Redox are proud distributors of a range of products from United Initiators including CAROAT®.

CAROAT® is the preferred option to solve problems which are caused by super chlorination when using common pool & spa sanitizers, such as chlorine, bromine and other non-halogenated alternatives.

CAROAT® is characterized by the following:

- odourless

- fast dissolving

- a powerful oxidizer (high oxidation potential)

- oxygen-based, doesn’t contain chlorine

- unaffected by UV degradation

- compatible with sanitizers based on chlorine, bromine and other non-halogen based alternatives

CAROAT® is a non-chlorine oxidizer used for shock treatment applications. It has all the positive functionality of a chlorine oxidizer while avoiding the negative side effects.

CAROAT® is the preferred option to solve problems which are caused by super chlorination when using common pool & spa sanitizers

Download the United Initiators Pool & Spa technical bulletin here and if you have any questions you may refer them to our dedicated Watercare Technical Manager.

This versatile material can also be used in a range of other applications such as –

Denture cleaners: Effective main ingredient in cleaning tablets for dentures.

- Bleaching agent: CAROAT® has a bleaching effect comparable to that of organic peracids; in the TAED/perborate system it is particularly effective at low temperatures.

- Biocidal effect: Suitable as an additive to acidic cleaning agents with bleaching and disinfectant effect.

- Effluent treatment: Oxidative treatment of problematic effluents; sulfide oxidation, nitrite oxidation and cyanide detoxification.

- Plaster additive: Addition of CAROAT® leads to generation of oxygen and improved product characteristics (e.g. thermal insulation, water absorbency, mechanical properties).

- Metal treatment: Microetchant: Use for etching printed circuit boards.

- Textile finishing (shrink proofing of wool)

- Chemical synthesis (production of dioxirane)

- Paper manufacture (repulping, particularly of wet-strength paper).

About United Initiators

United Initiators is a global and leading producer of peroxide-based initiators, Hydrogen Peroxide and specialty chemicals. The company offers a broad range of organic peroxides, persulfates, Hydrogen Peroxide and selected specialty chemicals. Organic peroxides are used in a large variety of polymerization processes and polymer processing applications.

The use of persulfates ranges from aqueous polymerization processes, over electronics, disinfection, cosmetics, metal etching, paper treatment, Oil & Gas exploration to a broad field of bleaching processes. Hydrogen Peroxide is used in consumer goods, disinfection applications and is an enable for the world’s digital economy.

United initiators has several production facilities in Europe, North America, Asia-Pacific, Turkey and India. UI’s mission is to be the best serving peroxide producer for a growing world.

How Can Redox Help?

With Redox, rest assured that our unwavering commitment to excellence will empower your business.

Contact us today to discover how we can be an essential partner in your sourcing strategy, or click here to view the product page.

Milk fever is a hypocalcaemic paresis at parturition, caused by the sudden and large demand of calcium from blood due to the onset of lactation in dairy cows. It is now clear that this large demand of calcium can not be met by dietary calcium supplementation but regulated by bone calcium homoeostasis mechanism.

A nutrient balanced diet specially formulated for prepartum cows can effectively prevent hypocalcemia and increase Ca availability during the periparturient by maintaining Ca homeostasis. Currently, there are two dietary approaches to prevent milk fever.

- Create a negative dietary cation-anion difference (DCAD)

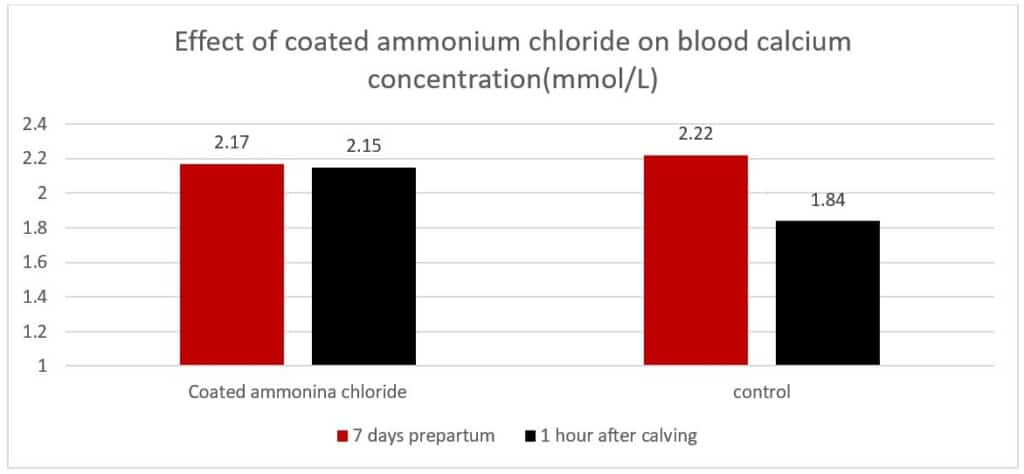

It is demonstrated that by adding anions, reducing prepartum DCAD from +200 to -100 (-50 to -150) mEq/kg increased blood Ca on the day of parturition, increased postpartum dry matter intake (Figure 1). The coated ammonium chloride is an anionic salt with good palatability, providing -13,088 mEq/kg DCAD value.

Figure 1. Effect of coated ammonium chloride on blood calcium concentration

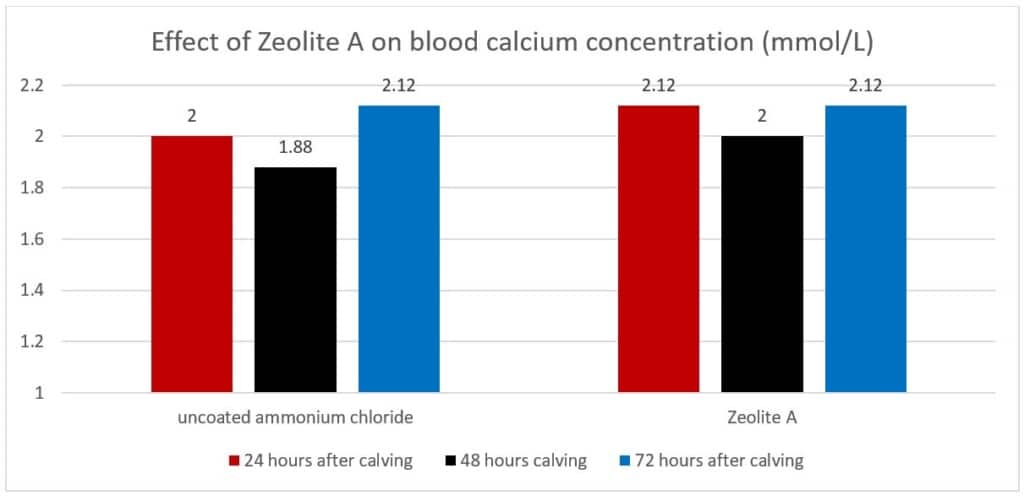

- Add synthetic zeolite A to bind up Ca in the gut.

Zeolite addition does not acidify the diet but bind Ca in the gut to mobilize Ca from bone. Compared with normal (uncoated ammonium chloride), Zeolite A addition showed the higher blood Calcium concentration at 48 hours after calving (Figure 2).

Figure 2. Effect of Zeolite A on blood calcium concentration (mmol/L)

A study compiled by our Redox Animal Nutritionists.

