Molds are filamentous fungi that occur in many feedstuffs including grains and forages. Molds can produce mycotoxins that are formed on crops in the field, during harvest, or during storage, processing, or feeding. The mycotoxins of great concern include aflatoxin (Afla), deoxynivalenol (DON), zearalenone (ZEN), T-2 Toxin (T2), and fumonisin (FUM).

Traditionally, maize was easily contaminated by mycotoxin. However, in a recent survey, 71% wheat samples were contaminated by DON in Australia. Therefore, the routinely use of mycotoxin binders may help ruminant animal to avoid exposure to low levels multiple mycotoxins, considering that these binders could bind mycotoxins strongly enough to prevent mycotoxin absorption across the digestive tract.

Maize has long been known for its susceptibility to mycotoxin contamination. Surprisingly, a recent Australian survey found that 71% of wheat samples were contaminated with deoxynivalenol (DON).

Potential binders include activated carbon, bentonite, zeolite, diatomaceous, earth, cellulose, yeast cell wall polysaccharides, and synthetic polymers such as cholestyramine and polyvinylpyrrolidone.

Activated Carbone: it is a general adsorptive material with a large surface area and excellent adsorptive capacity. It is routinely recommended for various digestive toxicities at 30-50 g per day per cow. previously, it was suggested that Activated Carbone may not be as effective in binding Afla as bentonite or zeolite. However, in a recent in vito trial, it shows an overall better adsorption capacity except for T2 with the lower adsorption capacity.

Bentonite: it is a hydrated sodium calcium aluminum magnesium silicate hydroxide and usually is used as anti-cake agent at 1 to 2% of cattle diets. Based on the recent in vitro trial, it only shows higher adsorption capacity for Afla.

Zeolite: adding 250 to 500 g zeolite per day per cow has been approved to prevent ‘milk fever’. In a recent in vito trial, it also shows a similar adsorption capacity for Afla, T2, and Zen.

Diatomaceous earth: it is usually used as an insecticide on stored cereals and storage rooms. 1% to 2% feed grade diatomaceous earth has also been recommended to add to cattle feed to reduce internal and external worm or parasites. Diatomaceous earth has also shown the potential in vitro to bind Afla.

Yeast cell wall polysaccharides: the outer layer of the cell wall constituted with glucomannan and mannon proteins that determine the superficial properties of the yeast cell wall. The adsorption capacity increases as the proportion of β-D glucans present in the yeast strains increases. However, in a recent in vitro trial, the yeast cell wall product for this trial showed the much lower adsorption capacity compared with the activated carbon.

In general, these mycotoxin binds are helpful to reduce the biavailability of mycotoxin. However, it is difficult to select the appropriate adsorbent for each mycotoxin.

A study compiled by our Redox Animal Nutritionists.

Yeast supplements include live yeast, yeast cell wall (YCW), purified outer layer of cell wall components such as mannooligosaccharide (MOS) and β-glucans, purified inner layer of cell wall, and yeast extract products. It is generally accepted that yeast products can improve pig gut health via improved gut integrity and maintenance of a healthy microbiome, leading to increased nutrition absorption, and thus improved overall pig performance.

Live yeast refers to yeast cells that are still alive and active. It is often used to improve digestion and promote gut health for ruminant animals.

After autolysis (using the yeast’s own enzymes) or hydrolysis (using added exogenous enzymes), the yeast extract and cell walls are separated using centrifugation before being dried. Usually, the yeast extract via autolysis contains higher levels of yeast nucleotides. However, the yeast extract via hydrolysis is more applicable due to a low salt concentration.

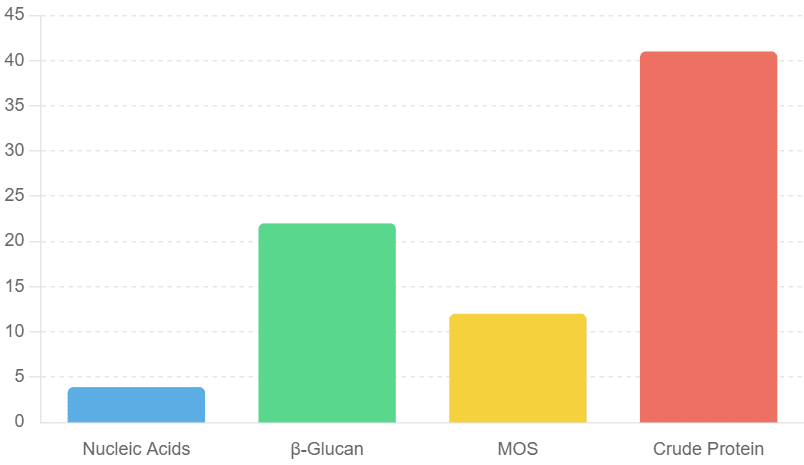

The composition of autolyzed yeast (AY)

The composition of autolyzed yeast (AY) has been summarized as 3.5-3.9% nucleic acids, 11-22% of β-glucan, 3-12% MOS, and 30-41% crude protein. Adding 0.2-0.5% AY to pig diets could improve the performance and immune function of weaned and finished pigs.

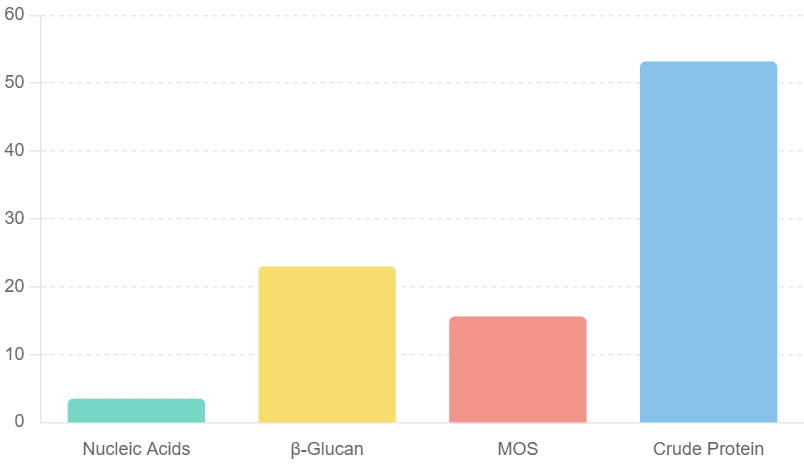

The composition of hydrolysed yeast (HY)

The composition of hydrolysed yeast (HY) includes 3.5% nucleic acids, 22.43-23% β-glucan, 15-15.6% MOS, and 40-53.2% crude protein. The effective inclusion rates of HY in diets for the weaned, grower, and finisher periods are 0.1-0.2%, 0.05-1.0%, and 0.1%, respectively.

The yeast cell wall fraction is mainly composed of polysaccharides, making up 15 to 30% of the dry weight of the whole cell. The inner layer of the cell wall mainly contains β-D-glucans which is used as the organic mycotoxin binder. Supplemental levels of the mycotoxin binder are recommended around 0.1 to 0.2%

The outer layer of the yeast cell wall is made of MOS and β-glucans. Adding purified β-glucan to early weaned piglets dets showed protective effects against E Coli infection by reducing bacterial excretion and diarrhoea. The recommended dosage of β-glucan is 100-200 ppm or 100 -200 g/MT feed. The purified MOS can attach the bacterial surface, and then protect the colonization of bacteria in the intestinal tract. Supplementation of MOS in the range of 500 to 1000 ppm or 500 g to 1 kg /MT feed.

In addition, approximately 1-20% of total nitrogen in yeast are derived from nucleic acids. Nucleotides are significantly required by cell replication process, particularly intestinal epithelial and lymphoid cells. Nucleotides are also important in immune system maintenance and prevent oxidative stress. The purified Nucleotide inosine monophosphate (IMP) is commercially available and recommended supplemental levels are ranged 500 ppm to 1000 ppm or 500 to 1000 g/Kg feed.

A study compiled by our Redox Animal Nutritionists.

Yucca schidigera is an herbaceous plant of lily family, native to the deserts of the southwestern United State and northern Mexico. It contains two active compounds: at least 10.5% steroidal saponins and polyphenols. Saponins are similarly in structure to Glucocorticoids in animals.

