Not only do coconut trees capture CO2 from the atmosphere, but their harvesting is a by-product of our food industry – making them earth-friendly and beneficial in other ways.

Activated carbon is an effective adsorbent because it is a highly porous material and provides a large surface area to which contaminants may adsorb.

Using it to produce activated carbon prevents it from being wasted and potentially burnt as fuel. In fact, every part of the coconut has a use, and there is no waste. The water, meat, husk and shell are all used across various industries.

Recent market reports point to an optimistic future driven by demand for its environmental uses. With a heightened awareness surrounding eco-friendly products like coconut-based activated carbon, new possibilities present daily as we uncover just how powerful this substance truly is in the fight against pollution.

How can we help?

Despite a range of competitor adsorbents available, activated carbon continues to lead the way across numerous applications. Thanks to solid growth prospects in key regions and industries, demand for this versatile material is set to remain healthy in the coming years. As a result, companies providing high-quality activated carbon will be well-positioned to capitalise on this trend.

Redox proudly offers a vast selection of activated carbon tailored to suit any application. From 25kg bags up to 500 kg bulker and with impregnation options – Redox only sources the highest quality carbons to suit your application through our trusted partner.

Unlock the potential of your sourcing strategy with Redox. Our experts are ready to help you realise a new level of success. Contact one of our experts today.

Through a careful and detailed analysis of a customer’s crops, fertiliser application rates and exploring Redox’s range of products, we aim to deliver the best advice tailored specifically to each grower.

At Redox, we empower our Agronomists to drive success on the farm. Our experienced team of specialists are eager to find solutions that enable our partners in agriculture to optimise their yield and reduce costs while maintaining a high production level.

“I take great pride in the positive outcomes we produce on farms,” said veteran Redox Agronomist Ian Gardner.

“…our work and dedication on a Raspberry crop recently resulted in 25 tonnes per hectare within 18 months – exceeding what standard practices could have achieved alone! The farmer was thrilled with this result.”

“Watching over the Dolomia Plus Raspberry crop during its final harvest was a sight to behold. After six years in Adelaide Hills, South Australia, these resilient plants had defied an unseasonably cold winter and I walked through them recently when temperatures still hovered around 9 degrees Celsius – yet they endured proudly until their end of season finale.” Ian Gardner, Redox Agronomist.

Welcome aboard Diego

Diego Farias is our newest Agronomist; he hails from Brazil, bringing a wealth of knowledge and experience to Redox and boasts an impressive background and expertise. With his Bachelor’s Degree in Agriculture as well as honing his skills specializing in plant nutrition, he has gained invaluable experience from internships at soil and plant analysis laboratories to working with broad acre crops such soybean seed, cotton & corn for years.

In addition to this impressive work history Down Under he has been passionate about protected cropping (Tomato Capsicum Eggplant Cucumber etc.), providing agronomic aid for vegetable growers including managing soil/plant nutrition issues alongside pest & disease control plus hydroponic systems.

“Going on-site and meeting with our customers to understand what they need is crucial, but it’s also a wonderful way to connect with them and get to know them personally. Growing up on a farm, my love for agriculture goes back to being a young boy. I’m now driven by an unrelenting dedication and passion to share that knowledge with the growers who depend on me; together, we have forged strong relationships built of mutual understanding and respect,” says Diego Farias, our newly appointed Agronomist working out of our Adelaide office.

As innovators of new farm technologies and educators for existing practices, agronomists ensure that crops can be grown sustainably yet profitably — a crucial balance when it comes to protecting our planet’s future.

Our Redox Agronomists will

- Collect and analyse data and samples of produce, feed, and soil to study other factors affecting production.

- They will advise farmers about techniques for improving the production of crops, pest/weed control, soil improvement etc.

- They will also study environmental factors that affect commercial crop production, pasture growth & animal breeding and develop procedures and techniques for solving agricultural problems & improving production efficiency.

We offer an exciting environment for career-driven individuals who share our commitment towards progress and innovation.

If this sounds like you, we would love to hear from you.