In recent years, it is widely accepted that based on an ideal amino acid profile, a moderate reduction of dietary crude protein (CP), 20 to 30 g/kg, will not compromise broiler chicken performance.

These reduced CP levels are usually achieved by increasing feed grains such as wheat inclusion at the expense of soybean meal, relatively more starch replacing fat as the non-protein energy source. It is reported that increased non-starch polysaccharides (NSP) presented in wheat will enhance faecal bile acids loss, resulting in either increased bile acids pool or bile acids deficiency.

Traditionally bile acids are considered to be bio-surfactants, assisting intestinal digestion and absorption of lipids and fatty soluble vitamins such as Vitamin A, D, E and K, and thereby improving nutrient utilization. Recently it has been shown that bile acids act as regulators of gut microbiome and play a key role as signalling molecules by modulating cell proliferation, gene expression, lipid and glucose metabolism. To evaluate if the reduced CP diet could affect fat digestibility, the University of Sydney conducted a broiler chicken trial by adding the exogenous bile acids to both normal CP and reduced CP diets.

Standard, normal protein (SC) diets were formulated to meet or exceed the 2019 Aviagen Ross 308 nutrition specifications and reduced protein (RC) diets were formulated with a 3 g/kg CP reduction in the starter (0-14 d), grower (15-28) and finisher (29-42) phases. Another two treatments consisted of the SC and RC supplemented with the exogenous bile acids 200 mg/kg, respectively. All diets contained 1000 FTU phytase and 4000 U Xylanase.

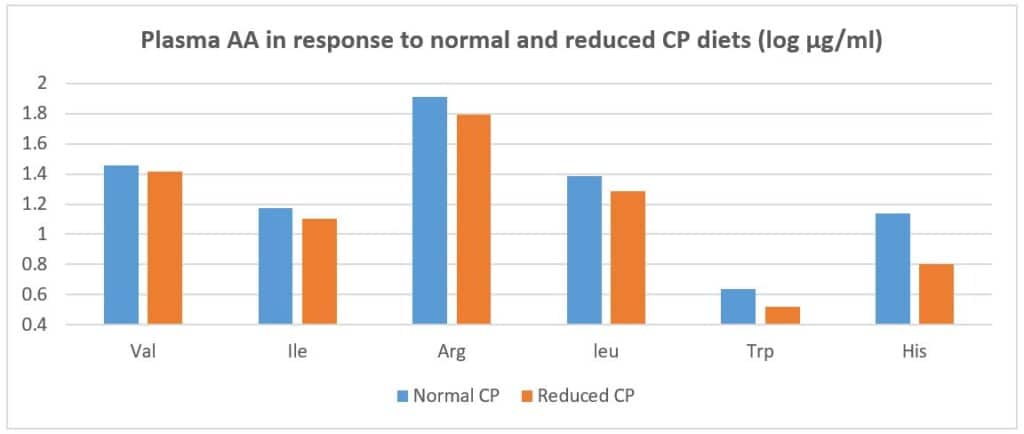

Surprisingly, reducing 30 g/kg CP significantly depressed body weight gain and feed intake by 4.8 % and 2.8%, respectively (P < 0.01) although chicken performance fed on RP diets exceeded the Ross 2022 male performance objectives by 4.31% for weight gain (3361versus 3222 g) and was superior by 2.76% in FCR (1.475 versus 1.517). Figure 1 clearly showed that the current ideal amino acids profile resulted in significant lower plasma Valine, Isoleucine, Arginine, Leucine, tryptophan and histidine concentrations in RP diets, indicating that the current ideal amino acids profile could not support 30 g/kg CP reduction although it might achieve commercially satisfied performance.

Figure 1. Plasma AA concentrations in response to normal and reduced CP diets (log µg/ml)

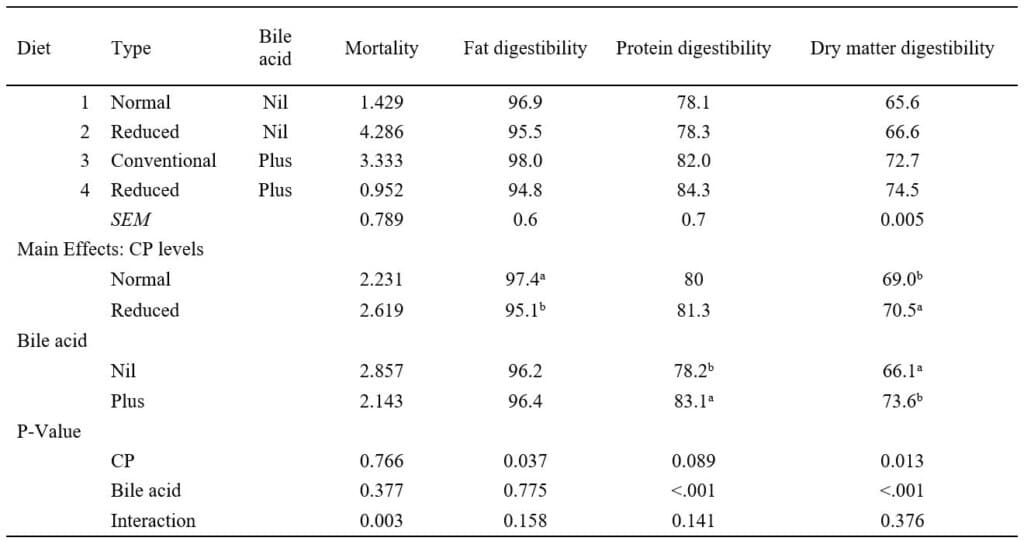

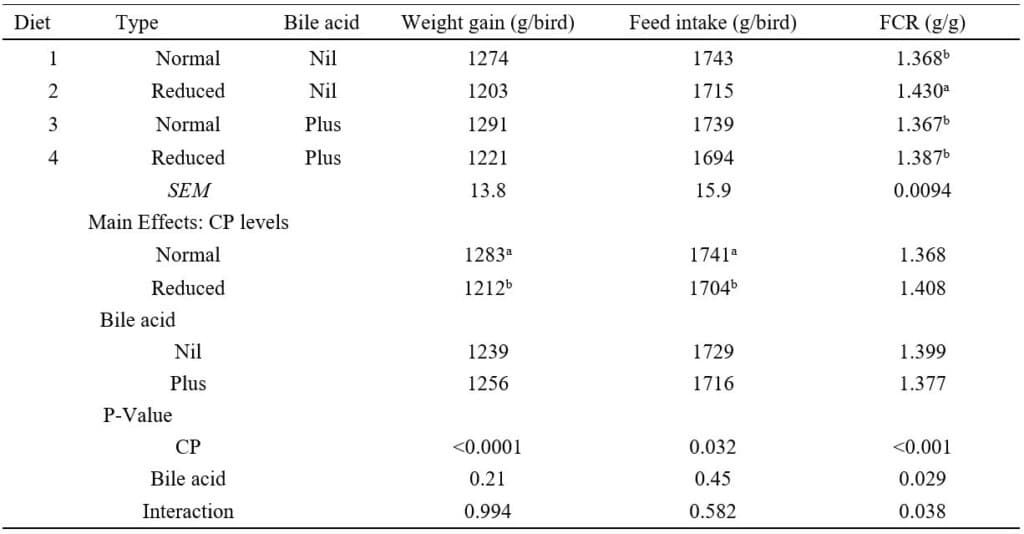

Interestingly, the addition of the exogenous bile acids had no effect on crude fat digestibility but significantly improved crude protein and dry matter digestibility (Table 1) possibly due to reduced endogenous bile taurine loss. In Table 1, it is also shown that adding bile acids to the RP diet, significantly reduced mortality rate (P < 0.003).