Previously It was thought that the Yucca extract could bind ammonia and therefore reduce its emission from pets and other animals. However, ammonia concentrations in the gut are at least 100-fold greater than the concentrations of the yucca extract. Currently it is believed that the high circulating levels of Glucocorticoid in response to various oxidative stress including heat stress result in enhanced degradation of amino acids to generate ammonia and reduced protein synthesis in skeleton muscle.

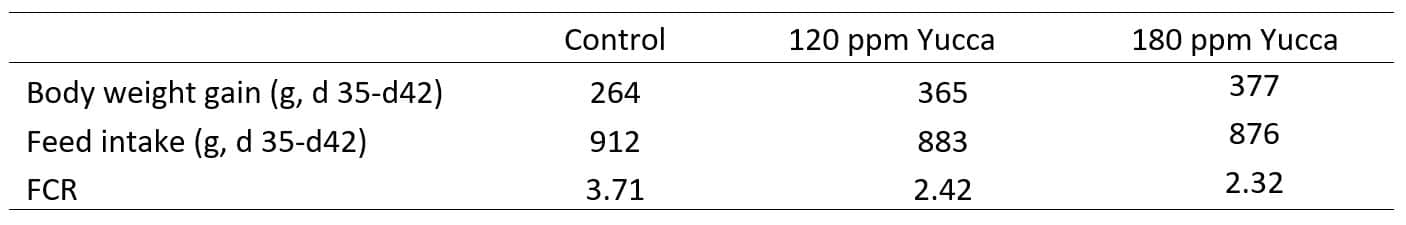

Under conditions of the oxidative stress including heat stress, the Yucca extract can block the bonding of glucocorticoids to their receptors in cells. Thus, the yucca extract could alleviate the oxidative stress including heat stress and reduce ammonium emission in the stress situation (Table 1). When broiler chickens were housed at an average ambient temperature of 24˚C, dietary supplementation of Yucca extract (120 ppm and 180 ppm) did not affect the feed intake or body weight gain (Wu, 2018). However, in table 1, when the ambient temperature was naturally elevated from 27˚C to 37˚C, the Yucca supplementation improved body weight gain by 38-43% and FCR 46% to 52% compared with the control group.

Table 1 The effect of the addition of the Yucca extract on broiler chicken performance under the heat stress

Yucca saponins also have anti-protozoal activity by supressing protozoal infection of the intestine. It is reported that Yucca saponins could bind with cholesterol in protozoal cell membrane and destroy the integrity of the protozoal membrane. Coccidiosis is one of the main challenges for the worldwide poultry industry. Although coccidiostats are often rotated, the poultry industry is challenged by resistance of the Eimeria parasites to these treatments. In a recent trial conducted in the Europe, Kozlowski et al (2022) reported that both the anticoccidial and 500 g/Mt Yucca supplementation showed significant improvement in body weight (2150 g and 2058 g vs. 1998 g, Table 2)

It is now also reported that Yucca polyphenolics have anti-inflammatory activity and could prevent arthritis. The generation of reactive oxygen species such as nitric oxide is an important factor in the development of rheumatic arthritis. Yucca polyphenolics may inhibit nitric oxide production and prevent arthritis.

Table 2. The effect of supplemental Yucca extract on challenged chicken performance (d1-35)

A study compiled by our Redox Animal Nutritionists.

It is well known that in the current floor pen with deep litter system, day old broiler chickens could benefit from non-starch polysaccharides components in the litter to establish the dynamic microbiota. However, when the intestinal microbiota becomes complex and diversified over time and environmental conditions, long term exposure to faeces and ammonia pollution environments has a higher risk of infection with pathogenic bacteria and parasites.

For decades, chicken enteric disease including necrotic enteritis (NE) and coccidiosis have been controlled by using antibiotic growth promoters (AGP) and coccidiostats. However, due to the development of antibiotic resistance in bacteria and coccidiosis, which is a threat to animal and human health, the use of AGP and coccidiostats has been restricted or banned in the poultry industry. Thus, alternatives production strategies including vaccinations, organic acids, prebiotics, probiotics, essential oils, postbiotics or yeast peptides to control NE and coccidiosis have been explored.

The Glucose Oxidase (GOD) is exogenously produced by specific fungi fermentation to oxidize β-D-Glucose into gluconic acid and hydrogen peroxide, consuming large amounts of oxygen at the same time in the chicken gut. Therefore, it can protect against oxidative stress and directly kill some pathogenic bacteria or Eimeria parasites. Gluconic acid is a kind of organic acid, which acts as an acidifier in the intestine to produce the short chain fatty acids such as butyric acid. GOD also plays an important role in colour development, flavour, texture, and increasing the shelf life of food products. Due to its characteristics of producing natural acid, deoxygenation and sterilization, GOD has been defined in AAFCO list as 70.3 and widely used in animal production.

Recently, the University of New England (UNE) conducted a NE challenging trial to investigate the GOD potentials to ameliorate the impact of NE on chicken performance and intestinal health. The standard, positive controls (PC) were formulated based on wheat-sorghum-soybean meal as the commercial diets. Negative control (NC) chickens were challenged with Eimeria parasites at day 9 and clostridium perfringens at day 14. Another 4 treatments consist of PC or NC diets supplemented with antibiotics, GOD 100 g/MT, 200 g/MT and 300 g/MT, respectively.

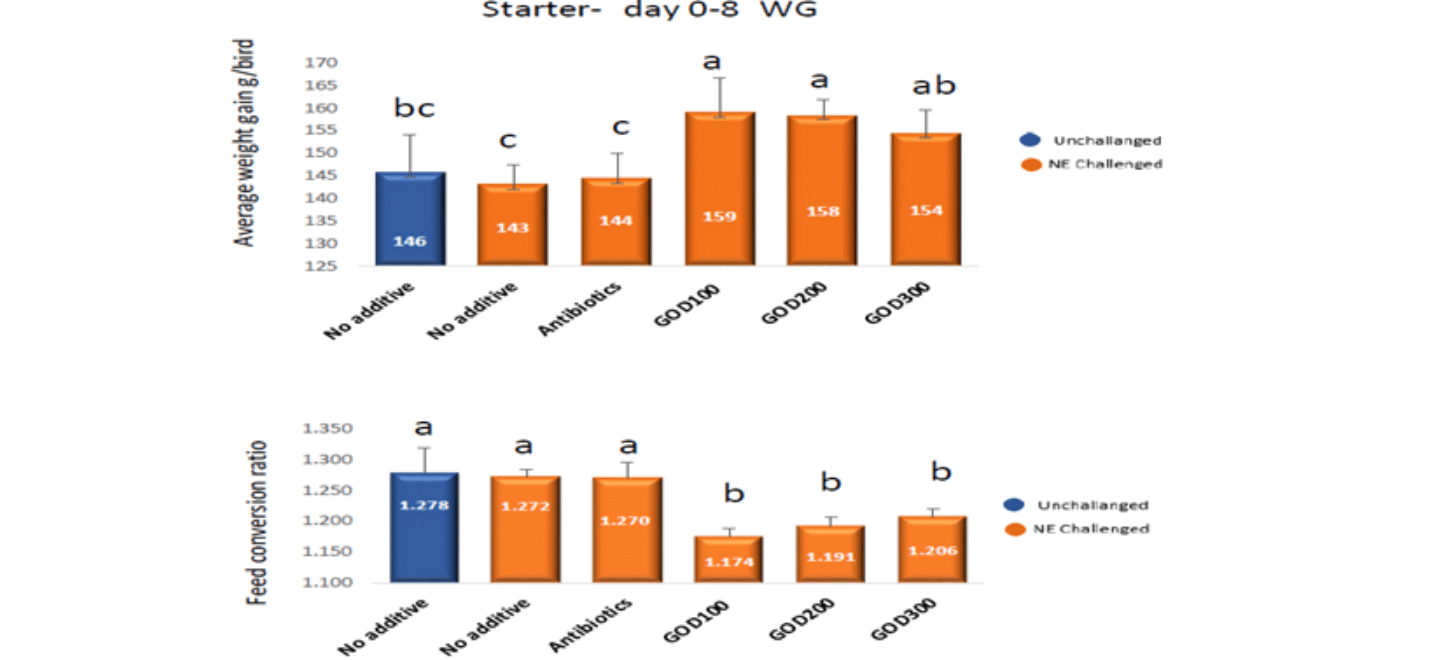

The effect of GOD on chicken performance before challenging was shown in Figure 1. It is clearly shown that adding GOD significantly improved chicken body weight gain by 9% and FCR was improved by 10 points. From the growth point of view, AGP supplementation did not show any impact on chicken body weight gain and FCR.