Not long after, French chemist Nicolas Leblanc produced sodium carbonate in 1791; pharmacist Valentin Rose the Younger discovered Sodium Bicarbonate in 1801. Neither Leblanc nor Younger could have imagined their discoveries’ impact on future generations.

How is it made, or where do we find it?

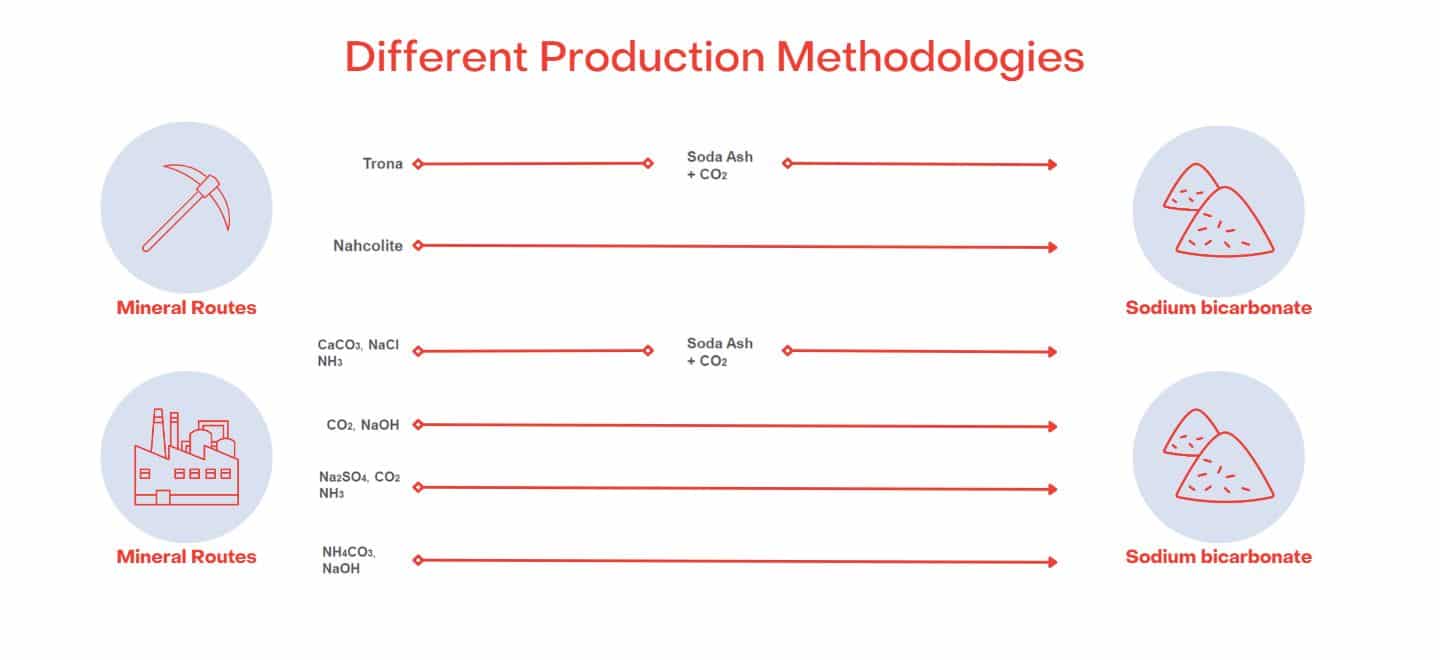

Sodium Bicarbonate is generally synthetically manufactured using the Solvay or the Trona Process.

The Solvay process is an industrial method used to produce Sodium Bicarbonate, commonly known as baking soda. The Solvay process is the reaction of Sodium Chloride, ammonia, and carbon dioxide in water.

Alternatively, the Trona process converts naturally formed/mined soda ash into bicarb.

However, it can also be found naturally occurring in evaporated lake basins worldwide. The largest commercially viable source is Natural Soda in Colorado, USA, which has full organic certification.

Different uses of Sodium Bicarbonate in the food & beverage industry

The flexibility of Sodium Bicarbonate is an undeniable asset for many industries, none more so than the food and beverage industry.