Table 1. The effect of dietary treatments on the mortality and digestibility of fat, CP and dry matter (%)

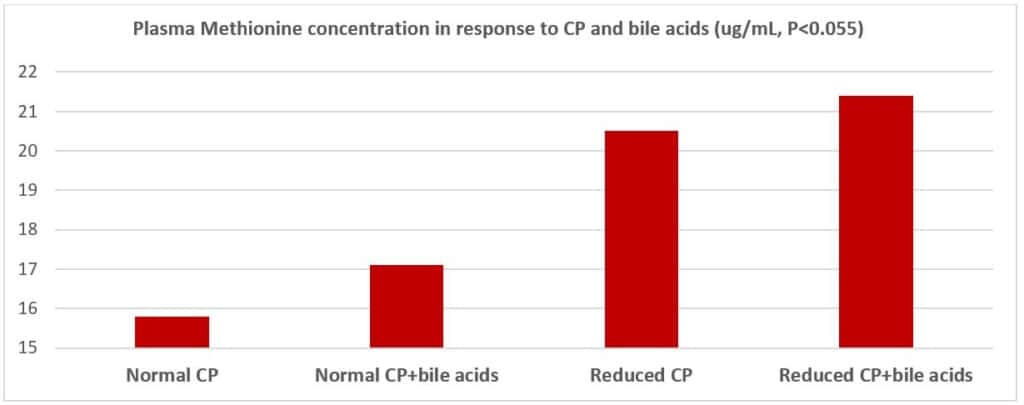

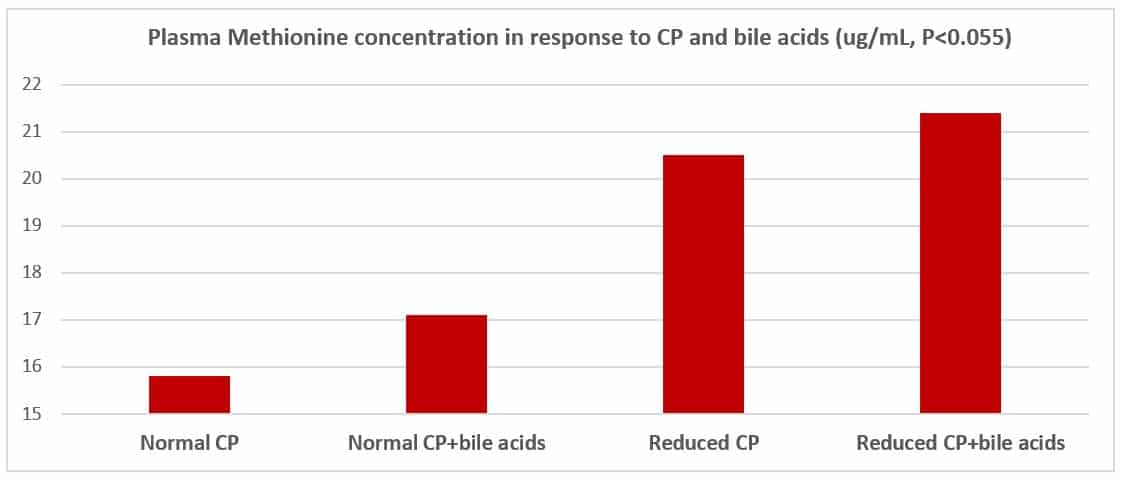

In RP diets, due to other amino acids such as valine, isoleucine and arginine limitation, dietary methionine becomes more surplus but adding bile acids significantly increased plasma methionine concentration (Figure 2). Therefore, the efficacy of bile acids may be related to dietary methionine concentration which could convert to taurine. In general, in grower period (15-28), adding the exogenous bile acids to a RP diet achieved the best chicken performance and FCR was improved by 5 points (Table 2).

Figure 2. Plasma Methionine concentration in response to dietary protein and bile acids addition (µg/mL)

Table 2. The effect of dietary protein levels and bile acids on growth performance (15-28 days)

A study compiled by our Redox Animal Nutritionists.

In recent years, the poultry and pig industry has been successfully developing reduced crude protein (CP) diets to reduce Nitrogen pollution and improve the litter quality. It is reported that 2.5%-unit crude protein reduction in poultry or pig diets will reduce ammonia by 25%. Considering 1 MT ammonia is equivalent to 2.11 MT carbon dioxide, this trend will have a tremendous impact on climate change. However, nutritionists need to do more to deal with reduced protein diets.

1. Reduced protein diets and limiting amino acids (AA)

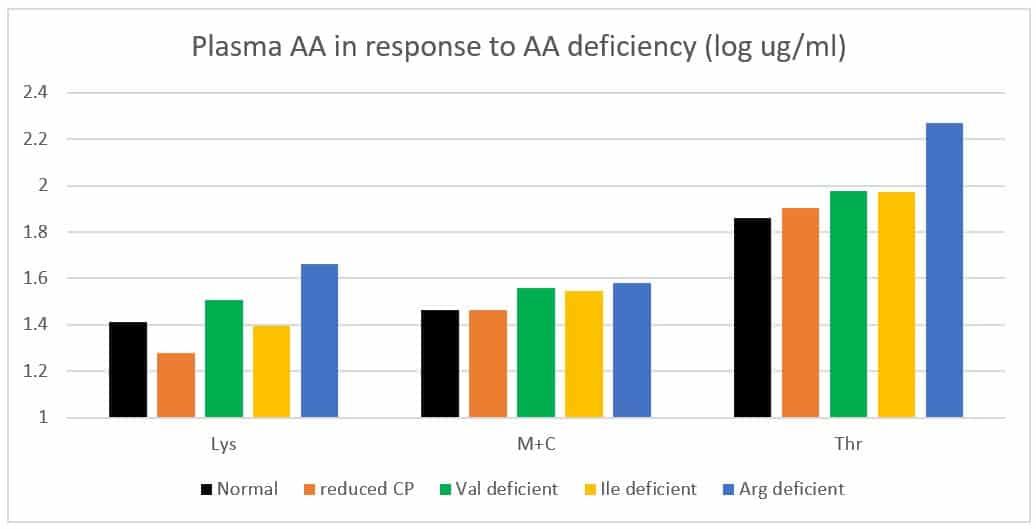

Traditionally, in wheat-soybean meal-based poultry diets, unbound crystalline L-methionine, L-Lysine and L-Threonine have been routinely added to meet chicken growth requirements. It is clear now that by further adding L-Valine, L-Isoleucine and L-Arginine, the crude protein level could be reduced by 1.5 to 2% unit but not compromise chicken performance. It is noticed that in reduced protein diets, dietary valine or arginine deficiency will result in plasma Lysine, Methionine and Threonine accumulation; Dietary isoleucine deficiency will result in plasma methionine and threonine surplus, indicating that in reduced protein diets, if L-Valine, L-isoleucine and L-Arginine were not added, dietary lysine, methionine and threonine cannot be fully utilized by chickens to contribute to muscle growth. In particular, dietary Arginine deficiency resulted in a considerable surplus of threonine, affecting mucus secretion. (Figure 1).