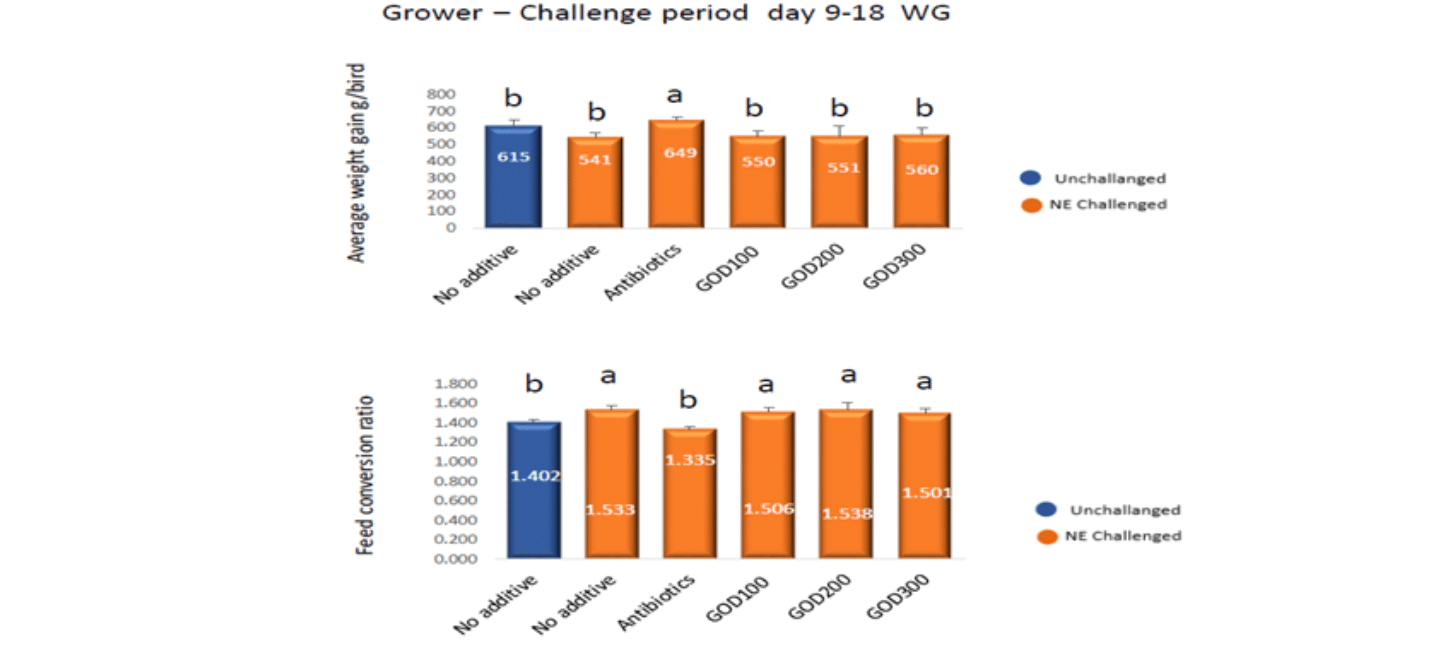

However, during the challenging period (Figure 2), AGP significantly improved the chicken body weight gain and FCR compared with the positive control. Interestingly, during the recovery period (Figure 3) or chickens had the longer-term exposure to faeces and ammonia pollution, chickens in positive control and supplemented with the lowest GOD showed worst performance, but chickens in the negative control showed the best performance, possibly due to that Eimeria challenged birds boomed their immune system for the possible coccidiosis infection. It might also imply that supplementation of GOD could replace both coccidiostat AGP.

However, the lower level of GOD might have the negative effect of Eimeria vaccination.

Figure 1. The effect of GOD on chicken performance before challenging.

Figure 2. The effect of GOD on chicken performance during challenging.

Figure 3. Efeect of GOD on chicken body weight gain after challenging period (d 28-35)

A study compiled by our Redox Animal Nutritionists.

Rumen microorganisms can utilize non-protein nitrogen (NPN) such as ammonia to synthesis rumen microbial proteins for cattle and sheep. Urea is a cheap source of NPN but the hydrolysis rate of urea in the rumen is speedy and exceeds the ammonia utilisation rate of rumen microorganism. Surplus ammonia is harmful to the animal and is also associated with increased methane production. Coated urea is designed to provide a controlled release of urea in the rumen, allowing for a more efficient utilisation of nitrogen by rumen microbes.

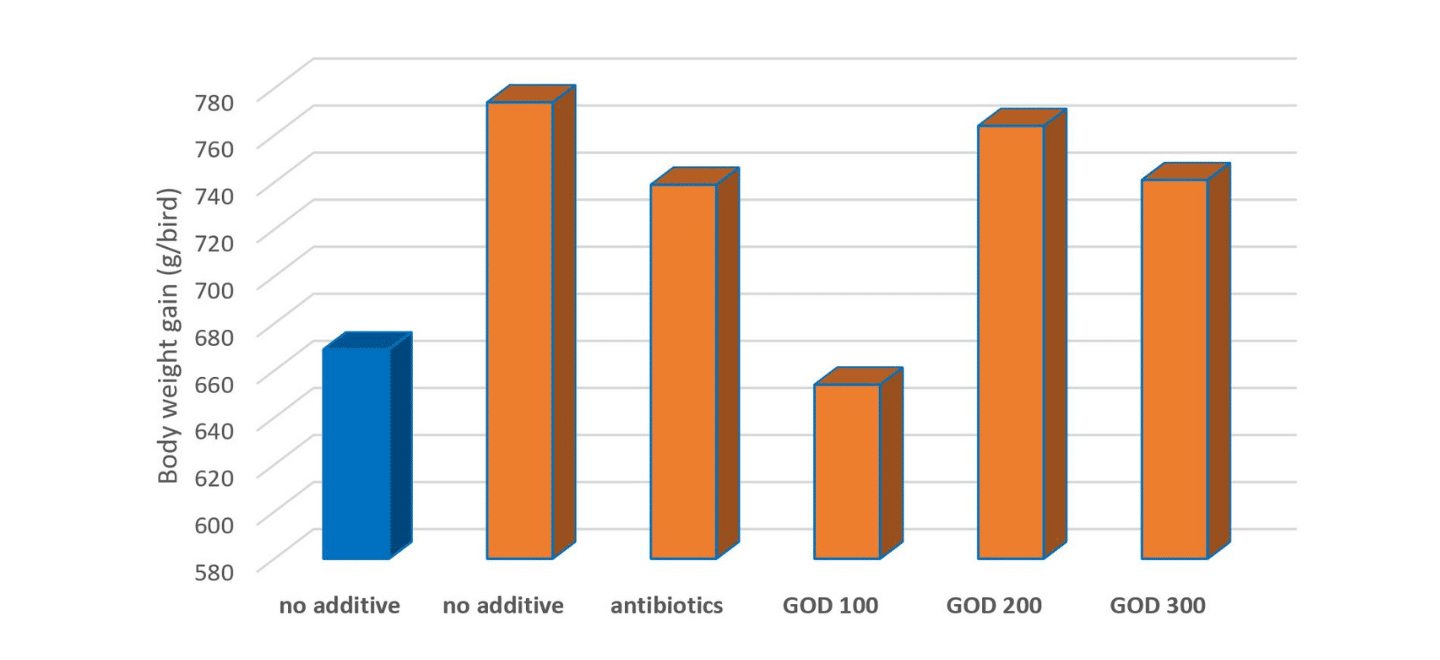

In Figure 1, it is clearly shown that compared with Menogen plus (the coated urea), normal urea is almost completely degraded within 20 minutes. On the other hand, the degradation rate of soybean meal or canola meal is too slow. Within 8 hours, the degradation rate of soybean meal and canola meal is about 50% and 30%, respectively, considered as the good source of rumen undegraded protein.

