You might not notice it when you look around, but titanium dioxide (TiO2) is everywhere. From the paint on your walls to the sunscreen you apply before heading out, TiO2 is an essential mineral that plays a significant role in various industries.

What is Titanium Dioxide?

First isolated and named by William Gregor in 1791, titanium dioxide is a naturally occurring, chemically stable, non-toxic, and odourless mineral. Its outstanding light-scattering properties make it valuable in multiple applications, such as cosmetics, sunscreens, paints, coatings, plastics, and even food products.

But that’s not all. TiO2 is also a photocatalyst in environmental applications, such as air and water purification, and is a critical component in electronics and solar cells. Its versatility and diversity make it one of the world’s most widely produced and consumed materials.

How is Titanium Dioxide Used?

TiO2 is a versatile mineral that is widely employed across a multitude of industries. It serves as a light-scattering agent in surface coatings and road markings, contributing to a brilliant and reflective finish. In the world of plastics, paper, inks, and rubber, TiO2 functions as a whitening agent, providing increased opacity and visual appeal to these materials.

Moreover, TiO2 is an indispensable ingredient in the production of cosmetic products and sunscreens, owing to its remarkable capacity to protect against harmful ultraviolet (UV) radiation. Additionally, in the food industry, it is used to brighten and whiten various products.

Despite its multifaceted applications, the most significant demand for TiO2 comes from the surface coatings and plastics industries, which account for nearly 80% of its global consumption.

Titanium Dioxide functions as a light-scattering catalyst in surface coatings and road markings, enhancing the creation of a dazzling and reflective surface.

What Influences the Pricing of Titanium Dioxide?

The price of titanium dioxide is subject to various factors, including shipping costs, raw materials such as ilmenite, and the production process. Depending on production location, i.e., China is the world’s second largest TiO2 producer and has a higher percentage of manufacturing via the sulphate process compared to the USA, where chloride TiO2 production is more dominant. There are two primary methods for producing titanium dioxide: sulphate and chloride. Sulphate production is more prevalent, while chloride production is generally considered higher quality, albeit at a higher cost.

These factors all play a role in determining the final price of titanium dioxide, a vital mineral used in a wide range of applications.

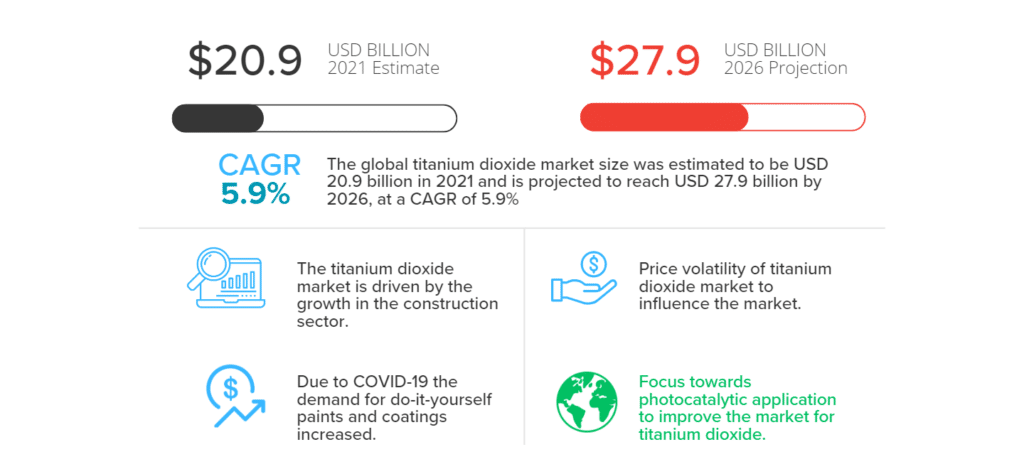

The global titanium dioxide market was valued at USD 20.9 billion in 2021. It is projected to reach USD 27.9 billion by 2026, growing at a cagr 5.9% from 2021 to 2026. It is driven by paints & coatings application in construction, automotive and industries during the forecast period. APAC is dominating the region in paint & coating applications with an increase in demand from China and India.

How Can Redox Help?