Figure 1. Plasma AA concentrations in response to dietary AA deficiency

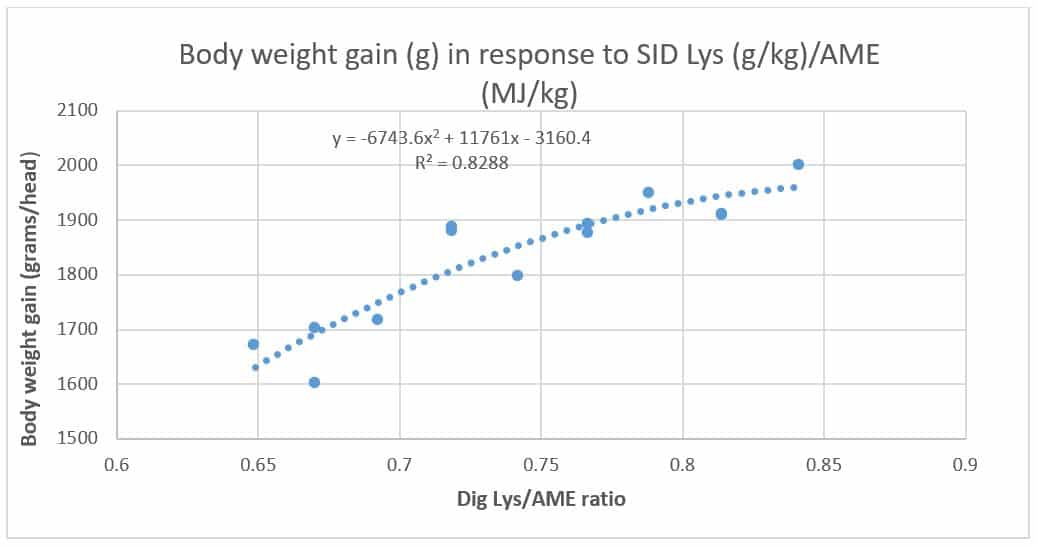

2. Optimal SID Lysine (g/kg) to AME (MJ/kg) ratio in reduced protein diets

While formulating a reduced protein diet, nutritionists will usually use more grains and reduce oil or fat contents. Considering the higher energy efficiency of oil or fat, it is not clear yet if we need to increase apparent metabolizable energy (AME) requirement in reduced protein diets. However, in 2018, the University of New England (UNE) published a broiler chicken trial paper to show that AME requirement might mainly depend on dietary lysine concentration. In grower period, the optimal SID lysine (g/kg) to AME (MJ/kg) was determined to be 0.88 (Figure 2).

Figure 2 Body weight gain in response to SID Lys/AME ratio on 14-35 days

3. Endogenous loss of taurine in reduced protein diets

It is noticed that in reduced protein diets, more starch will replace fat as the dietary non-protein energy source, leading to more faecal bile acids loss. Recently, the research in Massey University demonstrated that the major endogenous amino acid loss in broiler chicken bile would be taurine. Considering taurine is an important anti-oxidant to regulate immune system health, in stress situation, the reduced protein diet might result in disease infection. It is widely known that taurine is produced by cysteine in chicken body and dietary methionine can convert to cysteine. In a recent broiler chicken trial conducted in the University of Sydney, adding exogenous bile acids to the reduced protein diets significantly reduced mortality rate due probably to increased plasma methionine concentration (Figure 3).

Figure 3. Plasma methionine concentration in response to bile acids addition

4. Reduced protein diets by exogenous protease supplements

To some degree, in reduced protein diets, dietary protein levels are determined by dietary standard ileal digestible (SID) lysine concentrations because other SID essential amino acids to SID lysine ratios are used in ideal amino acids profile. It is estimated that 5% SID lysine reduction will reduce dietary crude protein by 1% unit. In practice, the efficacy of protease is mainly determined by undigested protein concentration in feed ingredients. Usually when SID lysine (%) to undigested protein (%) ratio is lower than 0.3, dietary SID lysine and other essential amino acids could be reduced by 5% (Figure 4).

Figure 4. Bodyweight gain in male Ross 308 broilers from 22-35 days post-hatch (P = 0.061).

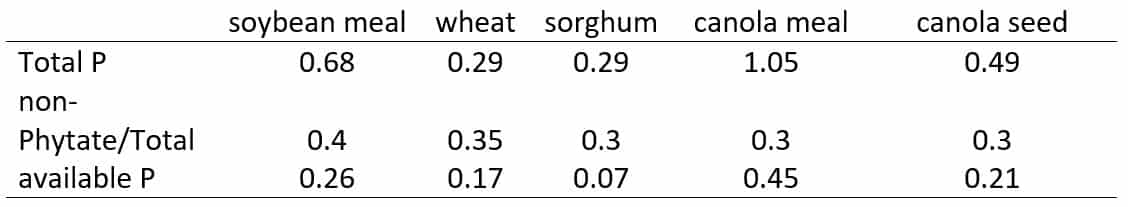

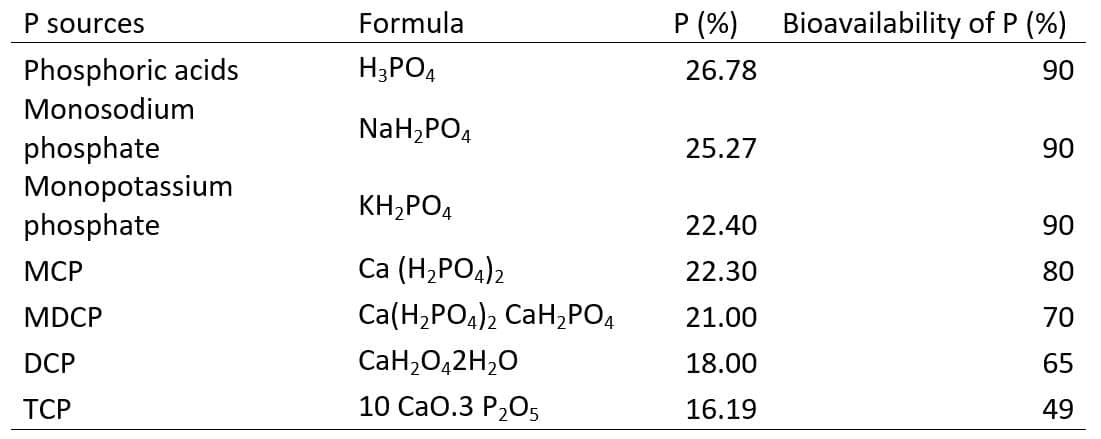

5. Phosphorus and phytase in reduced protein diets

In reduced protein diets, soybean meal and other protein ingredients will be partially replaced by grains and crystalline amino acids. Phytate phosphorus and available phosphorus variation in feed ingredients (Table 1) may increase inorganic phosphorus usage. We also need to reconsider phosphorus matrix value in phytase and absorption rate in inorganic phosphorus (Table 2). In table 1, it is clearly show that in sorghum-based diets, the matrix value of phosphorus in phytase may be higher than that in wheat-based diets, but it will be lower in reduced protein diets because of lower inclusion levels of soybean meal. In table 2, it is shown that when formulating reduced protein diets, both inorganic phosphorus contents and their bioavailability should be considered. In general, inorganic phosphorus bioavailability is strongly related to citric acid solubility and current DCP and MDCP practical bioavailability could be predicted by citric acid solubility.