However, less ammonia concentration may not provide sufficient nitrogen source for rumen microorganisms to effectively synthesise rumen microbial protein. Therefore, addition of the coated urea could provide stable nitrogen supply for rumen microbes. It is reported that providing 90 grams coated urea per day per cow could replace 450 grams soybean meal and increase milk production by 0.85 kg per day per cow.

Figure 1. The degradation rate of different nitrogen sources in Rumen

In summary, this controlled release urea can lead to several benefits in terms of methane reduction and overall animal nutrition:

- Reduced ammonia levels:

The coated urea undergoes gradual hydrolysis in the rumen, releasing ammonia at a controlled rate. This controlled ammonia release ensures a stable nitrogen supply for rumen microbes, reducing excess levels. High ammonia levels in the rumen are associated with increased methane production.

- Improved microbial protein synthesis:

The coated urea supports the growth of rumen microbes by providing a steady and controlled supply of ammonia. These microbes are responsible for breaking down fibrous materials and producing microbial protein. Efficient microbial protein synthesis can lead to improved feed digestion and reduce d methane emissions.

- Optimised nitrogen utilisation:

The coated urea allows for better synchronisation between available nitrogen and microbial needs. This synchronisation can lead to improved utilisation of dietary protein and reduced excretion of nitrogen in the form of urea. Lower nitrogen excretion can contribute to reduced ammonia levels and subsequently, reduced methane production.

- Balanced rumen environment:

The coated urea helps in maintaining a stable rumen PH and stable pH conditions are conductive to the growth of specific microbes that produce less methane during feed digestion.

- Increased fibre digestibility:

Improved microbial efficiency and balanced rumen pH can enhance the digestion of fibrous materials. Enhanced fibre digestion results in fewer substrates available for methane-producing microbes, leading to reduced methane emission.

A study compiled by our Redox Animal Nutritionists.

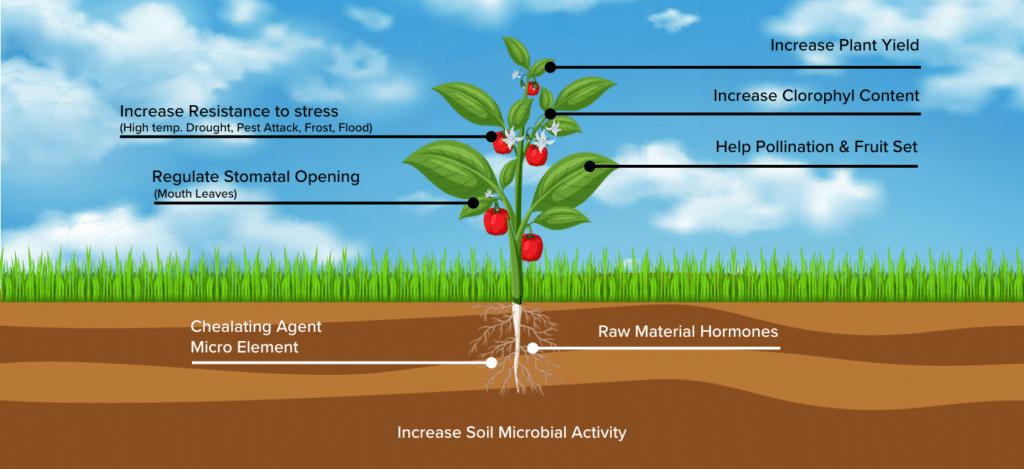

In the world of agriculture, the battle for survival against nature’s forces is relentless. Factors such as light deficiency, water scarcity, pests, diseases, salinity, wind, and phytotoxicity continually challenge the resilience of plants. To aid in this ongoing struggle, Redox, in collaboration with CJ Bio, introduces AMIBOOST® —a high-quality biostimulant enriched with specialized amino acids. This remarkable product is meticulously designed to bolster crop yield and quality, addressing the needs of various plant types and growth stages. These amino acids act as catalysts for the plant’s secondary metabolism, a vital part of its immune system, enabling plants to thrive even in the face of adversity.

But surviving under stress is not the epitome of plant health. Instead, the plant has to divert its resources from primary metabolism, which deals with growth and development, to cope with these challenges. This is where amino acids come into play as an essential tool to bolster the plant’s defences and recovery mechanisms. They act as biostimulants that can make all the difference in a stressful situation.

Recognising that it wouldn’t be a single front of management that would solve this battle. To effectively combat stress, amino acids should be part of a broader strategy. This strategy should include factors like soil fertility management, pest and disease control, and proper irrigation, all of which contribute to a plant’s overall health and reduce stress. And an inclusion of Amino acids serves as a boost in these challenging situations.

However, not all amino acids are created equal in this plant kingdom, and the “L-amino acids” are the superheroes. Each amino acid has a unique role in this intricate world of plant survival, combating biotic and abiotic stressors.

Introducing the future of agricultural excellence: The latest innovation, Amiboost ROOT, Amiboost DEVELOPMENT, and Amiboost HARVEST. AMIBOOST’s superior biostimulants redefine crop yields, whether you’re cultivating grains, fruits, or vegetables. Crafted to harmonize with your local environment and quality standards, this revolutionary product ensures convenience for sellers and satisfaction for their customers. Elevate your crop with Amiboost – the key to unlock exceptional performance.

Understanding Plant Stress

The term “plant stress” encompasses various factors that disrupt a plant’s normal functions. These can range from insufficient light, water scarcity, salinity, strong winds, phytotoxicity, and pest and disease attacks, hindering a plant’s total development.

Plants employ two metabolic strategies: primary and secondary metabolism. Primary metabolism is associated with growth, including plant development, root and leaf expansion, and photosynthesis activity. In contrast, secondary metabolism acts as a plant’s immune system, a survival mechanism for adverse conditions.

Enduring stress at the metabolic level isn’t healthy for plants. To thrive, they need to adjust their primary metabolism and activate secondary metabolism. This is where amino acids come into play as essential tools.

The Role of Amino Acids

Recognising that plant stress doesn’t arise from a single source is crucial. To effectively combat stress, amino acids should be part of a broader strategy. This strategy should include factors like soil fertility management, pest and disease control, and proper irrigation, all of which contribute to a plant’s overall health and reduce stress. Amino acids serve as a valuable bio-stimulant in these challenging situations.

Plants rely on proteins as they are the basic constituents of all living cells. First, it’s important to highlight that protein is formed by combining different amino acids; about 20 crucial amino acids can help plants grow accurately.

How does it happen? So, plants synthesise amino acids from the carbon and oxygen obtained from air and hydrogen from water in the soil, forming carbon hydrate through photosynthesis and combining it with the nitrogen the plants obtain from the soil. As a result, the synthesis of amino acids. L-Amino Acids are part of these proteins and have metabolic activity, including hormone and enzymatic functions, structure building, immune response, nutrient transport, etc.

However, an adverse situation can occur, and the plant cannot generate these important amino acids efficiently. Hence, feeding your plants L-amino acids makes them perform these functions efficiently and better, consequently minimising negative stress.

In this way, if the 20 amino acids can be directly supplied, it will help to overcome the limitations caused by plant stress.

The type of amino acid must be considered; products should contain L-amino acids, Laevorotatory amino acids, or L-amino acids, as those are the ones that plants can assimilate.

The Significance of Amino Acids in Plant Metabolism

Plants naturally synthesise about 20 amino acids that are indispensable for their metabolism. Think of these amino acids as the oil in a car engine. Just as a car needs the right type and quantity of oil to function correctly, plants require specific amino acids for their well-being. Without these amino acids, plants may require intervention to thrive.

Each phase of a plant’s development demands specific types and quantities of amino acids. Using amino acids at the right time physiologically activates a plant’s metabolism, promoting its growth.

By understanding the significance of different amino acids and how they function, we can better support plant growth, even in challenging conditions.

Understanding Biotic Stress

Biotic stress in plants results from pest and disease infestations within crops. What renders a plant susceptible to these attackers is its production of sugars and compounds that serve as a food source for them.

Amino acids like Tyrosine, phenylalanine, and tryptophan play a vital role in this scenario. They are directly linked to producing phenolic compounds in a plant’s secondary metabolism. These phenolic compounds act as natural defence mechanisms, functioning like antibodies that thwart disease development and make the plant’s sap less appealing to pests.

