Ion Exchange is a reversible chemical reaction where dissolved ions are removed and replaced with other ions of the same/similar electrical charge. This mechanism is exploited by Ion Exchange Resins which are a medium that facilitates the exchange of ions between the resin beads and the water as it moves past inside a vessel.

This process can create ultra-pure water for use in the production of semiconductors, solar photovoltaics, pharmaceuticals, and flat panel displays for rinsing/cleaning and various other critical processes.

Food manufacturers can use Ion Exchange Resins in a host of ways, from purifying water to use as an ingredient to decolourising, demineralising, and removing taste and odours.

In power stations Ion Exchange Resins are used to demineralise feed water and treat condensate from the steam cycle. They are even utilised to recover various metals such as gold, uranium, and copper.

Possibly the widest use is as a pre-treatment step in various water treatment settings where they can work to improve the efficiency of Reverse Osmosis plants by lessening the load on filter membranes.

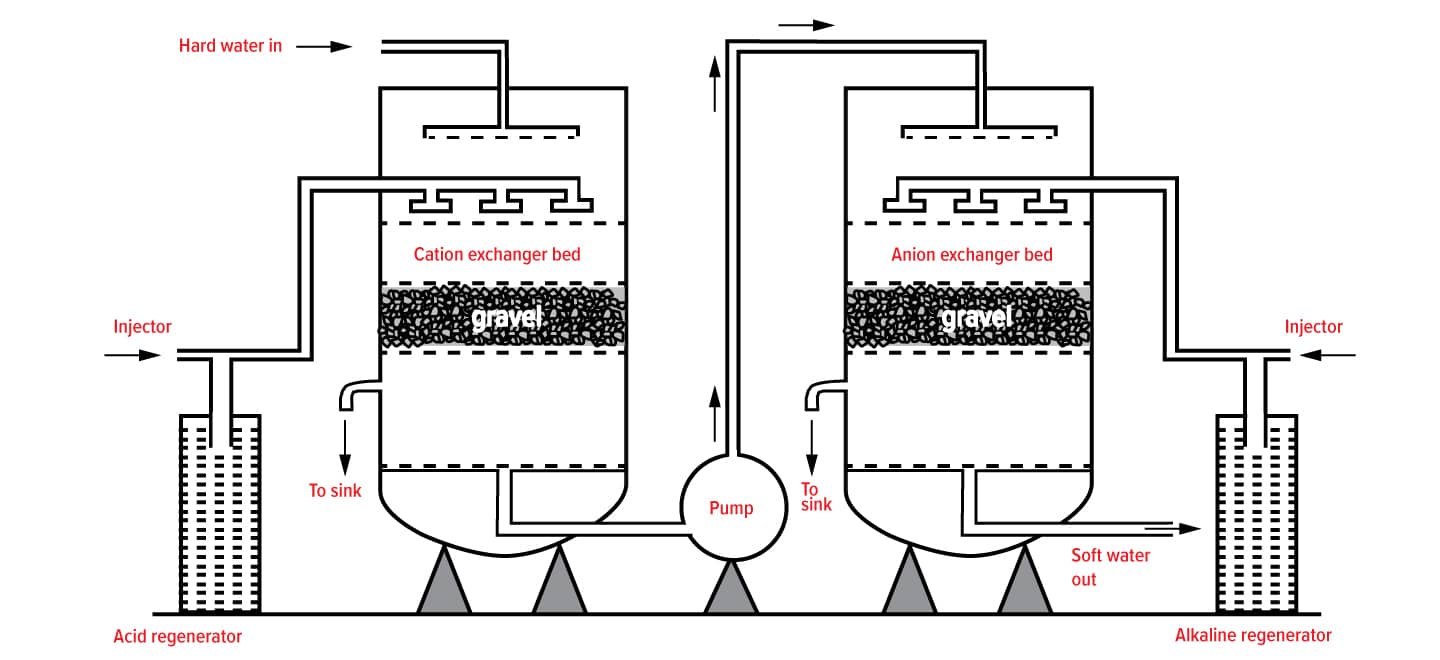

The two most commonly used Ion Exchange Resins are:

- Cation resins, that exchange positively charged ions, such as sodium, for calcium,

- Anion resins, which exchange negatively charged ions, such as chloride, for arsenic.

They are used to remove poisonous and hazardous metal ions from solution, replacing them with more innocuous ions, such as sodium and potassium.

How Ion Exchange Resins work

Water softening is the removal of calcium, magnesium, and certain other metal cations in hard water. The resulting soft water requires less soap for the same cleaning effort, as soap is not wasted bonding with calcium ions.

Soft water also extends the lifetime of plumbing by reducing or eliminating scale build-up in pipes and fittings.

Hard water is formed when water percolates through deposits of limestone, chalk or gypsum which are largely made up of calcium and magnesium carbonates, bicarbonates and sulphates. Iron oxides or iron carbonates can give a reddish-brown colouration to hard water deposits.

And while The World Health Organization says that “there does not appear to be any convincing evidence that water hardness causes adverse health effects in humans”, there are studies that correlate domestic hard water usage with increased eczema in children.

They can help improve both access and quality by helping provide a higher level of filtration for drinking water in developing countries around the world.

Redox can supply it in 25L and 1000L bags.

Contact us today and speak to one of our industry specialists to find out more.

In this month’s Employee Spotlight, we talk to Director and Food Industry Group Manager, Ken Perrins.

How has your career progressed over the years, what was your first important role?