In baked goods, it acts as a leavening agent that produces carbon dioxide when combined with an acidic ingredient such as vinegar or lemon juice. This causes the dough to rise, creating lighter and fluffier baked goods like cakes and muffins. Not only that, Sodium Bicarbonate can also be used to make carbonated beverages like sodas and sparkling waters by dissolving it into water.

The dissolved sodium bicarbonate can then be added to other ingredients like flavourings, syrups, and colourings to create a refreshingly fizzy drink.

Lastly, Sodium Bicarbonate can also be used to tenderise meats for marinades or sauces, as its alkaline nature helps break down tough fibres in the meat’s muscles.

Sodium Bicarbonate or bicarbonate of soda, is a popular baking ingredient. It gives foods like bread, cakes, muffins, and cookies a light, fluffy texture.

Sodium Bicarbonate’s application in animal feed

Sodium bicarbonate is a vital ingredient in animal feed due to its numerous benefits.

It serves as an excellent source of electrolytes essential for healthy bodily functions. It also helps to maintain proper pH levels in the body, which improves digestion and increases nutrient uptake.

In addition, Sodium Bicarbonate can help reduce the build-up of lactic acid in the muscles, allowing animals to perform better during strenuous activity. Besides that, it can also act as a buffer against digestive upsets such as acidosis and scours and protect against microbial toxins.

All these benefits make Sodium Bicarbonate an essential ingredient in animal feed for optimum health and performance.

But its utility goes beyond the Food and Feed industries. For example:

- It’s commonly used in water treatment and swimming pools for pH adjustment.

- Being an alkali, it assists in removing stains in cleaning and is used in laundry and dish detergents.

- Bicarb is hygroscopic, meaning it absorbs moisture and hence odours.

- Finely powdered bicarb is injected into industrial exhaust stacks to de-sulphurise flue gas before it can escape into the atmosphere.

- Mix it with a bit of water to make a paste, and it relieves insect bites on your skin.

- Calms indigestion and heartburn.

- It’s the abrasive in toothpaste (also helps to remove odours in your breath).

How can we help you?

In 2022, despite the unprecedented supply chain hurdles of a global pandemic, Redox successfully distributed Sodium Bicarbonate across Australia and New Zealand to meet growing demands in both countries and Malaysia.

Redox’s Sodium Bicarbonate is available in various packing sizes, including 25kg bags and bulker bags, coming in a range of food, feed and industrial grades and conforming to FAMI-QS and Food Safety Regulation.

Contact one of our experts to discover how Redox can be essential to your sourcing strategy.

In September of this year, Redox achieved certification with FAMI-QS after being certified by DNV Business Assurance Australia Pty Limited.

What is FAMI-QS?

The ultimate goal of this Code of Practice is to ensure feed safety by minimising unsafe practices and the risk of hazardous ingredients entering the food chain. Animal feed is considered unsafe for its intended use if it is likely to pose a risk to (has adverse effect on) human or animal health, or if the food derived from food-producing animals is unsafe for human consumption.

The FAMI-QS code of practice provides requirements for implementing measures necessary to ensure animal feed safety and quality of products manufactured by processes, as defined by FAMI-QS. The code covers requirements on good manufacturing practices, on the HACCP programme and suggestions on continuous improvements to the design, management of operations and risks with a goal of maintaining feed safety and quality.

The scope of FAMI-QS is specialty feed ingredients. A specialty feed ingredient is defined as any intentionally added ingredient, not normally consumed as feed by itself, whether or not it has nutritional value, which affects the characteristics of feed or animals/animal products and animal performance.

The Feed Chain Activities covered by FAMI-QS are Production – The processes and methods used to transform tangible inputs (raw materials, semi-finished goods) and intangible inputs (information, data) into goods and Trade – The action of buying, handling, storage, transporting and selling goods and services.

For more information on production processes covered by FAMI-QS certification, please read more here.

Exciting news from one of our partners, Tessara, as they have officially launched two new products at Asian Fruit Logistica Bangkok. Two new sulphur pad products for table grapes, called Uvays Vivo and Berrisys, for the blueberry industry which extends the shelf life of blueberries during storage and transportation.

Read more below about this exciting launch.