Plants Under Abiotic Stress

In the face of abiotic stress, compounds like Folcysteine come to the plant’s rescue. Folcysteine is a derivative of the amino acid cysteine, and its primary function is to counteract free radicals, reducing oxidation. This is especially crucial because Folcysteine serves as a sulphur source and contributes to the synthesis of glutathione, a vital molecule in a plant’s defence system.

Proline plays a pivotal role in mitigating the effects of stress, particularly when it comes to hydric (water) and saline stress. It’s an amino acid renowned for its association with drought resistance, functioning as an osmo-protective agent, similar to arginine. Proline stabilises the plasma membrane, preventing structural damage, such as weakening the cell wall, especially during conditions like excessive temperature increases or water scarcity.

Abiotic stress in plants refers to the negative impact of non-living factors or environmental conditions on plant growth, development, and overall health. Unlike biotic stress, which is caused by living organisms such as pests and pathogens, abiotic stress factors are non-living and typically relate to various environmental factors.

Glycine is a crucial player in chlorophyll composition, facilitating the process of photosynthesis. Additionally, it assumes a critical role in maintaining the plant’s internal osmotic balance. Glycine is often accumulated in plants facing various stressors like excess water, salinity, cold, heat, and freezing conditions, as it actively contributes to upholding the integrity of cell membranes, thereby sustaining photosynthetic efficiency.

Addressing Phytotoxicity in Plants

These damages impair the normal development of plants, as they are mostly related to the interruption of production or distribution of photoassimilates. Injuries prevent the leaf from carrying out photosynthesis and can be a factor in loss of productivity. Amino acids are essential allies to minimise these harmful effects and encourage plants to recover their photosynthetic capacity.

Being small molecules quickly absorbed, they begin to act on metabolism in a few hours, transporting toxic elements and promoting the restoration of regular cellular activity in plants.

Heavy metals from the soil or in formulations used in crop management, nutritional elements in excess or with a high salt content, are examples of agents that cause phytotoxicity.

Histidine is an effective amino acid in complexing heavy metals such as cobalt, nickel, zinc, and copper.

Again, glycine is an essential amino acid in the composition of chlorophyll, and the isoleucine and glutamic acid in the growth of meristems, which are new tissues.

Roles of some amino acids in Adverse Situation.

- Aspartic Acid: It is a nitrogen source essential for producing other amino acids.

- Glutamic Acid: This amino acid plays a crucial role in the growth of meristems, the plant’s new tissues. It also serves as a precursor for chlorophyll and other amino acids since it carries nitrogen sources.

- Alanine: Alanine actively participates in the formation and germination of pollen grains.

- Arginine: Arginine offers resistance to drought, acting as an osmoprotectant. It is also involved in photosynthesis, growth, and the transport of nutrients to reproductive complexes.

- Cysteine: Cysteine is a pivotal amino acid. In addition to being a source of sulphur, it plays a vital role in synthesising glutathione, a crucial molecule in a plant’s defence system. It also aids in stress tolerance.

- Phenylalanine: This amino acid is closely linked to the production of phenolic compounds in the secondary metabolism of plants. These compounds act as plant defence agents, functioning like antibodies to inhibit disease development and making the plant’s sap less attractive to pests. Phenylalanine is involved in synthesising lignin, tannins, flavonoids, and the formation of salicylic acid.

- Glycine (1st Mention): Glycine participates in the formation of glutathione, phytochelatins, and betaine glycine. Betaine glycine is a compound that accumulates in plants under water-stress conditions, aiding in maintaining photosynthetic efficiency.

- Glycine (2nd Mention): Glycine is also essential in the composition of chlorophyll. It plays a critical role in photosynthesis and in regulating the intracellular osmotic balance of the plant. This amino acid is mainly accumulated in plants under various stressful conditions, such as water scarcity, salinity, cold, heat, and freezing stress, as it helps preserve the integrity of cell membranes and maintain photosynthetic efficiency.

- Glutamate: Glutamate participates in the formation of amino acids like arginine, glutamine, and proline. It also acts as a precursor for the chlorophyll molecule.

- Histidine: Histidine is recognised as the most effective amino acid for complexing heavy metals such as cobalt, nickel, zinc, and copper.

- Isoleucine: Isoleucine plays a role in the growth of meristems, which are new plant tissues. It also contributes to forming other amino acids and pollen grain germination.

- Leucine: Leucine is another amino acid that forms other amino acids and plays a role in pollen grain germination.

- Lysine: Lysine is responsible for regulating pollen grain germination and stomatal regulation. It is also a vital nitrogen reserve in plants and activates chlorophyll.

- Methionine: Methionine is a precursor for ethylene, a hormone that influences fruit maturation. It is also responsible for sulphur incorporation in plants.

- Proline: Proline is an amino acid associated with drought resistance, similar to arginine. It functions as an osmoprotectant and is used by the plant as a defence mechanism against water deficits and heat stress.

- Serine: Serine constitutes enzymes that activate proteins facilitating plant growth and the transport of nutrients in the plant’s sap.

- Tyrosine: Tyrosine is linked to the production of phenolic compounds in the secondary metabolism of plants. These compounds function as plant defence agents, inhibiting disease development and making sap less attractive to pests.

- Threonine: Threonine participates in forming other amino acids and is involved in pollen grain germination.

- Tryptophan: Tryptophan is associated with the production of phenolic compounds in the secondary metabolism of plants. Like tyrosine, it is a defence agent against diseases and pests, making the plant’s sap less appealing. Tryptophan also serves as a precursor for auxin, a root growth hormone, and influences the development of aerial plant parts.

- Valine: Valine plays a role in regulating the growth and maturation of fruits.

These amino acids play a fundamental role in maintaining the health and vitality of the crop.

How can we help?

At Redox, we understand the critical role that amino acids play in plant metabolism and stress management. We are committed to providing top-quality amino acid products that can make a significant difference in the health and vitality of your plants. If you’re interested in learning more about our amino acid products or have any questions regarding their application and benefits, we encourage you to get in touch with us.

Our team of experts is here to assist you in implementing an effective strategy to enhance your plants’ overall health and reduce stress. Contact us today to explore how our amino acid solutions can contribute to your plant’s success. Your plants deserve the best, and we’re here to help you achieve just that.

Article compiled by our Redox Agronomists

Currently most dogs are fed highly processed food that is quite different from canine ancestral diets. Sweeteners are quite often included in processed dog food to mask unpleasant taste or enhance the acceptance of the food.

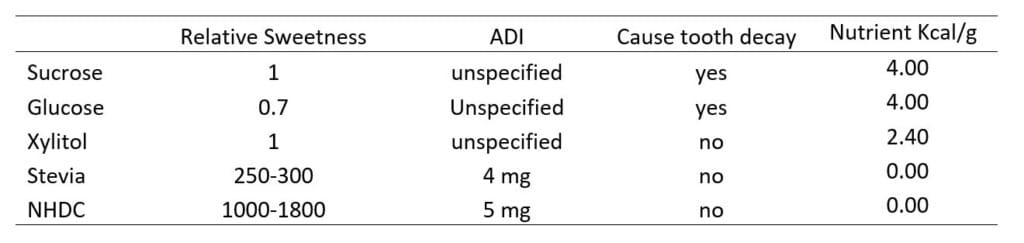

In the recent years, due to health issues, numerous low-calorie sugar free sweeteners have been developed to replace sucrose. Table 1 shows relative sweetness, acceptable daily intake (ADI) of some of some sweeteners.

Table 1 The relative sweeteners and ADI (mg/kg body weight/day) of some sweeteners

It is noteworthy that xylitol will result in fatal reduction in blood glucose levels and the liver failure has been reported in dogs.

Stevia is a sugar substitute made from the leaves of the stevia plant. it is about 250 to 300 times sweeter than sucrose. However, some people complain it is bitter.

Neohesperidine Dihydrochalcone (NHDC) is a sensory sweetener derived from the hydrogenation of Neohesperidine, a flavanone which is found in the immature fruit of bitter oranges. It is about 1000-1800 times as sweet as sucrose. However, commercially available Sugarex containing 10% NHDC is about 150 times as sweet as sucrose and its recommended dosage rates in dog dry food is 50-150 g/MT.

More importantly, all those alternative sweeteners are not effective substrates for plaque bacteria and therefore less likely result in dental caries. However, it is noticed that approximately 50-88% dogs over three years of age have periodontal disease and adding 0.6% sodium hexametaphosphate significantly reduced the area covered by dental calculus. In cats, it is reported that adding 1.2% lactic acid in a maintenance food significantly inhibited oral substrate accumulation.