We offer Titanium Dioxide in various packaging sizes, ranging from 25kg bags to 500kg and 1000kg bulker bags. The product is available in multiple grades, including Anatase and Rutile, produced through sulphate and chloride production processes. Customers can choose from various options to suit their specific needs.

Trust Redox to deliver the best results for your business. Contact us today to discover how we can be an essential partner in your sourcing strategy.

One of the most powerful solutions to ensure a safe mine environment is fire retardant anti-static (FRAS) materials, which protects against all kinds of hazardous situations like fuel fires or explosions caused by heat build-up, static sparks, and other combustible substances that could seriously compromise your mine’s safety.

Materials such as rubber, polyurethane, PVC, polyethylene, polypropylene and polyester are often used to make base materials that are then manufactured into products for underground coal mining. Fibre-reinforced resin materials such as fibreglass and carbon fibre composite are also used.

The products manufactured include ventilation sheeting (brattice) and ventilation stoppings, ventilation ducting (rigid and flexible), dust curtains, venturi blowers, air fans, pipes, conveyor belting and conveyor accessories.

Recommendations on FRAS materials

Mine operators of underground coal mines must ensure that control measures are implemented for products subject to the accumulation of static charge. The control measures should include the following:

- Procedures to verify the products are installed per the manufacturer’s directions for static discharge.

- Appropriate measures are implemented to ensure that the properties of FRAS materials are maintained over time.

Manufacturers of FRAS-rated materials must ensure that testing is undertaken in accordance with the relevant requirements of MDG 3608 by an independent testing facility for:

- All FRAS material intended for use in an underground coal mine

- Any change of material composition or manufacturing technique for a FRAS-rated material, including changes of colour, to verify the suitability of the material.

Manufacturers and suppliers of products incorporating FRAS materials as components must ensure that:

- The product’s design incorporates suitable controls to prevent the accumulation of a static charge on the FRAS components.

- Instructions for the safe use of the product include mounting or suspension requirements to prevent the accumulation of a static charge on the FRAS components.

- Any change of material composition or change to the product design, including changes of colour, size or placement of eyelets, rivets or mountings, are tested in accordance with the relevant requirements of MDG 3608

- The product is suitably marked to indicate compliance with MDG 3608.

