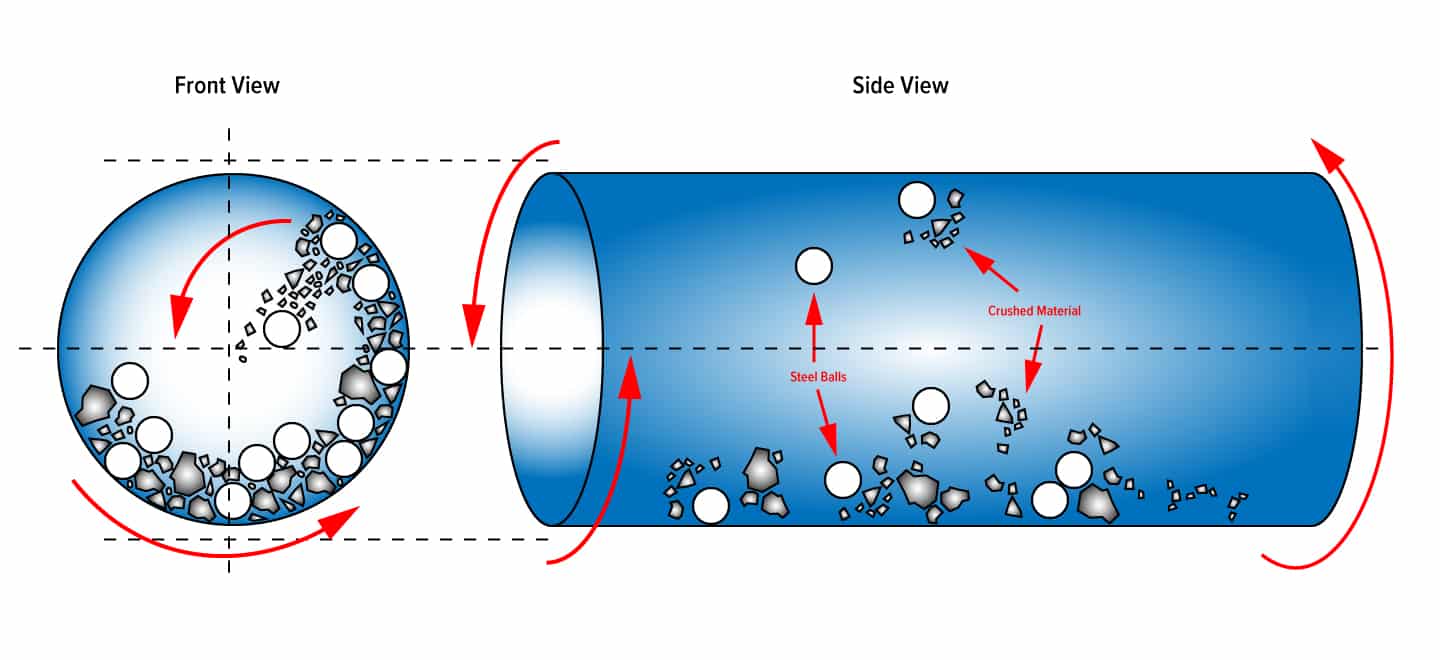

The general idea behind the ball mill and grinding media is an ancient one, but it was not until the industrial revolution and the invention of steam power that an effective ball milling machine could be built.

Grinding Media is primarily used in ball milling (ore processing) and regrind (cement or similar) applications. The critical factor to quality and reliability is the hardness or “wear rate” of the ball media being used. Where there are other forms like rods and cyplebs, the ball is the most common.

The three major types of ball media are:

- Forged Steel

- Chrome

- Ceramic

For the ore processing application, most mines will have at least 2 ball mills; a primary and a secondary and occasionally some will utilise a regrind mill.

In the primary and secondary, either forged steel or chrome is used; rarely do they use a combo of both.

In the regrind mill; generally ceramic media is used.

Sizes vary depending on the intended application:

- Forged steel and chrome media come in sizes from 25mm to 140mm most commonly.

- Ceramic will come in 1-22mm; most commonly 1-5mm.

Chrome is broken into “low content chrome” and “high content chrome”. Low content chrome historically has smaller ball size and can replace the need for regrind mill altogether.

Want to know more? Contact one of our industry specialists today and ask them today.