Adding NHDC to weaning piglets, calf and fish diets also significantly increase the feed intake of young animals.

Report by Redox Animal Nutritionists

It is well known that reduced protein diets in broiler chickens could lessen nitrogen excretion and environmental pollution. However, the successful strategy for broiler chicken production fed on reduced protein diets largely depends on both exact amino acids balance and sufficient quantity.

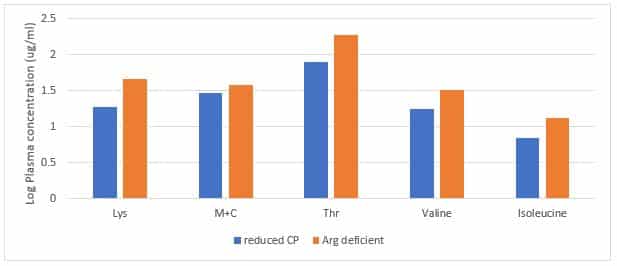

Currently ideal amino acids profile and absolute standardised ileal digestible lysine concentrations provide this recommendation on amino acids balance and quantity, respectively. In reduced protein diets, if any amino acid is deficient or limiting, ingestion of excess of other amino acids will result in accumulation of these amino acids in plasma, leading to the reduction in feed intake. Figure 1 clearly shows that when the reduced protein diet is deficient in Arginine, it will result in increased plasma lysine, methionine plus cysteine, threonine, Valine, and isoleucine concentrations, indicating these surplus essential amino acids could not be degraded for muscle growth.

Figure 1. The effect of Arginine deficiency on plasma amino acids concentration (log ug/ml)

Arginine is one of most versatile functional amino acids because it is a precursor of several molecules, such as creatine, ornithine, nitric oxide, citrulline, proline, and polyamines. Apart from protein synthesis, it can stimulate the release of growth hormone and insulin-like growth factor 1.

Arginine also acts as a trigger of target of rapamycin (TOR) signalling system activation for reducing protein degradation. Supplementation of L-Arginine has been approved significantly increase Nitric oxide and reduce ascites related mortality.

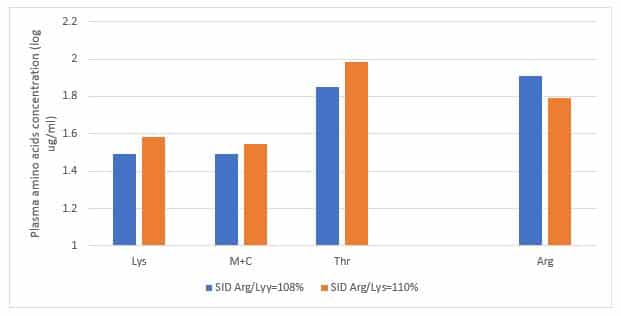

In recent updated amino acids profile recommended by Aviagen breeder company, the SID Arginine to SID Lysine ratio has been increased significantly, up to 110% in the finisher period. A 42 days broiler chicken trial conducted in the University of Sydney clearly showed that when SID Arginine to Lysine ratio increased from 107% to 113%, plasma Lysine, methionine plus cysteine, and threonine concentrations were significantly reduced (Figure 2).

Increasing SID valine to Lysine ratio from 76% to 81%, SID isoleucine to lysine ratio from 69% to 73%, and SID Arginine to lysine ratio from 107 % to 113%, increased breast meat by 59 grams.

Figure 2. Plasma lysine, methionine plus cysteine, and threonine concentrations in response to dietary SID Arg/Lys ratios.