Tessara manufactures sulphur dioxide laminated sheets (sulphur pads); the company specialises in fresh science by providing post-harvest solutions that maximise the shelf life of valuable fresh produce to minimise food waste.

“Our sulphur dioxide laminated sheets are scientifically designed for individual crops: table grapes, blueberries, raspberries, blackberries and cut flowers.”

Tessara’s production facility is BRC accredited with an AA rating and operates 24/7, 5 to 7 days a week. They have approximately 200 staff, including representatives and agents in key markets in Asia, Africa, Europe, Australia, and North and South America. Tessara offers an innovative range of products that increases the shelf life during post-harvest storage and transportation.

“…Our focus is about keeping fresh produce fresher for longer.”

“Our sulphur dioxide laminated sheets are scientifically designed for individual crops: table grapes, blueberries, raspberries, blackberries and cut flowers. All our products are for post-harvest application; they sterilise the fruit and destroy fungal pathogens, mainly Botrytis cinerea, a common cause of post-harvest rot during storage. Our focus is about keeping fresh produce fresher for longer.”

Tessara’s range of products includes UVASYS and UVASYS VIVO, the fully recyclable sulphur pad for table grapes. In addition, BERRISYS and BERRISYS LITE are for berries – blueberries, raspberries, blackberries, and FLORASYS– for cut flowers.

“A smart change in your post-harvest system can significantly affect your valuable crop’s shelf life. We enjoy discussing everything post-harvest to maximise shelf life.

Both products are available and used in South Africa and the UK, with Turkey and Georgia following suit. In Australia, the APVMA registration for Berrisys is pending for December 2022. We eagerly await this approval to assist the Australian industry with its exports and domestic market opportunities for APVMA registration. Stay tuned and contact us if you have any questions regarding this exciting new product.

The importance of water is often overlooked in our modern world. National Water Week, hosted by the Australian Water Association (AWA), hopes to encourage individuals and communities to be inspired by how much we need this essential resource for life!

Difficulties in managing this precious resource are as varied as they are complex. Australia’s climate and landscape, coupled with the demands of agriculture and growing urban populations, can make water supply difficult. Northern Australia, for example, has significant water resources that are not easy to capture and store.

Add to this,

- Professional skills shortages

- Bushfire contamination

- Sewage and wastewater

The Australian Water Association is the most extensive not-for-profit network dealing in all aspects of water, including inspiring and driving a sustainable future for our country’s precious resource – fresh, clean drinking H2O! Through local, national and international networks of individual and business members, AWA shares information and opportunities to inspire positive change by sharing expertise.

How can Redox help?

Redox has a proud tradition of supplying quality water treatment products to all areas of the industry, reaching back more than fifty years. We know that innovation, safety, efficiency and dependability are paramount in treating one of the world’s most precious resources.

Our wide range encompasses items for use in all aspects of water treatment, from pH adjusters for potable drinking water, speciality biocides for cooling towers, Ion Exchange for power stations, and great-value pool chemicals. For the safest and cleanest water, we supply:

- Flocculants

- pH adjusters

- Fluoridation additives

- Organophosphates and biocides

- Filter media

- Scale inhibitors

- Coagulants

- Ion Exchange Resins

Browse our full water capability statement below or click here to download a copy.

Redox has been a member of the AWA for many years and has specialists in water treatment and filtration who can assist when you aren’t sure what to do. Whether it be floods, droughts or desalination, Redox is here to support our customers’ needs. Contact one of our specialists today to find out more.

Did you know that Hydrochloric Acid is also known as HCL, muriatic acid, or spirits of salt? It’s utilised in a variety of industrial and commercial settings. For those who work in industries that use this chemical, it’s vital to understand the most common applications, what they accomplish, and what you need to know to handle them safely and responsibly.

What Is Hydrochloric Acid?

Hydrochloric Acid is an odourless, colourless solution of hydrogen chloride in water with a pungent smell. But behind this almost invisible veneer lies a powerful punch. For instance, Hydrochloric Acid can react with metals to form an explosive gas. Yet, it can also be found in many home cleaning products.

1150 kg IBCs housed in our warehouse, classified Hazard Class 8, are for corrosive materials, defined as substances that can cause significant harm to living tissue and/or corrode steel and aluminium if they leak.