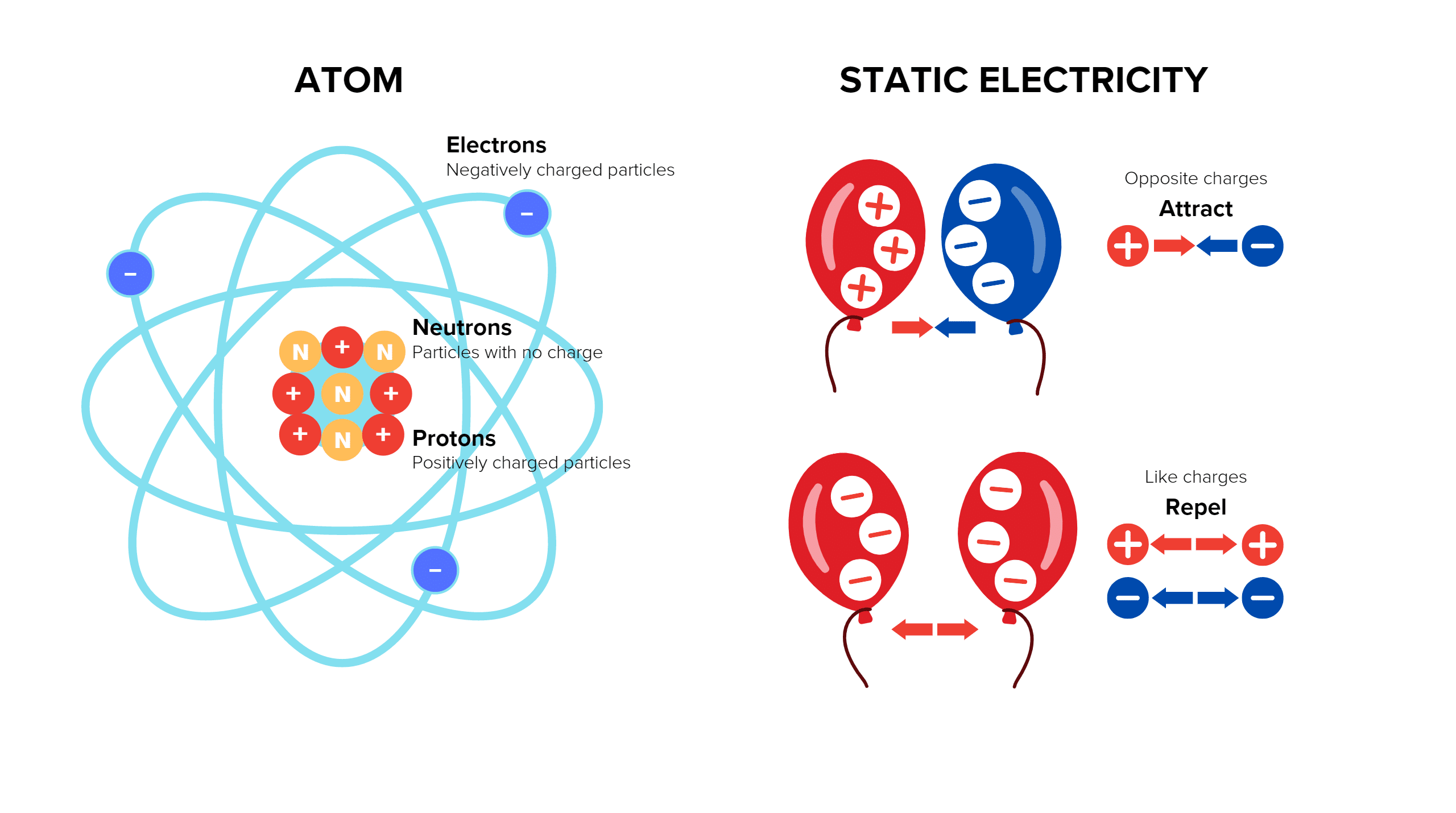

Every object is made of atoms that are typically electrically neutral. They contain an equal number of protons (positive charge) within their nucleus and electrons (negative charge) surrounding the nucleus. Static electricity occurs when there is a separation of positive and negative charges within or on the surface of a material or between materials. Electrons may move from one object to another, leaving one object with a negative charge and the other with a positive. When the objects are separated they retain the charge imbalance.

How can we help?

To minimise risks, improve occupational health and safety hazards, and, importantly, minimise underground ignitions, fire retardant anti-static (FRAS) materials are now required in all NSW underground mines, monitored by the NSW resources regulator.

Redox offers many polymer/composite options for differing FRAS application solutions.

Contact our Plastics division today if you would like to learn more about material solutions supported by our many international principal partners.

EVA Resin is an elastomeric polymer that produces rubber-like materials known for their soft and flexible properties.

It is predominantly used in numerous crucial industrial areas such as:

- shoe soles,

- sheets,

- wire and cable,

- hot melt adhesive, and

- solar cell encapsulation

But the use cases don’t end there, EVA foam is extremely versatile but is taken for granted by most even though it’s found in automotive, building, marine, electronics, healthcare, product packaging, sports, leisure, and recreation products. No doubt, you own something or have used something that contains this flexible material.

For example:

- EVA is competitively used in rubber and vinyl products in many electrical applications.

- It’s used to give plastic wrap its “clinginess.”

- EVA emulsions are developed into adhesives used in packaging, bookbinding, bonding plastic films, metal surfaces, and coated papers.

- It’s also used with wax and resin additives to make hot-melt adhesives, hot glue sticks, and top-notch soccer cleats.

- It is even used to make children’s foam stickers.

EVA foam is extremely adaptable, most people take it for granted despite the fact that it’s used in a variety of items.

EVA foam is highly adaptable, and most people take it for granted despite the fact that it’s used in a variety of items.

EVA has excellent clarity and gloss and possesses low-temperature toughness; it’s vUV resistant, contains waterproof adhesive properties, is chemical-resistant, and has excellent processability.

As you can see, it’s an excellent and adaptable material.

Working with a supplier that can guarantee consistent quality is critical; Redox is in a great position to meet and exceed your expectations. Contact one of our industry specialists today.

Our Partnering Manufacturers