Report by Redox Animal Nutritionists

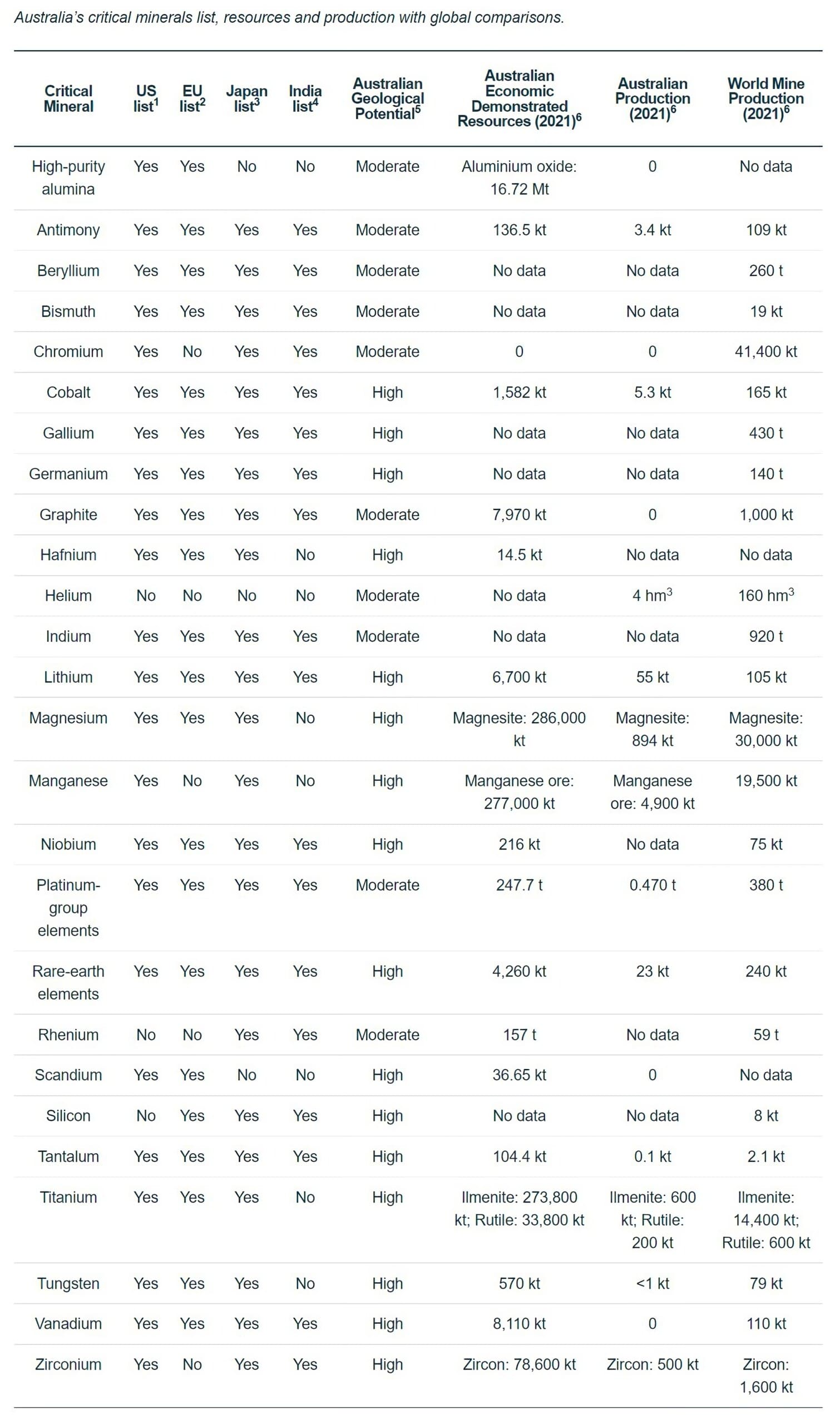

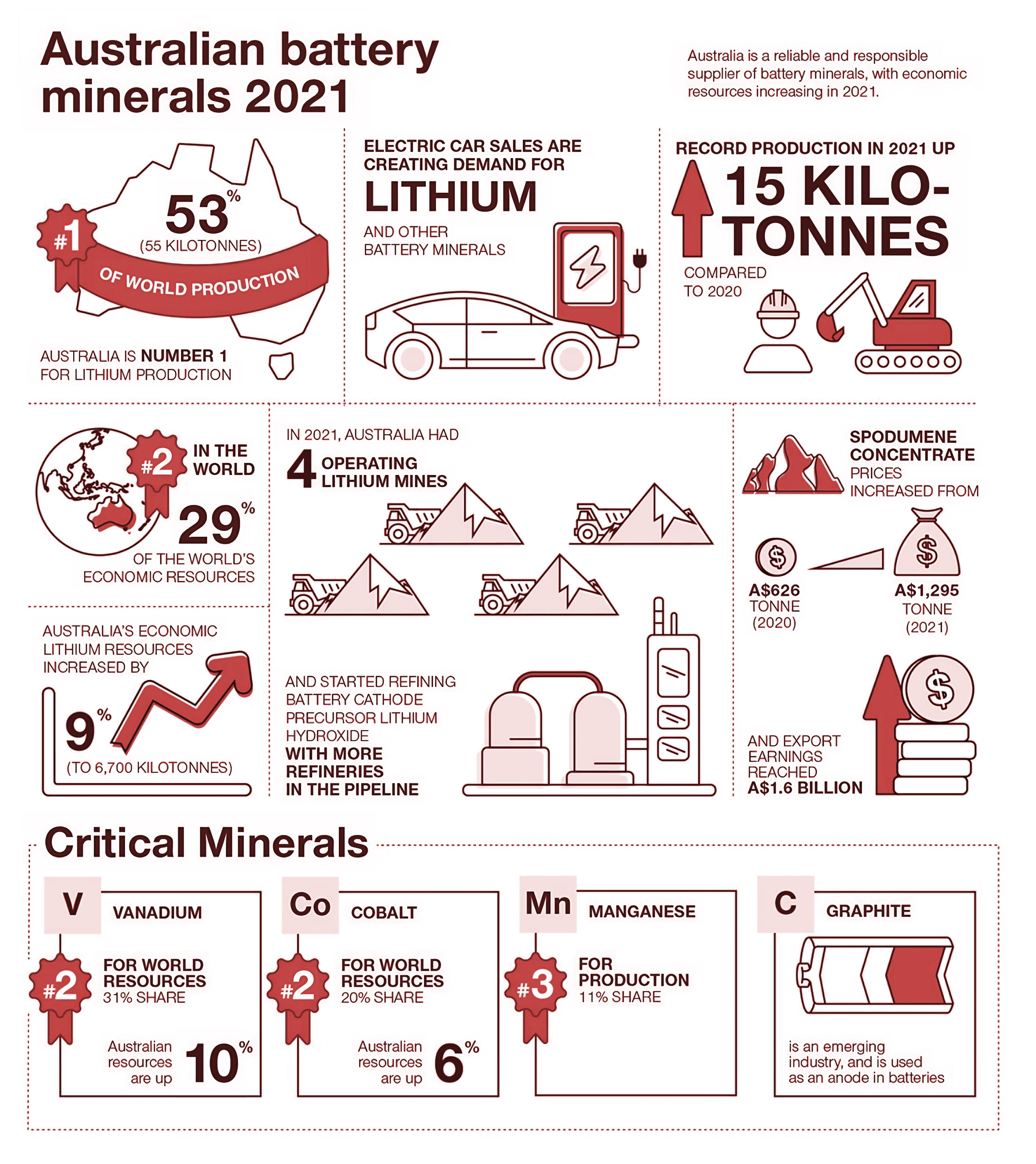

Critical minerals are metallic or non-metallic elements that are essential for modern technologies and low-emission applications, but their supply chains are at risk of disruption, which could have severe consequences for various industries. To mitigate these risks, it is crucial to understand the characteristics of critical minerals, the industries that rely on them, and the associated risks.

Redox’s role in the critical mineral supply chain

Redox offers a diverse collection of chemicals and reagents utilized in the mining, processing, and refining of various minerals such as Lithium, Vanadium, and Rare Earth elements. We have partnered with renowned suppliers such as Kraton, whose Tall Oil Fatty Acid ‘Sylfat’ is considered the leading product in mineral separation. Our mining clients enjoy our broad range of products, along with our top-tier warehouse and distribution network, extensive market expertise, and unparalleled customer service.

What is a critical mineral?

Critical minerals are an essential component of our modern technologies, economies, and national security. They are used to manufacture a wide range of advanced technologies, including low-emission applications like electric vehicles, wind turbines, and solar panels, as well as everyday items like stainless steel and electronics.

Although there is a risk that critical mineral supply chains could be disrupted, it is important to remain positive and proactive in addressing potential challenges. By diversifying supply chains, investing in market development, and promoting sustainable mining practices, Australia can mitigate risks and ensure a stable supply of critical minerals for years.

An Overview of these Minerals

Each country develops its list of critical minerals based on the importance of specific minerals to their industries and evaluating supply risks. However, assessments of mineral criticality are influenced by market and political conditions at a particular time and are subject to change.

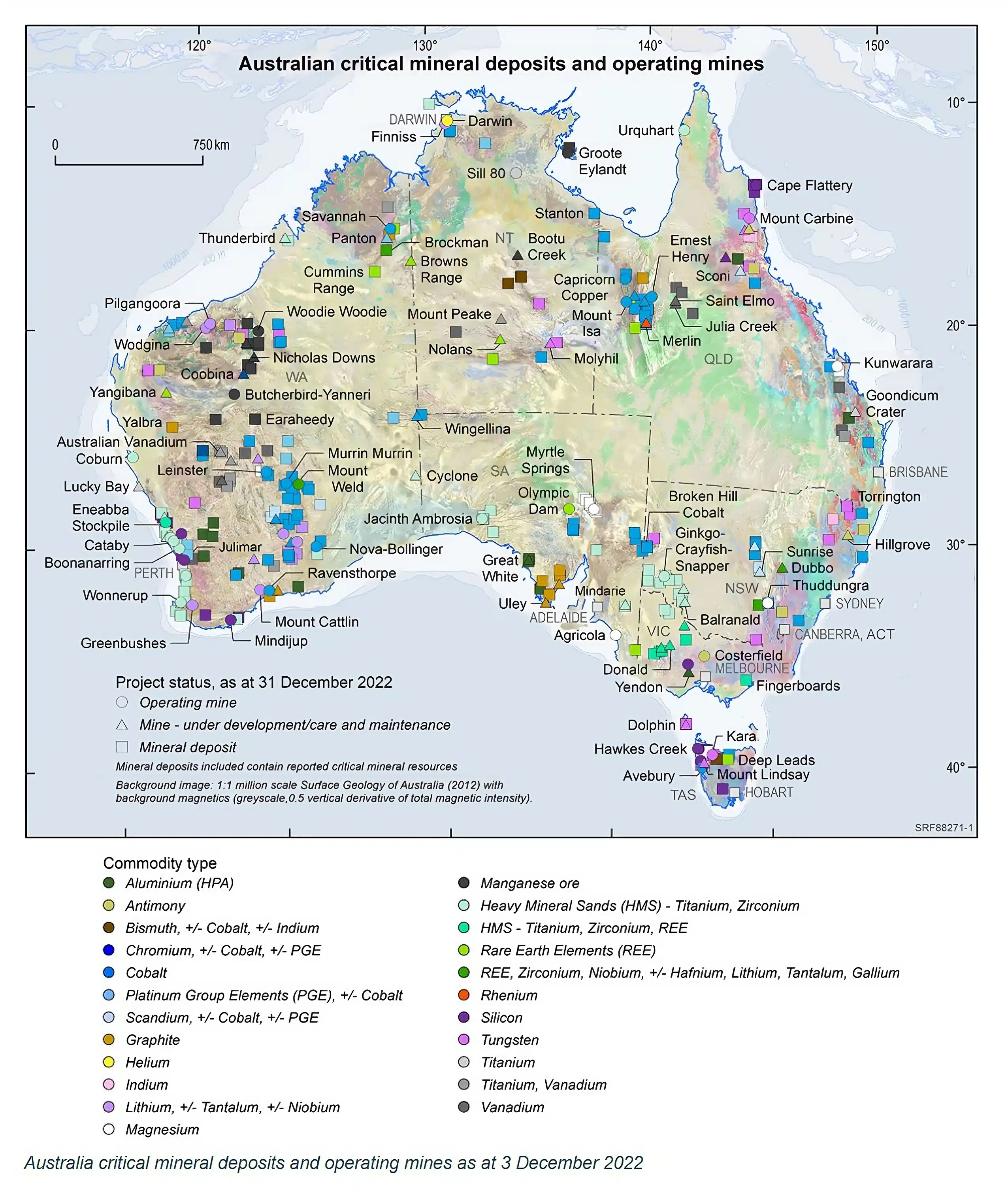

The Australian Government has identified 26 critical minerals by evaluating Australia’s geological potential and global technology needs, especially those of partner countries. The list of Australia’s vital minerals can be found in the 2022 Critical Mineral Strategy.