Hydrochloric Acid is classified as a class 8 hazardous product, i.e. it’s a corrosive substance and can cause burns and irritation to the skin. Due to its corrosive properties, extreme care must be taken when handling this product. Make sure to wear appropriate safety equipment when handling hydrochloric acid. Ensure to avoid direct eye contact; if this occurs, seek immediate medical advice.

We recommend you consult the safety data sheet when using, storing or handling the product.

Hydrochloric Acid in the market and its many uses

This potent acid is found in many industries and has a wide range of uses.

What is Hydrochloric Acid used for?

The most significant end uses for Hydrochloric Acid are cleaning, the productions of fertilisers and dyes, steel pickling, oil well acidising, food manufacturing, producing calcium chloride, and ore processing.

How it’s used also varies significantly. For instance, in water treatment, it’s used to control pH levels, or in swimming pools, it can help remove any stubborn algae from the floors and walls of your pool. In acidising oil wells, it helps remove carbonate reservoirs, or limestones and dolomites, from the rock. It’s used in laboratories for acid-base titrations and for producing organic and inorganic compounds like PVC.

We also find substantial use of Hydrochloric Acid across many other industries like:

- Mining,

- water treatment,

- oil/gas,

- detergents,

- leather, building,

- textile,

- rubber,

- photography.