Table 1. Total P and available P in feed ingredients (%)

Table 2. Phosphorus bioavailability from different sources

6. Nucleotide supplements in reduced protein diets

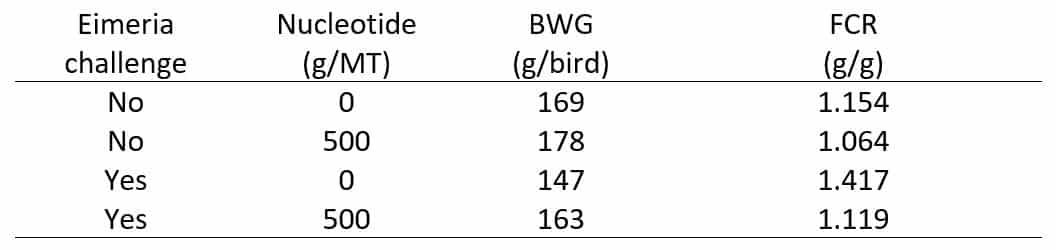

In reduced protein diets, almost all essential amino acids requirements could be met by adding crystalline amino acids. The reduced protein contents mainly come from non-essential amino acids concentration including glutamine and aspartic acids, which are precursors to produce nucleotides in the chicken body. In cocci vaccination and high-stock density stress situation, this exogenous production of nucleotides might not be sufficient to support a healthy immune system. Table 3 clearly shows that in Eimeria challenging situation, adding Nucleotides (IMP) significantly alleviate the challenging impact on chicken body weight gain (BWG) and feed conversion ratio (FCR)

Table 3. Effect of Nucleotides on chicken performance at d 11-15 after challenging

7. Gut health concern in reduced protein diets

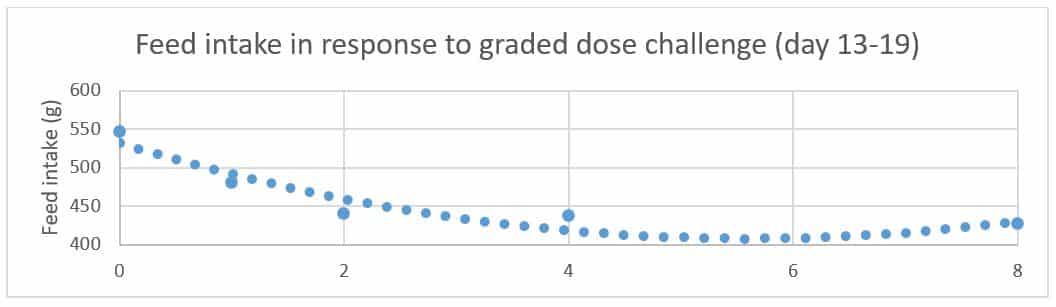

In Australia and USA, coccidiostats are considered as antibiotics and are banned in antibiotics free production. Currently in breeder and claimed antibiotics free chicken production, Eimeria vaccination has been widely practiced controlling cocci infection. However, broiler chicken feed intake is sufficiently reduced by the vaccination challenging dose and each double dose will worsen FCR by 9 points (Figure 5). Some new gut health related feed additives are necessary in reduced protein diets for young animals to fight against disease challenging.

Figure 5. Feed intake in response to graded dose Eimeria vaccination challenging

- Mannanase: Β-Mannan in soybean meal is one of the main antinational factors to decrease the efficiency of nutrient use. Supplementation of the exogenous mannanase has been demonstrated to increase chicken feed intake, significantly reduce coccidial lesion sores and increase breast production. Dietary AME can be saved by 50 kcal/kg due to reduced immune response sensitivity. The efficacy of Mannanase addition is strongly related to soybean meal inclusion levels and optimal crude fiber (%) to SID Lysine ratio is about 1.45 for Mannase response.

- Glucose oxidase: Cell-mediated immunity is thought to be important in the resistance of chickens to infection by coccidia. It has been demonstrated that sporozoites of Eimeria tenella are very sensitive to superoxide ions. Adding exogenous glucose oxidase to reduced protein diets could consume surplus oxygen and increase the shelf life of diets. More importantly, it can endogenously produce hydrogen peroxide to directly kill Eimeria and improve gut health. The heat tolerable glucose oxidase is commercially available now.

- Antimicrobial peptide: Previously it targets Gram negative bacteria such as E coli and Salmonella. Right now, new product is available to protect from Gram positive and negative bacteria infection including colostrum perfringens. Usually, Gram positive bacteria are acids resistance and organic acids are useless in Gram positive bacterial infection.

- Postbiotics: different from traditional probiotics, this postbiotics also includes metabolites from probiotics such as peptides, lipoprotein and bacteriocins, more widely building up the first defense line

- Tri-butyrin: it will promote the overall gut health by facilitating tight junction assembly.

8. Other concerns regarding to reduced protein diets

In reduced protein diets, feed grains such as wheat inclusions will usually increase at the expense of soybean meal. The current supplemental dosage of xylanase needs to be increased to completely degrade soluble Xylan in wheat and reduced viscosity.

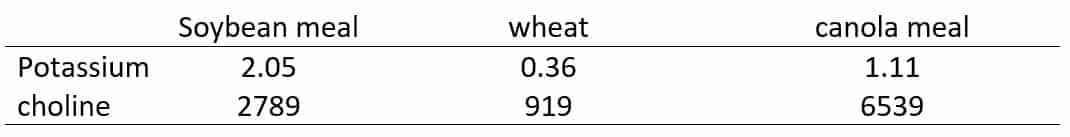

In addition, compared with wheat, soybean meal contains more potassium and choline (Table 4). Therefore, extra potassium bicarbonate or potassium chloride and choline chloride may be increased in reduced protein diets.

Table 4. Potassium and choline concentration in feed ingredients (%)

A study compiled by Redox Animal Nutritionists.

Exogenous protease supplementation in broiler chicken diets has primarily been attributed to improvements in protein and amino acids digestibility. Therefore, nutritionists can formulate diets with lower levels of dietary protein while maintaining growth performance.

In a typical wheat-soybean meal-based diet, a reduction of 1% in amino acids reduces feed cost by about 3 AUD/Mt.

The use of exogenous phytase in poultry feed is accepted globally, whilst non-starch polysaccharide enzymes (NSPases) such as xylanase and β-glucanase are commonly used in wheat- and barley-based diets, respectively. However, a combination of 3 or more exogenous feed enzymes is less common. A plethora of publications on protease are available, but reports on the effect of protease in diets that include both phytase and NSPases are less frequent. Recently, a deep litter study was conducted by the University of Sydney on wheat/soybean meal-based diets, including phytase, xylanase and protease at stocking densities similar to commercial practice within Australia.