Australia’s critical minerals sector is expanding to meet the increasing global demand for these strategic minerals. Australia is a top producer of several critical minerals, including lithium, rare earth, and zircon. The country is also discovering and developing more deposits of these minerals, as shown in the Australian Critical Minerals Map.

Australia’s resources industry has expanded exploration and resource definition in response to the rising demand for critical minerals. Economic inventories of several critical minerals increased in Australia in 2021, including platinum group elements, scandium, vanadium, antimony, cobalt, and tantalum.

To conclude, critical minerals play a vital role in our daily lives, and their importance will only continue to grow as we transition towards a low-carbon economy. To ensure a stable supply of these minerals, it is crucial to diversify supply chains, invest in market development, and promote sustainable mining practices.

As a global leader in critical minerals production, Australia has identified 26 critical minerals and is expanding its exploration and resource definition to meet the increasing global demand. By prioritizing the sustainable and responsible production of critical minerals, Australia can ensure their availability for future generations.

Exogenous protease supplementation in broiler chicken diets has primarily been attributed to improvements in protein and amino acids digestibility. Therefore, nutritionists can formulate diets with lower levels of dietary protein while maintaining growth performance.

In a typical wheat-soybean meal-based diet, a reduction of 1% in amino acids reduces feed cost by about 3 AUD/Mt.

The use of exogenous phytase in poultry feed is accepted globally, whilst non-starch polysaccharide enzymes (NSPases) such as xylanase and β-glucanase are commonly used in wheat- and barley-based diets, respectively. However, a combination of 3 or more exogenous feed enzymes is less common. A plethora of publications on protease are available, but reports on the effect of protease in diets that include both phytase and NSPases are less frequent. Recently, a deep litter study was conducted by the University of Sydney on wheat/soybean meal-based diets, including phytase, xylanase and protease at stocking densities similar to commercial practice within Australia.

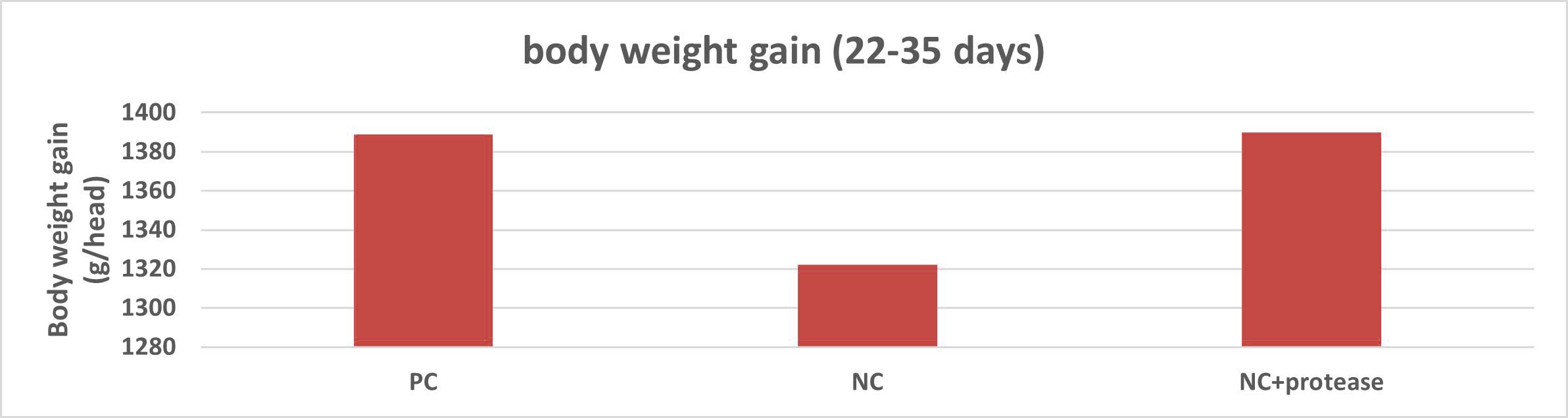

Standard, positive control (PC) diets were formulated to meet or exceed the 2019 Aviagen Ross 308 nutrition specifications and negative control (NC) diets were formulated with a 5% reduction in both crude protein and digestible essential amino acids. A third treatment group consisted of the NC supplemented with the exogenous protease. All diets contained 1000 FTU phytase and 4000 U of xylanase.

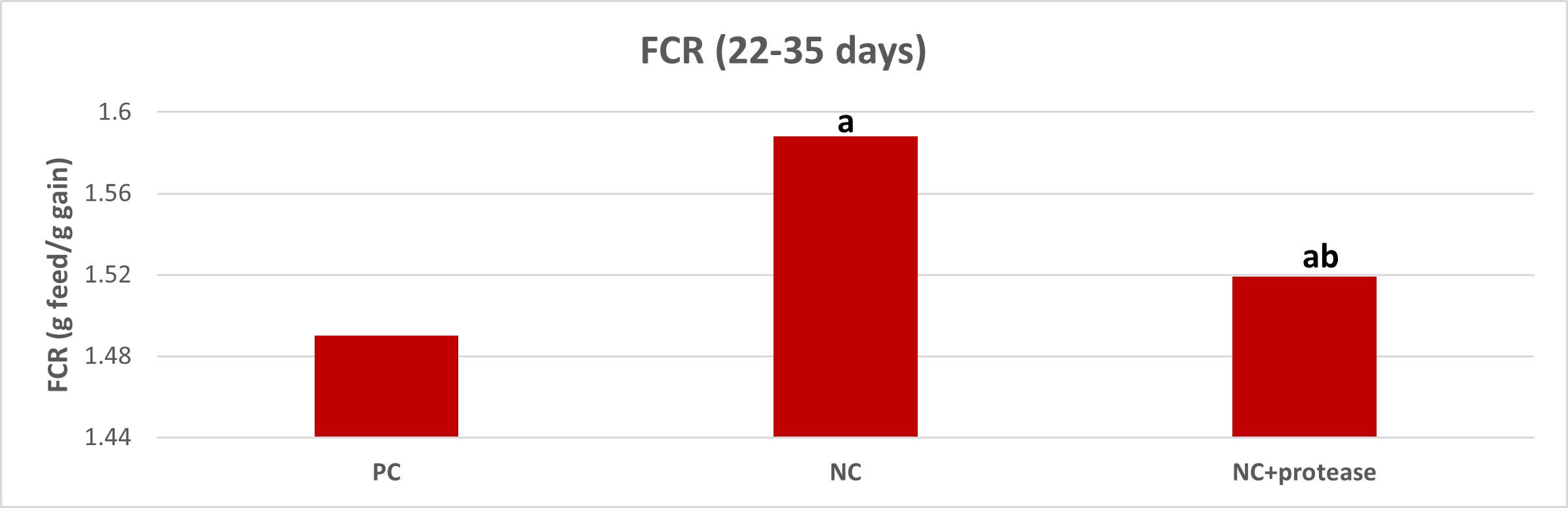

Overall broiler growth to 35 days post-hatch exceeded the Ross 2019 male performance objectives by 10.6% for weight gain (2580 versus 2333 g) and was superior by 5.66% in FCR (1.401 versus 1.485). There was a decline in bodyweight gain and inferior FCR when dietary protein was reduced by 5% (2644 versus 2513 g; P = 0.018 and 1.363 versus 1.432; P = 0.005, respectively). However, the addition of protease ameliorated the loss in performance (2583 g bodyweight gain and 1.408 FCR), and results in the finisher period are illustrated in Fig 1. and Fig 2. It is clearly shown that on the basis of phytase and xylanase, adding protease was able to improve amino acids digestibility further and recover 5% reductions in broiler finisher diet essential amino acids and crude protein without an adverse effect on broiler performance.

Fig 1. Bodyweight gain in male Ross 308 broilers from 22-35 days post-hatch (P = 0.061).

Fig 2. Feed conversion ratio in male Ross 308 broilers from 22-35 days post-hatch (P = 0.008).

Our Partnering Manufacturers