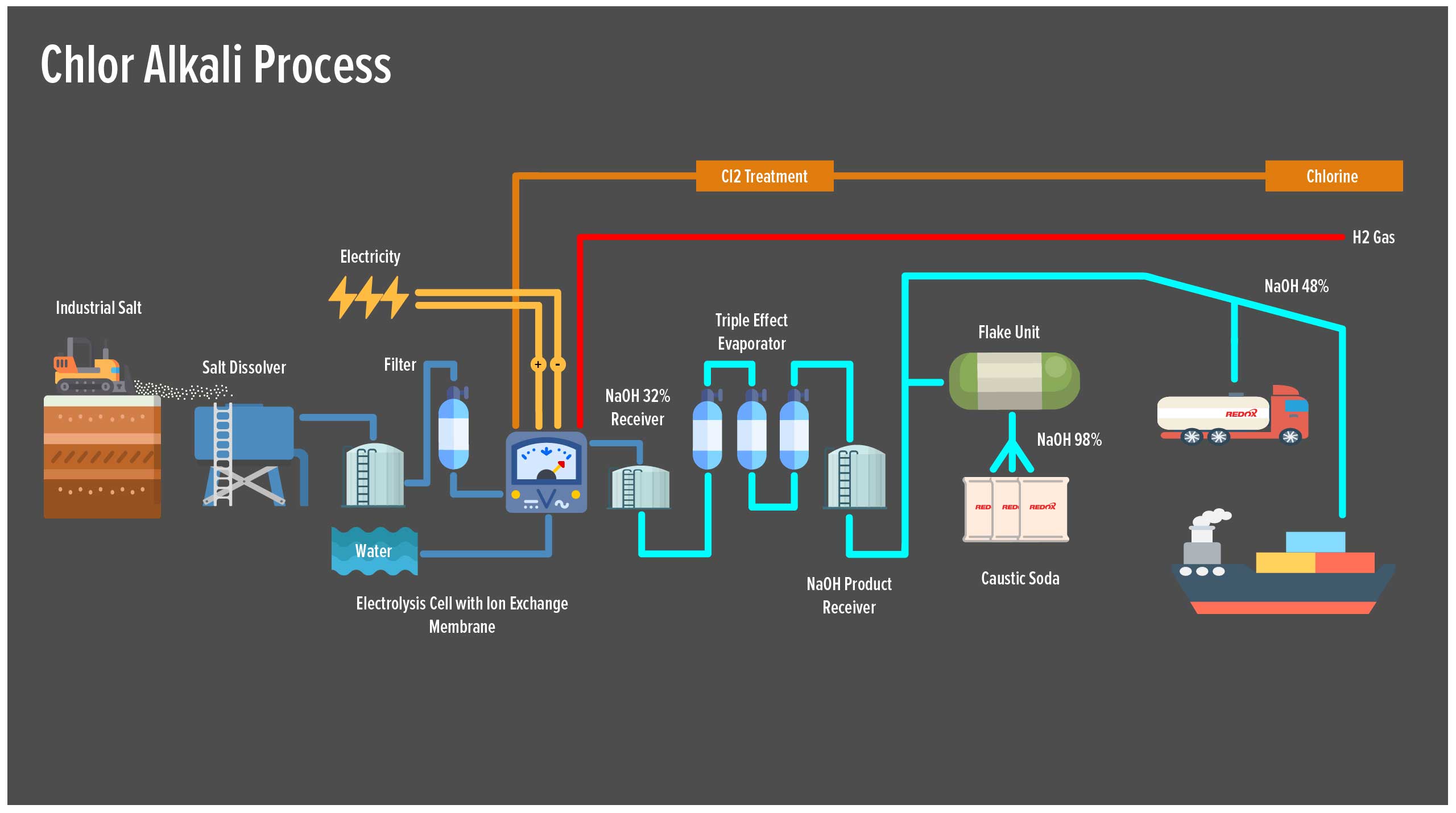

Hydrochloric acid is manufactured predominantly in industrial chlor-alkali plants around the world. The process involves the electrolysis of sodium chloride (salt) solution . This produces chlorine gas , sodium hydroxide and hydrogen gas. The hydrogen is then used to produce hydrochloric acid and ammonia.

In 2020 the global Hydrochloric Acid market size was US $7.8 billion and was expected to record a revenue CAGR of 1.5% over the forecast period through 2028.