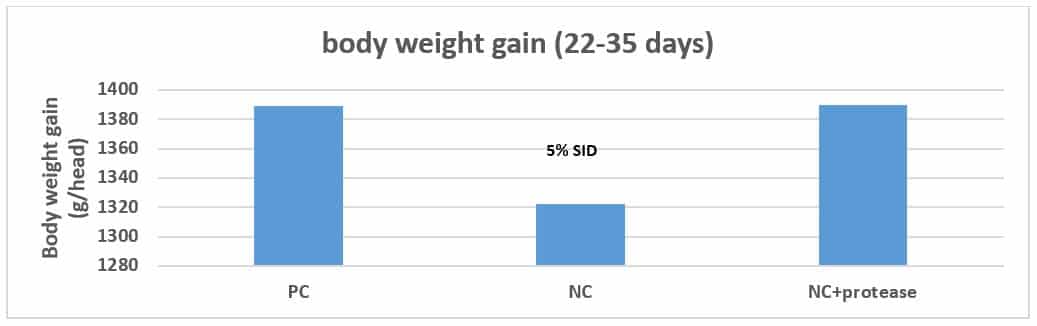

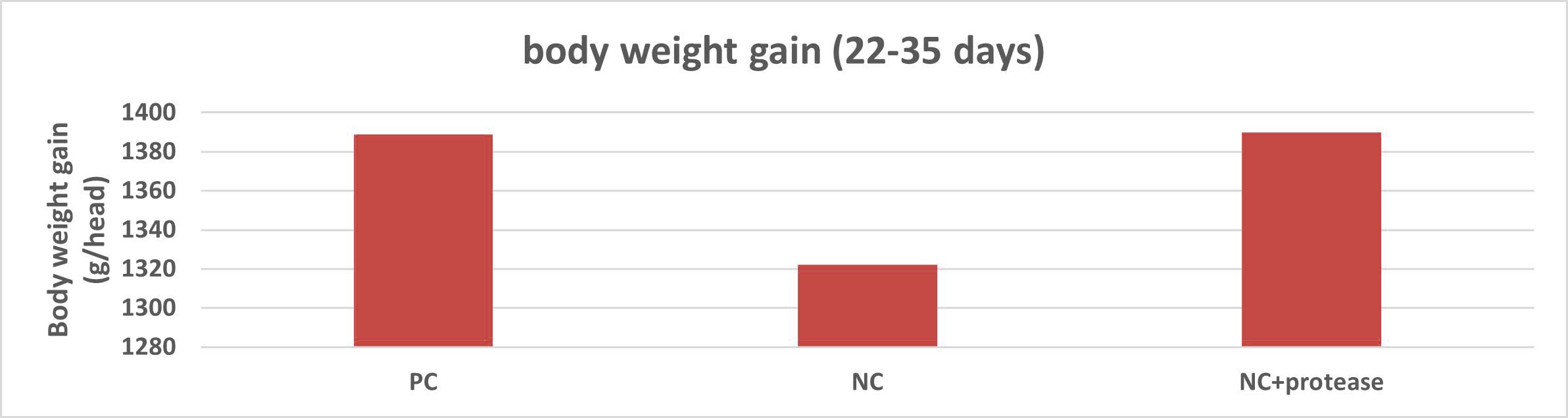

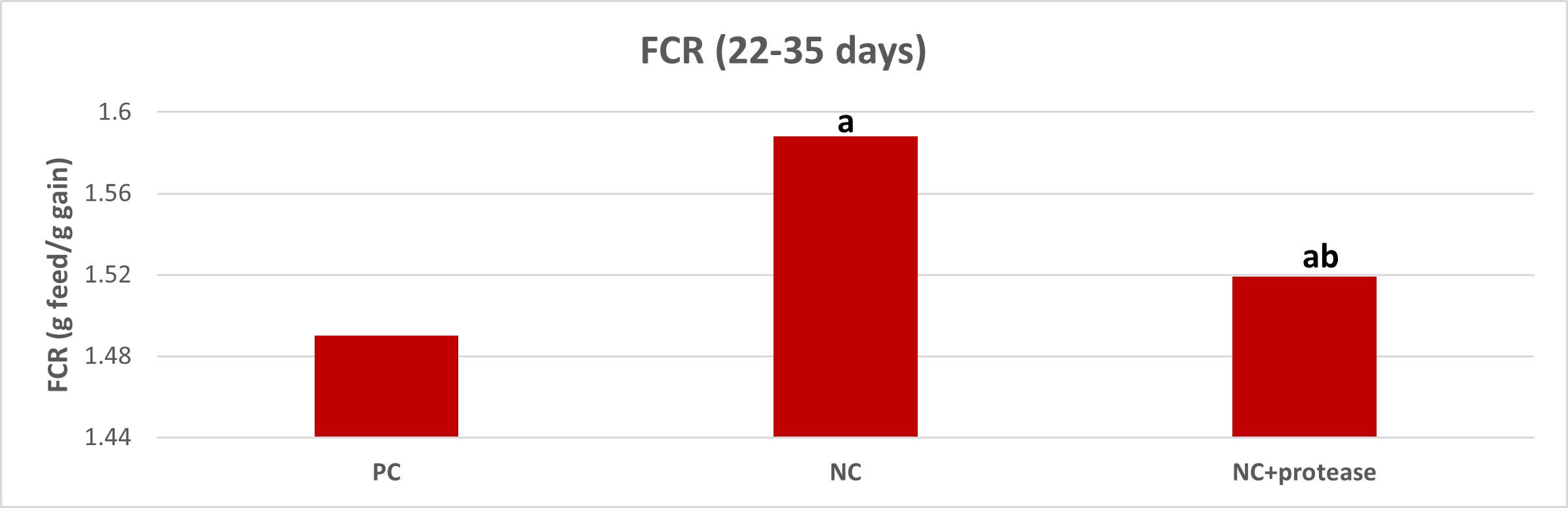

Standard, positive control (PC) diets were formulated to meet or exceed the 2019 Aviagen Ross 308 nutrition specifications and negative control (NC) diets were formulated with a 5% reduction in both crude protein and digestible essential amino acids. A third treatment group consisted of the NC supplemented with the exogenous protease. All diets contained 1000 FTU phytase and 4000 U of xylanase.

Overall broiler growth to 35 days post-hatch exceeded the Ross 2019 male performance objectives by 10.6% for weight gain (2580 versus 2333 g) and was superior by 5.66% in FCR (1.401 versus 1.485). There was a decline in bodyweight gain and inferior FCR when dietary protein was reduced by 5% (2644 versus 2513 g; P = 0.018 and 1.363 versus 1.432; P = 0.005, respectively). However, the addition of protease ameliorated the loss in performance (2583 g bodyweight gain and 1.408 FCR), and results in the finisher period are illustrated in Fig 1. and Fig 2. It is clearly shown that on the basis of phytase and xylanase, adding protease was able to improve amino acids digestibility further and recover 5% reductions in broiler finisher diet essential amino acids and crude protein without an adverse effect on broiler performance.

Fig 1. Bodyweight gain in male Ross 308 broilers from 22-35 days post-hatch (P = 0.061).

Fig 2. Feed conversion ratio in male Ross 308 broilers from 22-35 days post-hatch (P = 0.008).

Β-Mannan in soybean meal is one of the main antinational factors to decrease the efficiency of nutrient use. It has been found to be deleterious to broiler chicken performance, depressing chicken body weight gain and feed conversion ratio (FCR), as well as glucose and water absorption. Adding the exogenous mannanase has been demonstrated to improve chicken performance, significantly reduce coccidial lesion sores and increase egg production.