My journey at Redox started a little different to most. I’m fortunate enough to work with a number of other successful family companies, especially in the wine industry. Those family businesses have beautiful romantic stories of the younger generation running around a vineyard or wine barrels. However, for my cousins and I, we grow up with forklifts, warehouses and barrels of caustic soda. Still a lot of fun!

From an early age we were mystified by the chemicals that our Grandfather would bring home from work. He made crystals with copper sulphate and change the colour of copper coins to silver with Sodium Zincate. That curiosity in chemistry developed from a young age and continues to motivate and interest me today.

I started off filing shipping documents during school holidays. Today I have a few responsibilities, one of which is Food Industry Manager, which I have seen grow immensely in the past 25 years. We can now boast that we supply pretty much all of the major food & beverage manufacturers in Australia and New Zealand and are also making great progress in Malaysia and USA.

How has Redox’s food industry presence developed over the years, what are the opportunities you see in the area?

Without question the food industry is evolving rapidly with consumer trends. Consumers are very aware of the foods they eat. Both from a health perspective and an ethical/responsible sourcing perspective.

Reading food labels at a grocery store. Modern customers have a better understanding about the nutritional value they are seeking when selecting products.

With this in mind, Redox has evolved with the changing market and now offer a very different product portfolio than that which was offered when I started 25 years ago.

We see huge potential in this space and continue to look for novel and innovative ingredients to offer our clients.

What are your work mates like?

I can sincerely say that I work with a great bunch of people, in and outside of the food industry. It has been a pleasure to know many of our staff for 20+ years.

Around the water cooler there is always great banter about weekend activities, family, sports as well as the odd bit of business.

I hear you are an avid Scuba diver, what got you interested in that?

Before children I had the time to Scuba dive, but don’t get to much anymore. Now and again, I spearfish, but must say I’m not very good at it. Recently I’ve been on a mission to get my kids off the ‘screens’ and have taken them on a few overnight hikes in the national park.

Bit of a cliché but a really great bonding experience.

Glycerine, Its name comes from the Greek word Glykys, meaning sweet, but this once considered insignificant product sprung from less humble beginnings.

Glycerine is a trihydric Sugar Alcohol (polyol) that presents as a colourless, odourless, viscous and slightly sweet liquid. It is commonly used as –

• A sweetener, to make medicine more palatable

• A Humectant, to keep foods moist

• A moisturiser, to keep skin supple

• A solvent, to carry flavours/colours and to dissolve grime

• A plasticiser, to improve texture in, icing/frosting and confectionary

• A lubricant, to maintain the machinery that manufactures surface coatings, resins, paper, rubber, plastics and urethane polymers.

Let’s dig a little deeper shall we.

In the beginning…

Glycerine was first synthesised in the late 1700’s by soap manufacturers but at the time, it was considered an economically insignificant product. In 1846 Nitro-glycerine is developed by Ascanio Sobrero by treating glycerol with a mixture of nitric and sulphuric acid. Then in 1866, a Swedish chemist named Alfred Nobel developed Dynamite, an improvement of nitro-glycerine.

Feats of engineering such as the Panama Canal and Central Pacific Railroad would not have been possible without dynamite. Suddenly, Glycerine was no longer considered an economically insignificant product.

From economically insignificant to a necessity.

Glycerine is now produced on a much larger commercial scale by hydrolysis or transesterification of vegetable oil, which produces fatty acids, soap noodles, or Biodiesel whilst generating crude glycerine as the by-product.

Crude glycerine is further refined by vacuum distillation and bleaching with activated carbon to produce a 99.7% pure pharmaceutical grade material that is safe for human consumption, and is a necessary component in a variety of household products, most notably food, cleaning agents and toiletries.

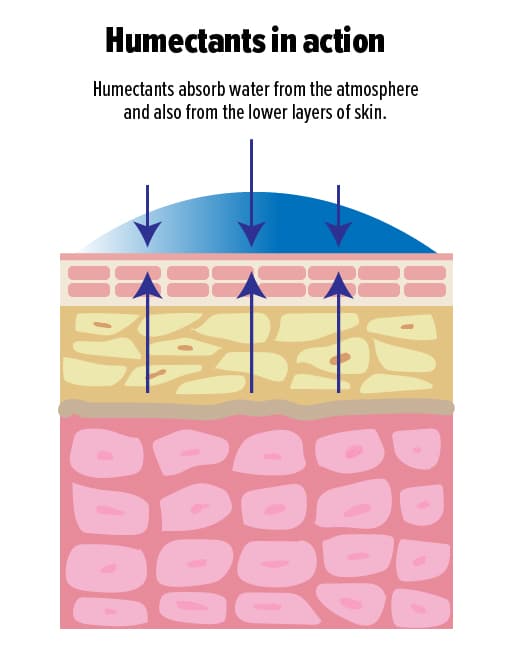

And because Glycerine is a humectant, it is commonly used in skin care products with other types of moisturizing agents, to trap the moisture that it then draws into the skin.

According to a 2016 study, Glycerine is “the most effective humectant” in comparison with numerous others.

Where can I get it?

Redox supplies thousands of tonnes of Glycerine annually to customers based in New Zealand, Australia, Malaysia and USA, including to some well-known multinational brands whose everyday products are likely sitting at home in your Kitchen, Bathroom, or Laundry.

Want to know more? Contact one of our industry specialists today and ask them about Glycerine.

Our Partnering Manufacturers