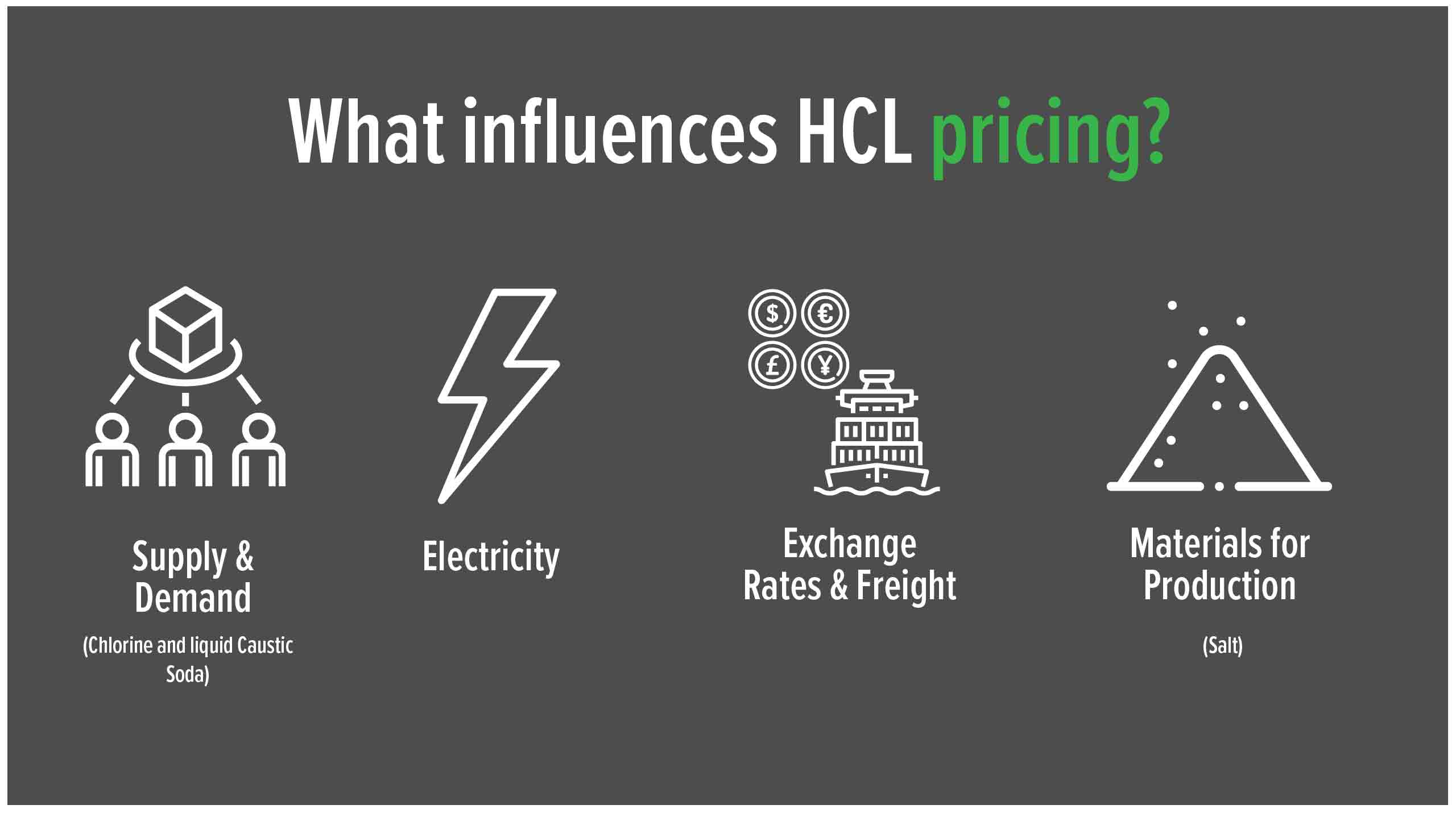

HCL prices are usually fairly stable and tend to increase yearly as a result of CPI increases, usually as a result of the cost of production (labour /electricity costs etc). However, the imported cost of the product is highly dependent on exchange rate variations, packaging and sea freight costs. Finally the overall economics of supply and demand would also play a role in the change in the price of HCL, which is also dependent on Chlorine and liquid Caustic Soda demand, which are all part of the chlo-alkali process.

Hydrochloric Acid In The Home

In the home, you’re most likely to find it used in cleaning agents like toilet and tile cleaners, as it removes grime without reacting to many bathroom surfaces.

Is Hydrochloric Acid Corrosive?

In short, yes. Hydrochloric Acid is corrosive to organic tissues and will corrode mucous membranes, eyes, skin. It can also be corrosive to almost all metals.

How can we help you?

Redox’s Hydrochloric Acid is available in various pack sizes, including 20-litre carboys, 240 kg drums, 1150 kg IBCs and bulk tanker/Isotainers loads. The product comes in a range of strengths ranging from 6% to 33%, with 32% hydrochloric acid being the main commonly used strength.

Contact one of our experts to discover how Redox can be essential to your sourcing strategy.

Dextrose is the name of a simple sugar mainly derived from grains such as corn or root plant. Find out how Redox can become integral to your Dextrose sourcing strategy.

What is Dextrose & how is it used?

Dextrose is used in many products because it has several beneficial effects and is widely available. Its often used as a sweetener or preservative or to neutralise food that is too spicy or salty. It has a high glycaemic index, increasing blood sugar levels quickly and is an excellent source of energy.

It’s frequently used and commonly found in the below food items:

- Sauces

- Seasoning mix

- Chips

- Cured meats

- Canned foods

- Pickles

- Crackers

- Fruit jams

Dextrose added to cured or processed meat to counteract intense saltiness of cured meat and as a medium (food) for the microbial fermentation process used to reduce the pH of dry and semi-dry sausages.

Our Dextrose can also be used in animal feed /pet food and various industrial usage; however, they are more commonly used in confectionery, beverages, dry mixes and meat treatment because it adjusts sweetness and refreshes taste.

Does it have medicinal applications?

Dextrose is periodically prescribed by doctors alone or combined with other medications. It’s usually administered either intravenously or orally. It can be used to treat low blood sugar and dehydration, as well as to provide nutrition.

How can we help?

Our Dextrose is a non-GM product, available in both Monohydrate and Anhydrous variants and meets rigorous standards while retaining its authentic essence and taste. It is available in 15-25kgs bags and 800kgs bulk bags, which we routinely supply to our customers around the globe.

Redox is in a great position to meet and surpass your expectations. So contact one of our specialists by filling in the below form and have one of our team get in touch with you.

Our Partnering Manufacturers