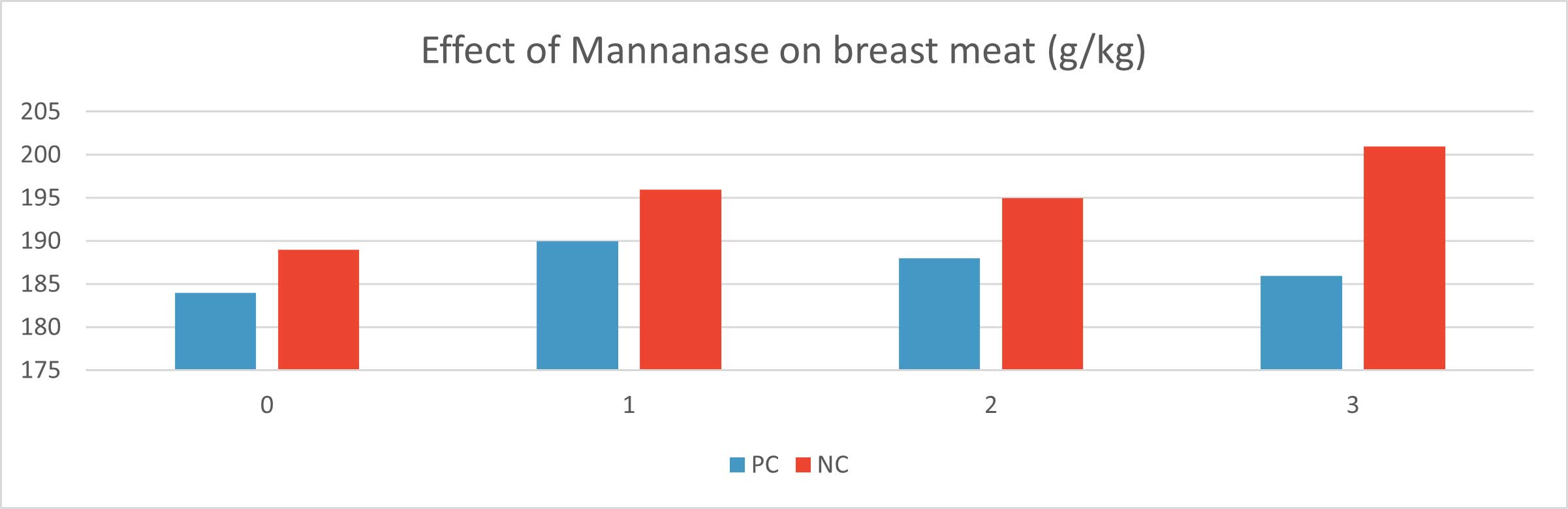

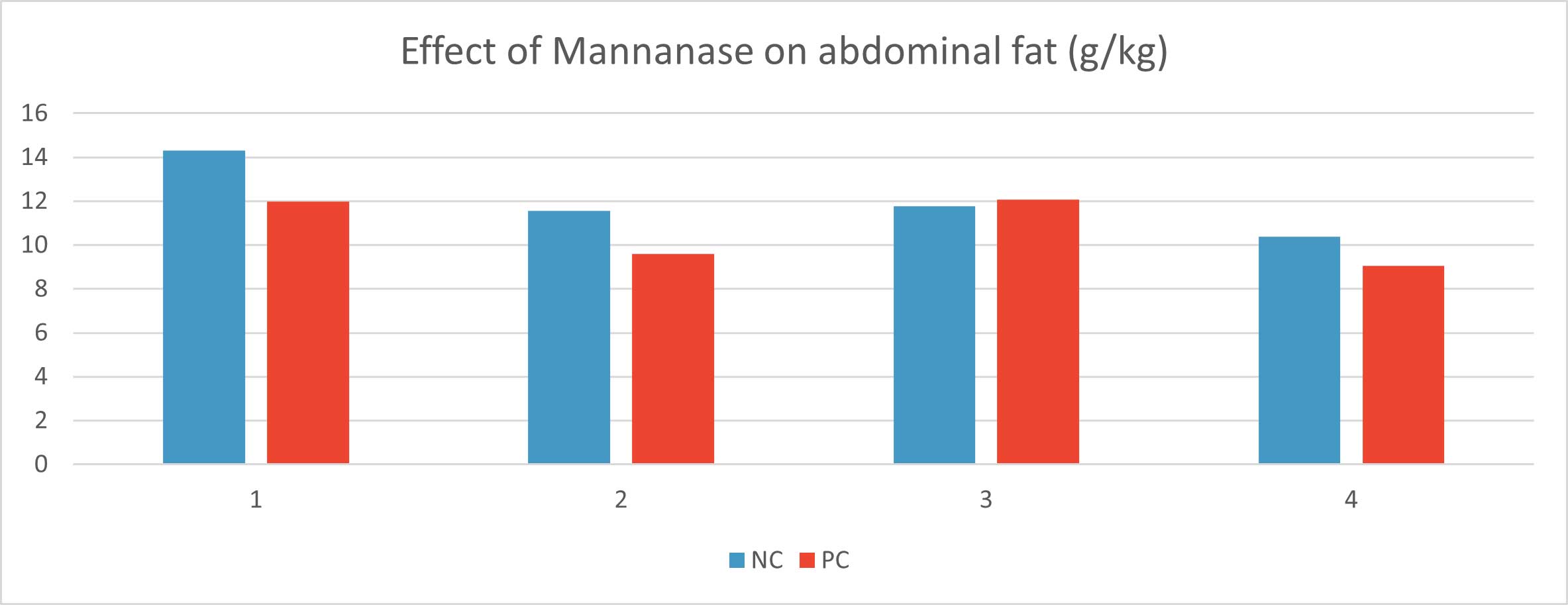

Recently, the University of Sydney conducted a broiler chicken trial to investigate the effect of the exogenous mannanase on broiler chicken performance and meat quality in reduced protein diets.

Standard, positive control (PC) diets were formulated to meet or exceed the 2019 Aviagen Ross 308 nutrition specifications and negative control (NC) diets were formulated with a 0.18 MJ in the starter and 0.21 MJ in grower and finisher phases. Another six treatments consisted of the PC and NC supplemented with the exogenous mannanase 100, 200 and 300 mg/kg, respectively. All eight diets contained 1000 FTU phytase.

Overall broiler growth to 35 days post-hatch exceeded the Ross 2019 male performance objectives by 23.6% for weight gain (2884 versus 2333 g) and was superior by 10.71% in FCR (1.326 versus 1.485). Adding 200 mg/kg β-Mannanase in low energy diets obtained better body weight gain and FCR compared with that in the normal standard diets. Interestingly, in the finishing period, adding β-mannanase to low density diets did not significantly increase feed intake but supported heavier breast meat (Figure 1); However, adding β-Mannanase to standard normal energy density diets significantly increased feed intake and consequent body weight gain but tended to reduced abdominal fat (Figure 2), indicating the dietary energy was efficiently used to produce chicken meat but not fat accumulation. Therefore, β-Mannanase supplementation could save both energy (50 kcal/kg) and amino acids (1% of all essential amino acids reduction).

Fig 1. Breast meat in male Ross 308 broilers from 0-35 days post-hatch (P = 0.111).

Fig 2. Abdominal fat contents in male Ross 308 broilers from 0-35 days post-hatch (P =0.117).

A study compiled by Dr Yumin Bao, Redox Animal Nutritionist.

Through a careful and detailed analysis of a customer’s crops, fertiliser application rates and exploring Redox’s range of products, we aim to deliver the best advice tailored specifically to each grower.

At Redox, we empower our Agronomists to drive success on the farm. Our experienced team of specialists are eager to find solutions that enable our partners in agriculture to optimise their yield and reduce costs while maintaining a high production level.

“I take great pride in the positive outcomes we produce on farms,” said veteran Redox Agronomist Ian Gardner.

“…our work and dedication on a Raspberry crop recently resulted in 25 tonnes per hectare within 18 months – exceeding what standard practices could have achieved alone! The farmer was thrilled with this result.”

“Watching over the Dolomia Plus Raspberry crop during its final harvest was a sight to behold. After six years in Adelaide Hills, South Australia, these resilient plants had defied an unseasonably cold winter and I walked through them recently when temperatures still hovered around 9 degrees Celsius – yet they endured proudly until their end of season finale.” Ian Gardner, Redox Agronomist.

Welcome aboard Diego

Diego Farias is our newest Agronomist; he hails from Brazil, bringing a wealth of knowledge and experience to Redox and boasts an impressive background and expertise. With his Bachelor’s Degree in Agriculture as well as honing his skills specializing in plant nutrition, he has gained invaluable experience from internships at soil and plant analysis laboratories to working with broad acre crops such soybean seed, cotton & corn for years.

In addition to this impressive work history Down Under he has been passionate about protected cropping (Tomato Capsicum Eggplant Cucumber etc.), providing agronomic aid for vegetable growers including managing soil/plant nutrition issues alongside pest & disease control plus hydroponic systems.

“Going on-site and meeting with our customers to understand what they need is crucial, but it’s also a wonderful way to connect with them and get to know them personally. Growing up on a farm, my love for agriculture goes back to being a young boy. I’m now driven by an unrelenting dedication and passion to share that knowledge with the growers who depend on me; together, we have forged strong relationships built of mutual understanding and respect,” says Diego Farias, our newly appointed Agronomist working out of our Adelaide office.

As innovators of new farm technologies and educators for existing practices, agronomists ensure that crops can be grown sustainably yet profitably — a crucial balance when it comes to protecting our planet’s future.

Our Redox Agronomists will

- Collect and analyse data and samples of produce, feed, and soil to study other factors affecting production.

- They will advise farmers about techniques for improving the production of crops, pest/weed control, soil improvement etc.

- They will also study environmental factors that affect commercial crop production, pasture growth & animal breeding and develop procedures and techniques for solving agricultural problems & improving production efficiency.

We offer an exciting environment for career-driven individuals who share our commitment towards progress and innovation.

If this sounds like you, we would love to hear from you.

Today is R U OK day and the message this year is: Ask R U OK? No qualifications needed. To support their great work Redox have committed to a monthly ongoing donation.

What is R U OK?

It’s an Australian non-profit suicide prevention organisation that revolves around the slogan “R U OK?” and advocates for people to have conversations with others.

The organisation has a dedicated R U OK? Day, held annually on the second Thursday of September, encourages Australians to connect with people who have emotional insecurity, address social isolation, and promote community cohesiveness.

R U OK? works collaboratively with suicide prevention and mental illness experts, government departments, corporate leaders, teachers, universities, students and community groups. Its activities also align with the Australian Government’s LIFE Framework.

Tips on how to ask?

Got a feeling that someone you know or care about it isn’t behaving as they normally would? Perhaps they seem out of sorts? More agitated or withdrawn? Or they’re just not themselves. Trust that gut instinct and act on it.

Learn more about the signs and when it’s time to ask here.

We can all make a difference in the lives of those who might be struggling by having regular, meaningful conversations about life ‘s ups and downs. If you feel like something’s not quite the same with someone you know – there’s something going on in their life or you notice a change in what they’re doing or saying – trust that gut instinct and take the time to ask.

The most straightforward way for you to get involved and help is to donate.

Every dollar helps.

Donate here.

The shipping market has been under immense pressure over the past year. We have seen shipping prices skyrocket and ships facing considerable delays for various reasons, most notably the pandemic. However, there is some good news on the horizon.

Shipping prices have stabilised, and shipping times have begun to improve. However, some significant uncertainties could still impact shipping in the coming months as we head into the traditional peak season for shipping. The biggest concerns are labour disputes at West Coast American ports and continued apprehension regarding COVID-19 policy within China.

Shipping during the peak season can be difficult for raw material providers as demand can grow 11-15%. The increased demand for consumer goods around the holiday season globally creates shipping issues for all, including those moving raw materials. This is because shipping lines do not prioritise raw materials over consumer goods.

Several ongoing labour disputes are affecting major ports globally, with dealers particularly prevalent on the West Coast of the USA and in some European countries. These disputes typically result in increased dwell time and can reduce the global capacity for large container vessels. One of the main issues causing concern is the looming expiration of port workers’ contracts on the West Coast of the USA in June. Data shows congestion is already starting to build up in Californian ports, with containers waiting for more than nine days on average – the highest figures seen year to date.

Port of Long Beach: The pandemic has put immense pressure on the shipping network, but dockworkers have continued to rise to the challenge. Their hard work has kept the US economy moving, even in difficult times.

In Europe, there is also an ongoing threat of trade action slowing down major feeder ports in the United Kingdom and Germany, which would have flow-on effects across the continent. While it is difficult to predict the outcome of these disputes, it is clear that they are having a significant impact on global trade.

The appearance of the Omicron strain in China led to a 70-day lockdown of Shanghai, which resulted in delays for 20% of the world’s container ships. This had a significant impact on the ability of suppliers to manufacturing goods globally. Another lockdown could occur in any city, province or port, which would further delays and disruptions. The continued zero COVID-19 policy in China is an ongoing, difficult to predictable variable in global shipping.

Despite the challenges of 2020, the shipping industry has shown its resilience in the face of disruption. And while the worst of the COVID-19-induced supply disruptions may be over, it is crucial to be prepared for continued uncertainty ahead. The good news is that carriers are already planning for the 2022 shipping peak season and are implementing measures to avoid a repeat of last year’s disruption.

It is essential to discuss strategies to mitigate shipping issues with your sales representative and book stock well ahead of time to minimise risk. Doing so can help ensure that your materials arrive promptly and without incident.

Redox has reaffirmed our commitment to the health, safety, and security of our employees, community, and the environment, by successfully passing NACD’s Responsible Distribution® verification for the current three-year cycle.

Responsible Distribution is the National Association of Chemical Distributor’s (NACD) third-party-verified environmental, health, safety, and security program. It allows members to demonstrate their pledge to continuous performance improvement in chemical storage, handling, transportation, and disposal.

In December 1991, the member companies of NACD undertook as its most important mission the inception of Responsible Distribution, developed by NACD members for NACD members.

Responsible Distribution is a mandatory third-party verified environmental, health, safety & security program that lets members demonstrate their commitment to continuous performance improvement in every phase of chemical storage, handling, transportation, and disposal.

NACD members play a leadership role in their communities as information resources. They are eager to provide the same assistance and guidance to local, state, and federal legislators on technical issues relating to the safe handling, storage, transportation, use, and disposal of chemical products.

Key Benefits of Responsible Distribution

- Lower occurrences of safety and environmental incidents

- Enjoy better documentation of company policies

- Employ practices of excellence and quality systems throughout your operations

- Engage in better communication with local communities

- Reduce audit costs and time spent on audits

- Save on insurance expenses

- Improve marketplace visibility and earn credibility through performance

“Responsible Distribution is critical to the chemical distribution industry’s ability to safely deliver more than 30 million tons of product every year,” said NACD President and CEO Eric R. Byer.

“Through their successful verification, Redox and its senior leadership have committed to continuous improvement in the responsible management and handling of chemicals that ensures NACD members effectively support the industries America relies on most, such as agriculture, healthcare, oil and gas, manufacturing equipment, and many others.”

Please click here to view NACD Responsible Distribution’s Guiding Principles.

Our Partnering Manufacturers